Ways: 2/2

Notes:

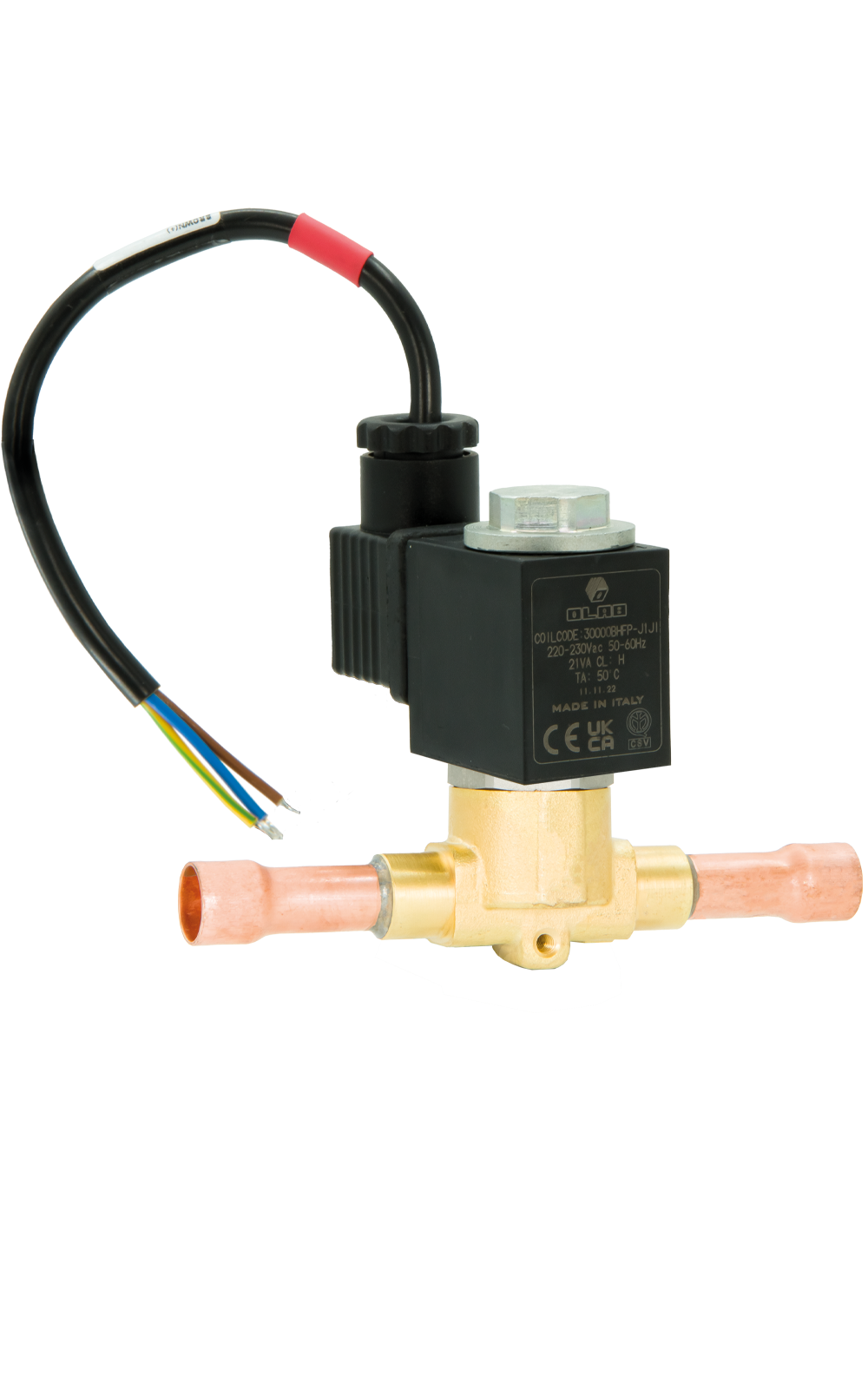

The Series

30500 normally open 2/2-way solenoid valves are engineered for professional

refrigeration systems using A1 refrigerants, delivering reliable, inspectable

performance in demanding applications.

Featuring a brass body and a stainless

steel AISI 303 tube machined from solid bar stock, these valves ensure

exceptional mechanical strength thanks to their thicker wall construction,

offering enhanced durability compared to standard thin-walled designs. The sealing

system in PTFE with NBR O-rings guarantees consistent and leak-free

operation even under intense thermal and pressure conditions.

A key

feature is the 36 mm coil with ø14 mm bore, built to insulation class

H (180°C) and equipped with a double O-ring system, providing

superior thermal resistance and insulation protection. Designed with IP67

protection rating, the valve is certified by UL, ensuring full

protection against dust ingress and temporary water immersion, in compliance

with international safety standards.

Every unit

undergoes 100% helium leak testing in an advanced facility, ensuring

absolute reliability. The laser marking of each valve records the test

date and serial number, enabling permanent traceability of the tested

performance throughout its service life.

Operating

in a wide thermal range from –35°C to +105°C (–31°F to +221°F) and

withstanding pressures up to 52 bar (754 psi), the SERIES 30500 solenoid

valve complies with CE, IP67, and UL certifications, making it an ideal

choice for high-quality, professional-grade refrigeration systems.

Technical features:

COMPATIBLE A1 REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a

HFO e miscele HFO/HFC: R1234ze, R448A, R449A, R450A, R452A, R1234yf, R1233zdOur Neoprene compound gaskets have been designed and produced to be compatible with group A1 refrigerant gases (as defined in ASHRAE standard 34).However, in consideration of the infinite application variables (pressure, temperature and mixing percentages), an application check on the system is always required.

EXCEPTIONALLY ROBUST

The sleeve, made from AISI 303 stainless steel and machined from solid bar, features a greater wall thickness than traditional sleeves made from thin metal sheets, ensuring superior mechanical strength and long-term durability.

IP67 CERTIFIED SAFETY

Rated IP67 and UL certified, the valve guarantees complete protection against dust ingress and temporary water immersion, in compliance with international standards.

CLASS H Ø36 MM COIL WITH DOUBLE O-RING SEALING

The 36 mm coil, thermally insulated in Class H (180°C), is equipped with dual O-Ring sealing, ensuring high resistance to temperature and excellent sealing integrity.

100% HELIUM TESTED

Each unit is individually tested in a state-of-the-art helium facility. Date and serial number are engraved to certify compliance and allow full traceability of recorded performance data.

Solenoid valves can be installed anywhere in the system provided that the cooling capacity of all different models is taken into account. The device must be installed ensuring that the refrigerant flows in the direction shown by the arrows on the valve body. All models of this series can be mounted in all positions except for the one with a coil turned downwards. Brazing of valves to weldable pipes must be carried out using an alloy with low melting point. To avoid damages, make sure the flame is not pointed to the body during pipe welding. Before connecting the device make sure the operating data shown on the coil correspond to those on the system. Please read enclosed leaflet before proceeding with the installation.

The Series

30500 normally open 2/2-way solenoid valves are engineered for professional

refrigeration systems using A1 refrigerants, delivering reliable, inspectable

performance in demanding applications.

Featuring a brass body and a stainless

steel AISI 303 tube machined from solid bar stock, these valves ensure

exceptional mechanical strength thanks to their thicker wall construction,

offering enhanced durability compared to standard thin-walled designs. The sealing

system in PTFE with NBR O-rings guarantees consistent and leak-free

operation even under intense thermal and pressure conditions.

A key

feature is the 36 mm coil with ø14 mm bore, built to insulation class

H (180°C) and equipped with a double O-ring system, providing

superior thermal resistance and insulation protection. Designed with IP67

protection rating, the valve is certified by UL, ensuring full

protection against dust ingress and temporary water immersion, in compliance

with international safety standards.

Every unit

undergoes 100% helium leak testing in an advanced facility, ensuring

absolute reliability. The laser marking of each valve records the test

date and serial number, enabling permanent traceability of the tested

performance throughout its service life.

Operating

in a wide thermal range from –35°C to +105°C (–31°F to +221°F) and

withstanding pressures up to 52 bar (754 psi), the SERIES 30500 solenoid

valve complies with CE, IP67, and UL certifications, making it an ideal

choice for high-quality, professional-grade refrigeration systems.

Technical features:

COMPATIBLE A1 REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a

HFO e miscele HFO/HFC: R1234ze, R448A, R449A, R450A, R452A, R1234yf, R1233zdOur Neoprene compound gaskets have been designed and produced to be compatible with group A1 refrigerant gases (as defined in ASHRAE standard 34).However, in consideration of the infinite application variables (pressure, temperature and mixing percentages), an application check on the system is always required.

EXCEPTIONALLY ROBUST

The sleeve, made from AISI 303 stainless steel and machined from solid bar, features a greater wall thickness than traditional sleeves made from thin metal sheets, ensuring superior mechanical strength and long-term durability.

IP67 CERTIFIED SAFETY

Rated IP67 and UL certified, the valve guarantees complete protection against dust ingress and temporary water immersion, in compliance with international standards.

CLASS H Ø36 MM COIL WITH DOUBLE O-RING SEALING

The 36 mm coil, thermally insulated in Class H (180°C), is equipped with dual O-Ring sealing, ensuring high resistance to temperature and excellent sealing integrity.

100% HELIUM TESTED

Each unit is individually tested in a state-of-the-art helium facility. Date and serial number are engraved to certify compliance and allow full traceability of recorded performance data.

Solenoid valves can be installed anywhere in the system provided that the cooling capacity of all different models is taken into account. The device must be installed ensuring that the refrigerant flows in the direction shown by the arrows on the valve body. All models of this series can be mounted in all positions except for the one with a coil turned downwards. Brazing of valves to weldable pipes must be carried out using an alloy with low melting point. To avoid damages, make sure the flame is not pointed to the body during pipe welding. Before connecting the device make sure the operating data shown on the coil correspond to those on the system. Please read enclosed leaflet before proceeding with the installation.