Notes:

Pipe diameters: 4 - 6 - 8 - 10 - 12 mm

Nominal pressure: 100 bar (1450 psi)

Pipe diameters: 6 - 8 - 10 - 12 mm

Nominal pressure: 315 bar (4569 psi)

Pipe diameters: 15 - 18 - 22 - 28 - 35 - 42 mm

Nominal pressure: 160 bar (2320 psi)

Pipe diameters: 6 - 8 - 10 - 12 - 14 - 16 - 20 mm

Nominal pressure: 630 bar (9137 psi)

Pipe diameters: 25 - 30 mm

Nominal pressure: 400 bar (5802 psi)

Pipe diameter: 38 mm

Nominal pressure: 315 bar (4569 psi)

Important

note: The images and information contained in this Series may be subject to

change without notice. The technical and dimensional data are purely indicative

and may change over time.

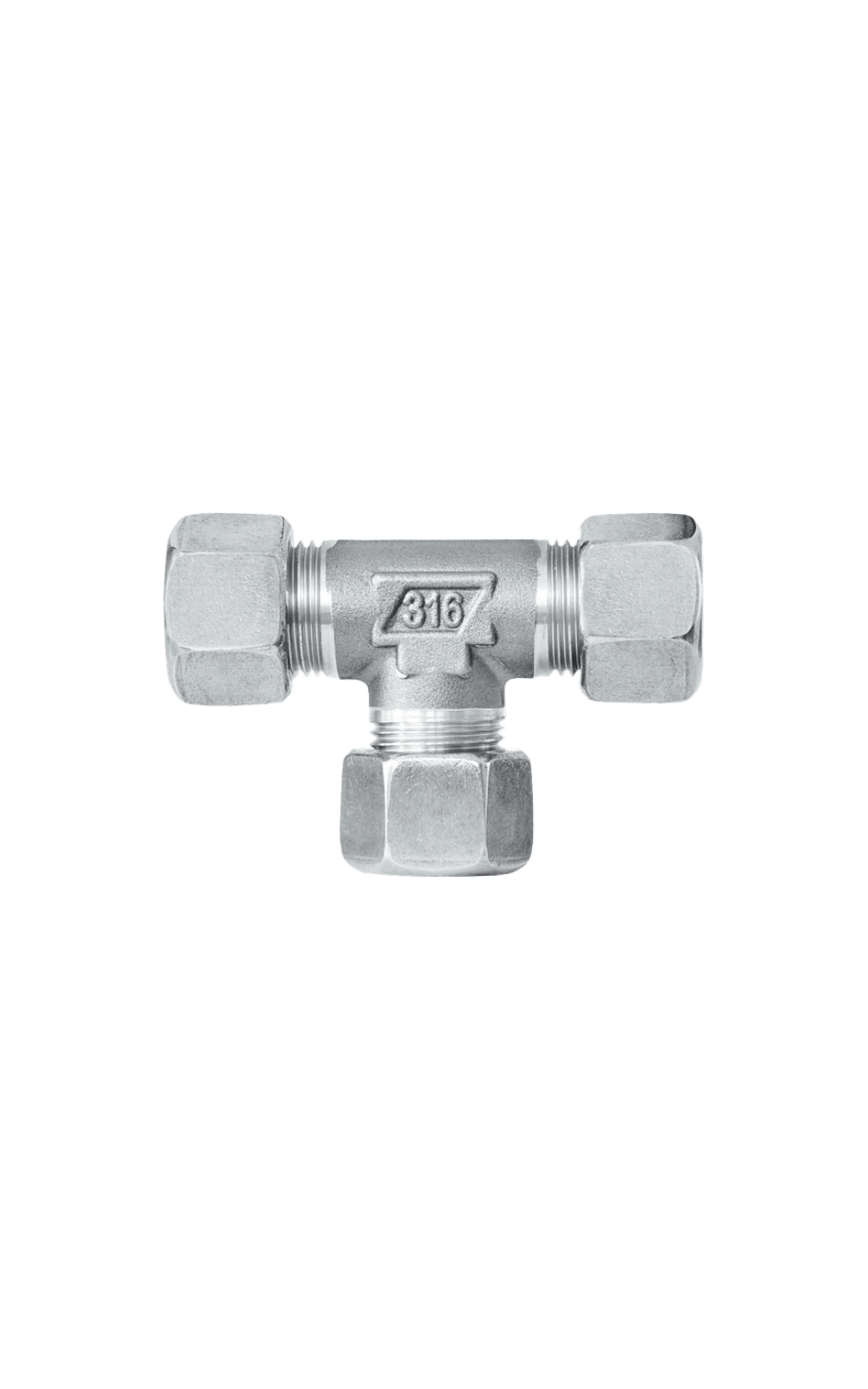

The 05000

Series DIN 2353 compression fittings in AISI 316 stainless steel are the

best solution for industrial and professional systems requiring reliability,

mechanical strength, and long-term durability even under the harshest

conditions.

Each fitting features a body and nut made of AISI 316L Ti

stainless steel and a treated AISI 316L stainless steel cutting ring,

ensuring secure sealing by cutting ring and full compliance with the DIN

2353 standard.

These

fittings are especially suitable for hydraulic and oleodynamic systems

operating at high working pressures and demanding temperatures, offering

safety and consistent performance even with vibrations or thermal

cycles. The weldless design allows for quick and reliable connections,

minimizing installation time and making maintenance easier.

The 05000 Series

is compatible with air, water, oil, aggressive fluids, and harsh

environments, and can also be used with other fluids provided compatibility

with construction materials is verified.

Available

in three robustness categories, the 05000 Series covers all application

requirements: LL Series (ultralight) for pipe diameters from 4 to 12 mm

with a nominal pressure of 100 bar (1450 psi), L Series (light) for

diameters from 6 to 12 mm up to 315 bar (4569 psi) and from 15 to 42 mm up to

160 bar (2320 psi), and S Series (heavy) from 6 to 20 mm for 630 bar

(9137 psi), from 25 to 30 mm for 400 bar (5802 psi), and 38 mm for 315 bar

(4569 psi). The operating temperature range is -60°C to +400°C

(-76°F ÷ +752°F), while with RBX gaskets it is -20°C to +200°C (-4°F ÷ +392°F).

Available threads include ISO 228 (BSP) cylindrical

gas, ISO 7 (BSPT) conical gas, and DIN 13 cylindrical metric. Pipe

compatibility is ensured for high-pressure steel pipes according to DIN/ISO

1127 D4 class (±0.1% external nominal diameter with a minimum tolerance of ±0.1

mm). The maximum surface hardness is 90 HRB, guaranteeing high

resistance and safety even under significant mechanical stress. All fittings in

the 05000 Series are CE and MOCA certified, ensuring full compliance

with European standards for industrial and food & beverage applications.

Technical features:

Fluids: air, water, oil, aggressive fluids and environment, other fluids upon verification.

FULLY MADE OF AISI 316 STAINLESS STEEL ACCORDING TO DIN 2353 STANDARD

These compression fittings are manufactured exclusively from AISI 316 stainless steel and feature a secure cutting ring seal, fully compliant with the DIN 2353 standard.

SUITABLE FOR HIGH PRESSURES AND TEMPERATURES

They are particularly suitable for hydraulic and oleodynamic systems operating under high working pressures and challenging temperatures, ensuring safety, performance, and long-lasting reliability.

SUITABLE FOR WELDLESS CONNECTIONS OF STAINLESS STEEL PIPES AND FOR AGGRESSIVE FLUIDS

These fittings allow for reliable weldless connections and are suitable for air, water, oil, aggressive fluids, and harsh environments, offering versatility with other fluids upon prior compatibility check.

The 05000

Series DIN 2353 compression fittings in AISI 316 stainless steel are the

best solution for industrial and professional systems requiring reliability,

mechanical strength, and long-term durability even under the harshest

conditions.

Each fitting features a body and nut made of AISI 316L Ti

stainless steel and a treated AISI 316L stainless steel cutting ring,

ensuring secure sealing by cutting ring and full compliance with the DIN

2353 standard.

These

fittings are especially suitable for hydraulic and oleodynamic systems

operating at high working pressures and demanding temperatures, offering

safety and consistent performance even with vibrations or thermal

cycles. The weldless design allows for quick and reliable connections,

minimizing installation time and making maintenance easier.

The 05000 Series

is compatible with air, water, oil, aggressive fluids, and harsh

environments, and can also be used with other fluids provided compatibility

with construction materials is verified.

Available

in three robustness categories, the 05000 Series covers all application

requirements: LL Series (ultralight) for pipe diameters from 4 to 12 mm

with a nominal pressure of 100 bar (1450 psi), L Series (light) for

diameters from 6 to 12 mm up to 315 bar (4569 psi) and from 15 to 42 mm up to

160 bar (2320 psi), and S Series (heavy) from 6 to 20 mm for 630 bar

(9137 psi), from 25 to 30 mm for 400 bar (5802 psi), and 38 mm for 315 bar

(4569 psi). The operating temperature range is -60°C to +400°C

(-76°F ÷ +752°F), while with RBX gaskets it is -20°C to +200°C (-4°F ÷ +392°F).

Available threads include ISO 228 (BSP) cylindrical

gas, ISO 7 (BSPT) conical gas, and DIN 13 cylindrical metric. Pipe

compatibility is ensured for high-pressure steel pipes according to DIN/ISO

1127 D4 class (±0.1% external nominal diameter with a minimum tolerance of ±0.1

mm). The maximum surface hardness is 90 HRB, guaranteeing high

resistance and safety even under significant mechanical stress. All fittings in

the 05000 Series are CE and MOCA certified, ensuring full compliance

with European standards for industrial and food & beverage applications.

Technical features:

Fluids: air, water, oil, aggressive fluids and environment, other fluids upon verification.

FULLY MADE OF AISI 316 STAINLESS STEEL ACCORDING TO DIN 2353 STANDARD

These compression fittings are manufactured exclusively from AISI 316 stainless steel and feature a secure cutting ring seal, fully compliant with the DIN 2353 standard.

SUITABLE FOR HIGH PRESSURES AND TEMPERATURES

They are particularly suitable for hydraulic and oleodynamic systems operating under high working pressures and challenging temperatures, ensuring safety, performance, and long-lasting reliability.

SUITABLE FOR WELDLESS CONNECTIONS OF STAINLESS STEEL PIPES AND FOR AGGRESSIVE FLUIDS

These fittings allow for reliable weldless connections and are suitable for air, water, oil, aggressive fluids, and harsh environments, offering versatility with other fluids upon prior compatibility check.