Notes:

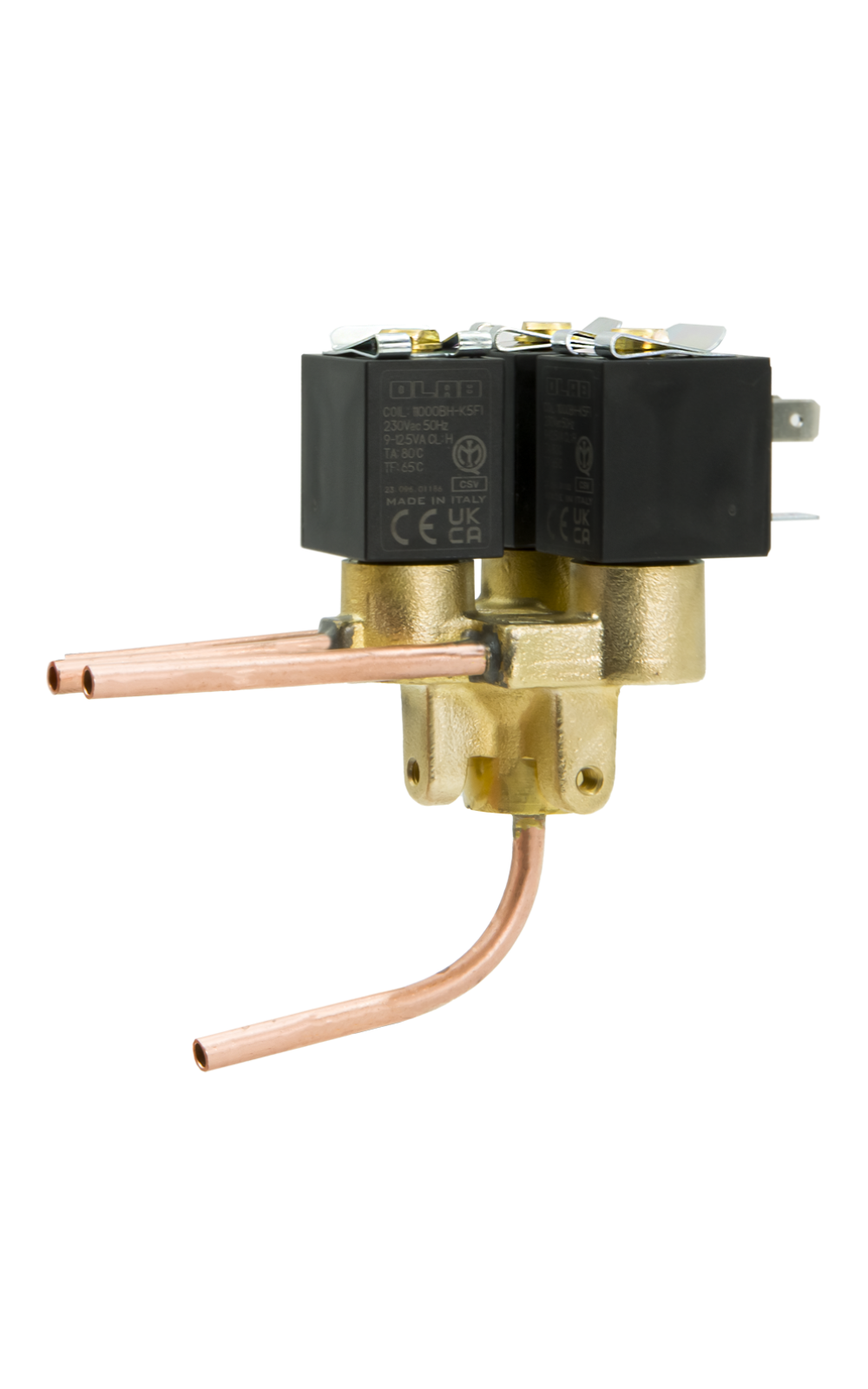

The Series

11000 solenoid valves are designed for small A1 refrigeration systems and

are available in a normally closed configuration, with yellow brass body

and copper pipes. They are offered in straight, L-shaped, or 2- and 3-valve

block versions, to ensure installation flexibility.

The inspectable

design allows for fast maintenance, and sealing is guaranteed by a PTFE

gasket and OLAB-certified neoprene O-ring.

The tube is

made of brass, and the 22 mm Ø10 coil, with H-class insulation

(180°C), includes a double O-ring and is fixed with a rotatable clip. The coil’s

upper and lower side is further insulated through dedicated O-rings,

ensuring durability and performance over time.

The Series 11000 valves are 100% helium-tested,

CE/IMQ/UL certified (depending on the version), and designed for compatibility

with A1 refrigerants. They operate within a temperature range of –35°C

to +65°C (–31°F ÷ +149°F) and support a maximum pressure of 30 bar (435

psi).

M.O.P.D. performance depends on the orifice size: 30

bar (Ø1.2 mm), 25 bar (Ø1.5 mm), 15 bar (Ø2.0 mm). Flow rate Kv: 0.05 /

0.08 / 0.12 m³/h.

Technical features:

COMPATIBLE A1 REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a

HFO e miscele HFO/HFC: R1234ze, R448A, R449A, R450A, R452A, R1234yf, R1233zdOur Neoprene compound gaskets have been designed and produced to be compatible with group A1 refrigerant gases (as defined in ASHRAE standard 34).However, in consideration of the infinite application variables (pressure, temperature and mixing percentages), an application check on the system is always required.

SECURE SEALING

The presence of a double O-ring on the tube ensures a perfect seal to the external environment, guaranteeing long-term protection and reliability.

BLOCK FLOW BALANCING

Each pilot mounted on the block is 100% flow-tested to ensure optimal flow balancing across all system sections.

DOUBLE THREAD MOUNTING

The block is equipped with a double thread mounting system, providing maximum installation flexibility and mechanical stability.

COIL INSULATION ENSURED

The coil insulation is guaranteed by the presence of upper and lower O-rings, shielding it from infiltration and thermal stress.

The Series

11000 solenoid valves are designed for small A1 refrigeration systems and

are available in a normally closed configuration, with yellow brass body

and copper pipes. They are offered in straight, L-shaped, or 2- and 3-valve

block versions, to ensure installation flexibility.

The inspectable

design allows for fast maintenance, and sealing is guaranteed by a PTFE

gasket and OLAB-certified neoprene O-ring.

The tube is

made of brass, and the 22 mm Ø10 coil, with H-class insulation

(180°C), includes a double O-ring and is fixed with a rotatable clip. The coil’s

upper and lower side is further insulated through dedicated O-rings,

ensuring durability and performance over time.

The Series 11000 valves are 100% helium-tested,

CE/IMQ/UL certified (depending on the version), and designed for compatibility

with A1 refrigerants. They operate within a temperature range of –35°C

to +65°C (–31°F ÷ +149°F) and support a maximum pressure of 30 bar (435

psi).

M.O.P.D. performance depends on the orifice size: 30

bar (Ø1.2 mm), 25 bar (Ø1.5 mm), 15 bar (Ø2.0 mm). Flow rate Kv: 0.05 /

0.08 / 0.12 m³/h.

Technical features:

COMPATIBLE A1 REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a

HFO e miscele HFO/HFC: R1234ze, R448A, R449A, R450A, R452A, R1234yf, R1233zdOur Neoprene compound gaskets have been designed and produced to be compatible with group A1 refrigerant gases (as defined in ASHRAE standard 34).However, in consideration of the infinite application variables (pressure, temperature and mixing percentages), an application check on the system is always required.

SECURE SEALING

The presence of a double O-ring on the tube ensures a perfect seal to the external environment, guaranteeing long-term protection and reliability.

BLOCK FLOW BALANCING

Each pilot mounted on the block is 100% flow-tested to ensure optimal flow balancing across all system sections.

DOUBLE THREAD MOUNTING

The block is equipped with a double thread mounting system, providing maximum installation flexibility and mechanical stability.

COIL INSULATION ENSURED

The coil insulation is guaranteed by the presence of upper and lower O-rings, shielding it from infiltration and thermal stress.