Notes:

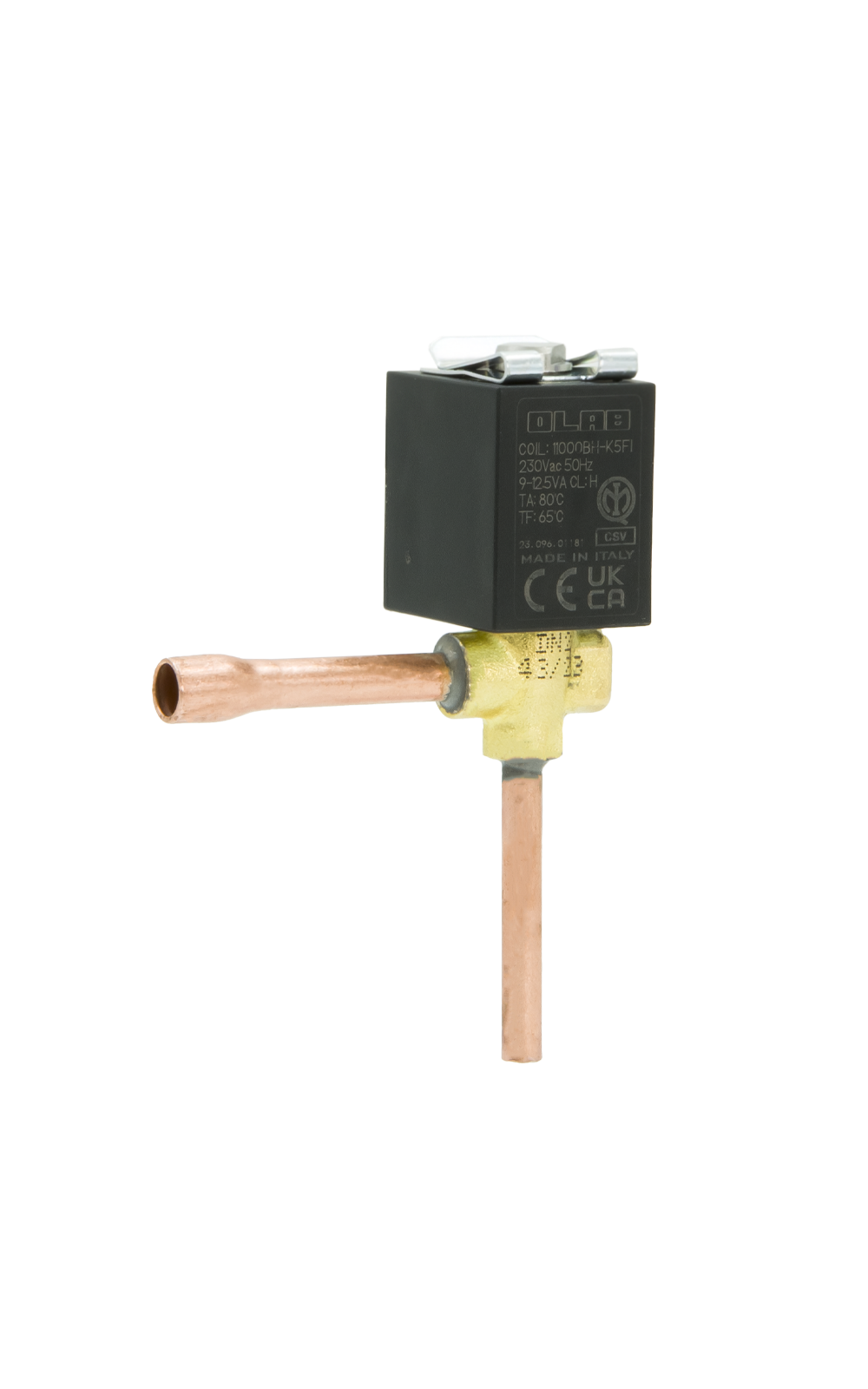

The Series

K09200 includes normally closed solenoid valves designed for use in small

A1 refrigeration systems, offering compact dimensions, operational

reliability, and easy integration.

The yellow brass body combined with copper

tubes ensures mechanical strength and compatibility with most A1

refrigerants. The non-inspectable brass tube incorporates a PTFE

sealing system with OLAB-certified 100% PFAS-FREE HNBR O-rings, ensuring leak-free

performance even under thermal stress.

The 22

mm coil with ø10 mm bore, rated for insulation class H (180°C), is

secured with a locking clip, allowing for adjustable orientation

during installation. The upper part of the coil is insulated by a

dedicated O-ring, while sealing between the body and fixed core is also

ensured by an O-ring, offering complete leak protection.

Available

in two configurations:

• DN Ø1.5 mm, KV 0.08 m³/h, M.O.P.D. 30 bar

• DN Ø2.0 mm, KV 0.12 m³/h, M.O.P.D. 25 bar

Both

versions operate with a nominal pressure (PS) of 30 bar (435 psi) and a

temperature range of –35°C to +65°C (–31°F ÷ +149°F). Fully CE

certified, the Series K09200 is ideal for OEM applications and compact

systems requiring high performance in limited space.

Technical features:

COMPATIBLE A1 REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a

HFO e miscele HFO/HFC: R1234ze, R448A, R449A, R450A, R452A, R1234yf, R1233zdOur Neoprene compound gaskets have been designed and produced to be compatible with group A1 refrigerant gases (as defined in ASHRAE standard 34).However, in consideration of the infinite application variables (pressure, temperature and mixing percentages), an application check on the system is always required.

RELIABLE SEALING BETWEEN BODY AND FIXED CORE

Tightness ensured by an O-ring placed between the valve body and the fixed core, preventing any leakage.

UPPER SIDE OF COIL INSULATED BY O-RING

The upper part of the coil is sealed with an O-ring to enhance thermal insulation and extend service life.

ADJUSTABLE COIL WITH LOCKING CLIP

The coil is secured by a locking clip, allowing for flexible orientation based on installation needs.

The Series

K09200 includes normally closed solenoid valves designed for use in small

A1 refrigeration systems, offering compact dimensions, operational

reliability, and easy integration.

The yellow brass body combined with copper

tubes ensures mechanical strength and compatibility with most A1

refrigerants. The non-inspectable brass tube incorporates a PTFE

sealing system with OLAB-certified 100% PFAS-FREE HNBR O-rings, ensuring leak-free

performance even under thermal stress.

The 22

mm coil with ø10 mm bore, rated for insulation class H (180°C), is

secured with a locking clip, allowing for adjustable orientation

during installation. The upper part of the coil is insulated by a

dedicated O-ring, while sealing between the body and fixed core is also

ensured by an O-ring, offering complete leak protection.

Available

in two configurations:

• DN Ø1.5 mm, KV 0.08 m³/h, M.O.P.D. 30 bar

• DN Ø2.0 mm, KV 0.12 m³/h, M.O.P.D. 25 bar

Both

versions operate with a nominal pressure (PS) of 30 bar (435 psi) and a

temperature range of –35°C to +65°C (–31°F ÷ +149°F). Fully CE

certified, the Series K09200 is ideal for OEM applications and compact

systems requiring high performance in limited space.

Technical features:

COMPATIBLE A1 REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a

HFO e miscele HFO/HFC: R1234ze, R448A, R449A, R450A, R452A, R1234yf, R1233zdOur Neoprene compound gaskets have been designed and produced to be compatible with group A1 refrigerant gases (as defined in ASHRAE standard 34).However, in consideration of the infinite application variables (pressure, temperature and mixing percentages), an application check on the system is always required.

RELIABLE SEALING BETWEEN BODY AND FIXED CORE

Tightness ensured by an O-ring placed between the valve body and the fixed core, preventing any leakage.

UPPER SIDE OF COIL INSULATED BY O-RING

The upper part of the coil is sealed with an O-ring to enhance thermal insulation and extend service life.

ADJUSTABLE COIL WITH LOCKING CLIP

The coil is secured by a locking clip, allowing for flexible orientation based on installation needs.