Notes: Pipe diameters: 4 - 6 - 8 - 10 - 12 mm

Nominal pressure: 100 bar (1450 psi)

Pipe diameters: 6 - 8 - 10 - 12 mm

Nominal pressure: 315 bar (4569 psi)

Pipe diameters: 15 - 18 - 22 - 28 - 35 - 42 mm

Nominal pressure: 160 bar (2320 psi)

Pipe diameters: 6 - 8 - 10 - 12 - 14 - 16 - 20 mm

Nominal pressure: 630 bar (9137 psi)

Pipe diameters: 25 - 30 mm

Nominal pressure: 400 bar (5802 psi)

Pipe diameter: 38 mm

Nominal pressure: 315 bar (4569 psi)

Important note: The images and information contained in this Series may be subject to change without notice. The technical and dimensional data are purely indicative and may change over time.

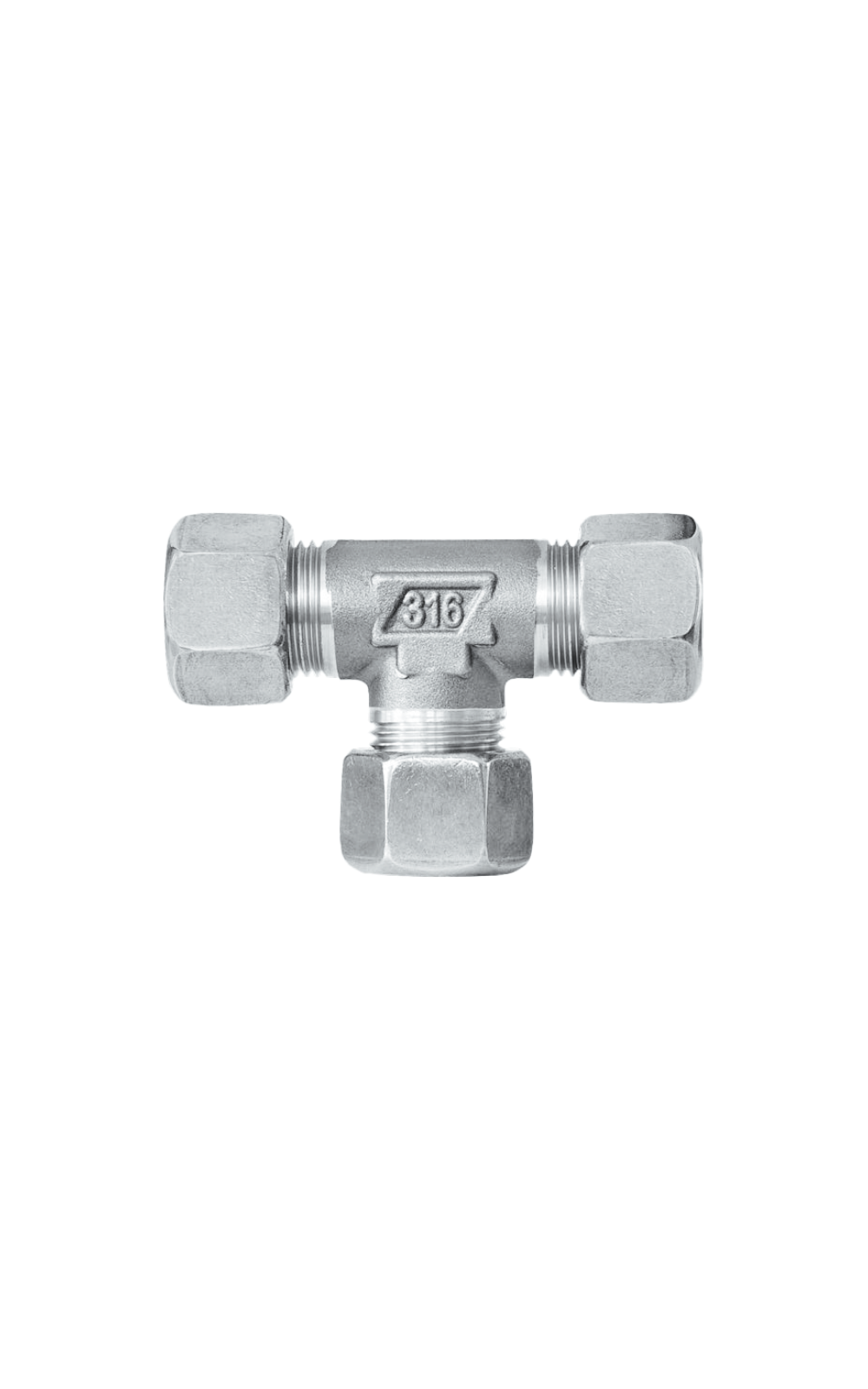

The Series

05000 X-TREME PRO offers a complete range of DIN 2353 compression

fittings made of AISI 316 stainless steel, designed for high-pressure

car wash systems and hydraulic or industrial installations subject to harsh

conditions.

Both the body and nut are made of AISI 316L Ti, while the

internal cutting ring is crafted from treated AISI 316L, ensuring

reliable sealing performance under significant mechanical stress. The entire

product line is manufactured in full compliance with CE regulations,

guaranteeing adherence to the strictest European safety and pressure equipment

standards.

These

fittings are ideal for weld-free connections of high-pressure steel tubing

in accordance with DIN/ISO 1127 D4 class, with minimal dimensional tolerances

(±0.1 mm) and a maximum surface hardness of 90 HRB. Thread options

include ISO 228 (BSP cylindrical), ISO 7 (BSPT tapered), and DIN 13 (metric),

ensuring compatibility across multiple system types.

Available

in LL (extra-light), L (light), and S (heavy) series, these fittings

cover a full range of nominal pressures from 100 to 630 bar (1450 ÷ 9137

psi), with corresponding tube diameters. Operating temperatures

range from –60°C to +400°C (–76°F ÷ +752°F), or –20°C to +200°C (–4°F ÷ +392°F)

when using RBX sealing gaskets, providing outstanding durability in both hot

and cold environments.

Technical features:

FULL AISI 316 STAINLESS STEEL ACCORDING TO DIN 2353 STANDARD

Each fitting is made entirely from AISI 316L Ti stainless steel, ensuring maximum compatibility with high-pressure installations in harsh environments.

SUITABLE FOR HIGH PRESSURE APPLICATIONS

The LL, L, and S series cover a wide pressure range up to 630 bar (9137 psi), maintaining high reliability and safety standards.

PERFECT FOR SEAMLESS CONNECTIONS OF STEEL TUBES

Designed for hydraulic and car wash systems, these compression fittings guarantee secure sealing without welding or additional machining.

The Series

05000 X-TREME PRO offers a complete range of DIN 2353 compression

fittings made of AISI 316 stainless steel, designed for high-pressure

car wash systems and hydraulic or industrial installations subject to harsh

conditions.

Both the body and nut are made of AISI 316L Ti, while the

internal cutting ring is crafted from treated AISI 316L, ensuring

reliable sealing performance under significant mechanical stress. The entire

product line is manufactured in full compliance with CE regulations,

guaranteeing adherence to the strictest European safety and pressure equipment

standards.

These

fittings are ideal for weld-free connections of high-pressure steel tubing

in accordance with DIN/ISO 1127 D4 class, with minimal dimensional tolerances

(±0.1 mm) and a maximum surface hardness of 90 HRB. Thread options

include ISO 228 (BSP cylindrical), ISO 7 (BSPT tapered), and DIN 13 (metric),

ensuring compatibility across multiple system types.

Available

in LL (extra-light), L (light), and S (heavy) series, these fittings

cover a full range of nominal pressures from 100 to 630 bar (1450 ÷ 9137

psi), with corresponding tube diameters. Operating temperatures

range from –60°C to +400°C (–76°F ÷ +752°F), or –20°C to +200°C (–4°F ÷ +392°F)

when using RBX sealing gaskets, providing outstanding durability in both hot

and cold environments.

Technical features:

FULL AISI 316 STAINLESS STEEL ACCORDING TO DIN 2353 STANDARD

Each fitting is made entirely from AISI 316L Ti stainless steel, ensuring maximum compatibility with high-pressure installations in harsh environments.

SUITABLE FOR HIGH PRESSURE APPLICATIONS

The LL, L, and S series cover a wide pressure range up to 630 bar (9137 psi), maintaining high reliability and safety standards.

PERFECT FOR SEAMLESS CONNECTIONS OF STEEL TUBES

Designed for hydraulic and car wash systems, these compression fittings guarantee secure sealing without welding or additional machining.