Notes:

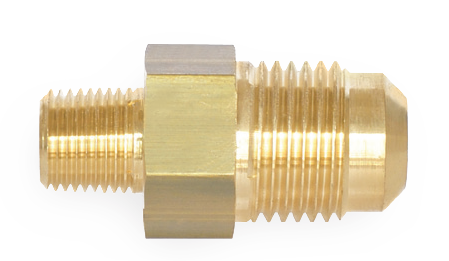

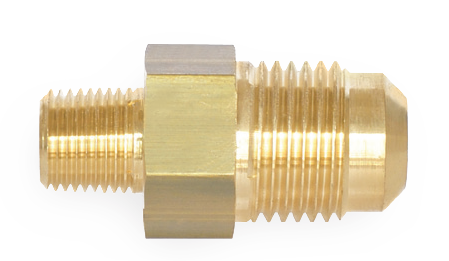

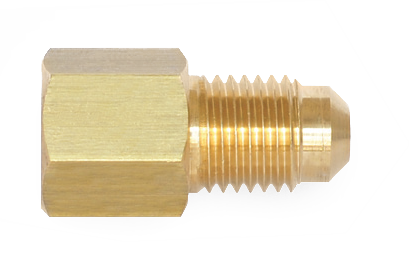

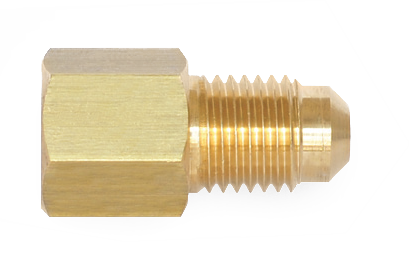

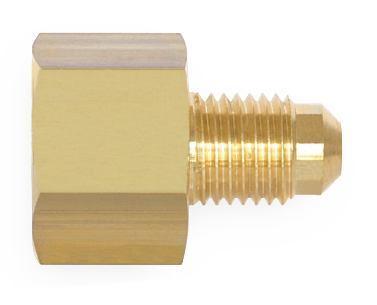

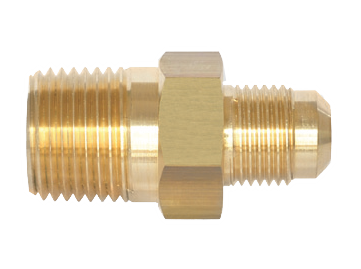

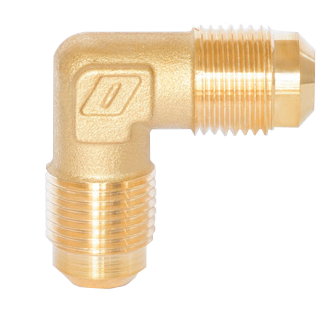

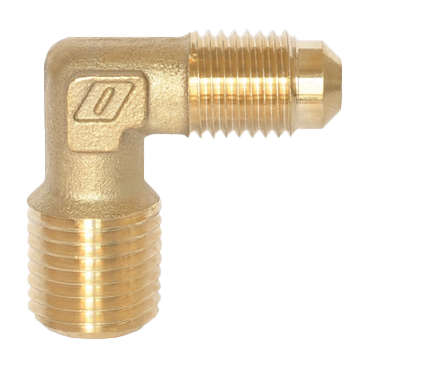

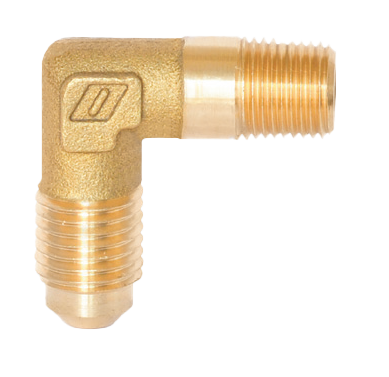

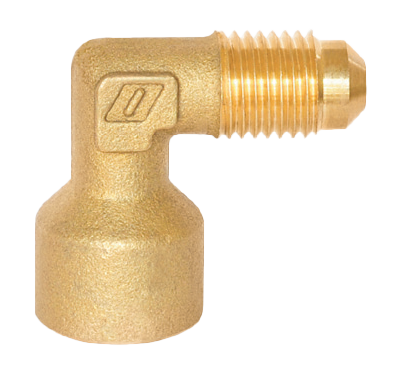

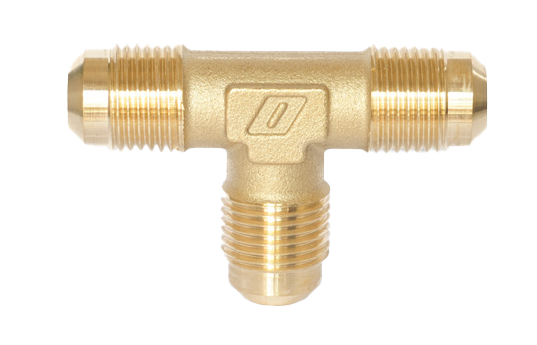

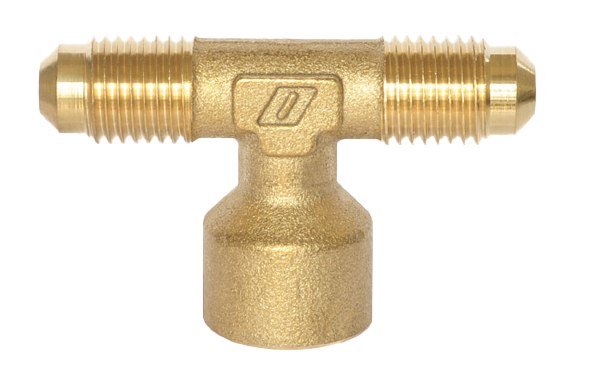

The Series

31000 includes access fittings and valve cores designed for professional

A1 refrigeration systems, offering reliability, mechanical precision, and

regulatory compliance.

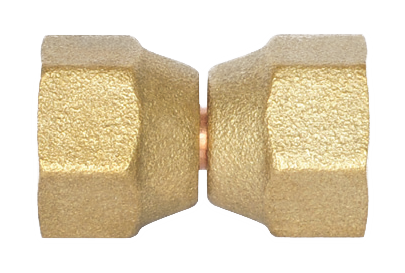

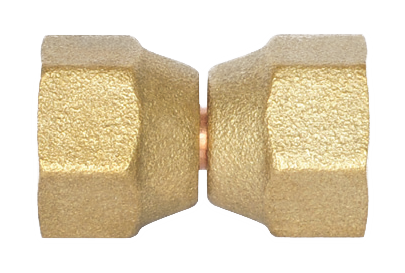

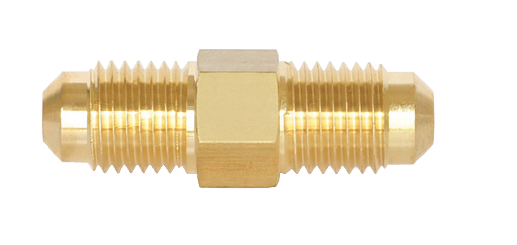

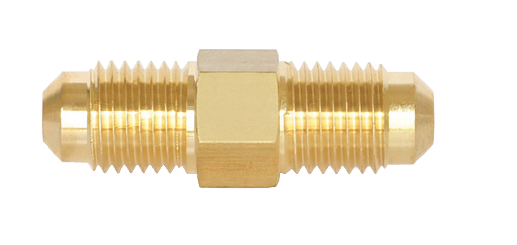

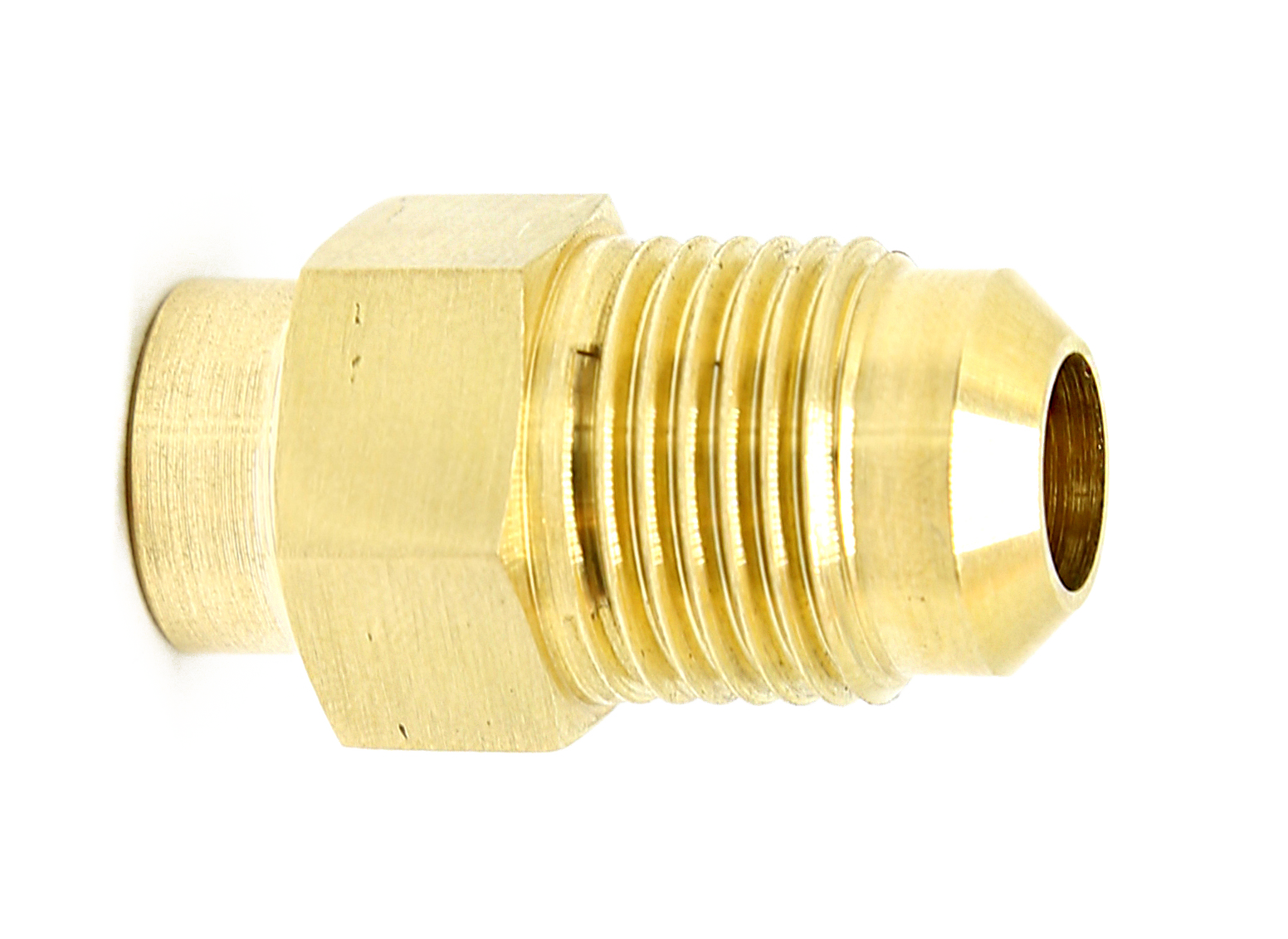

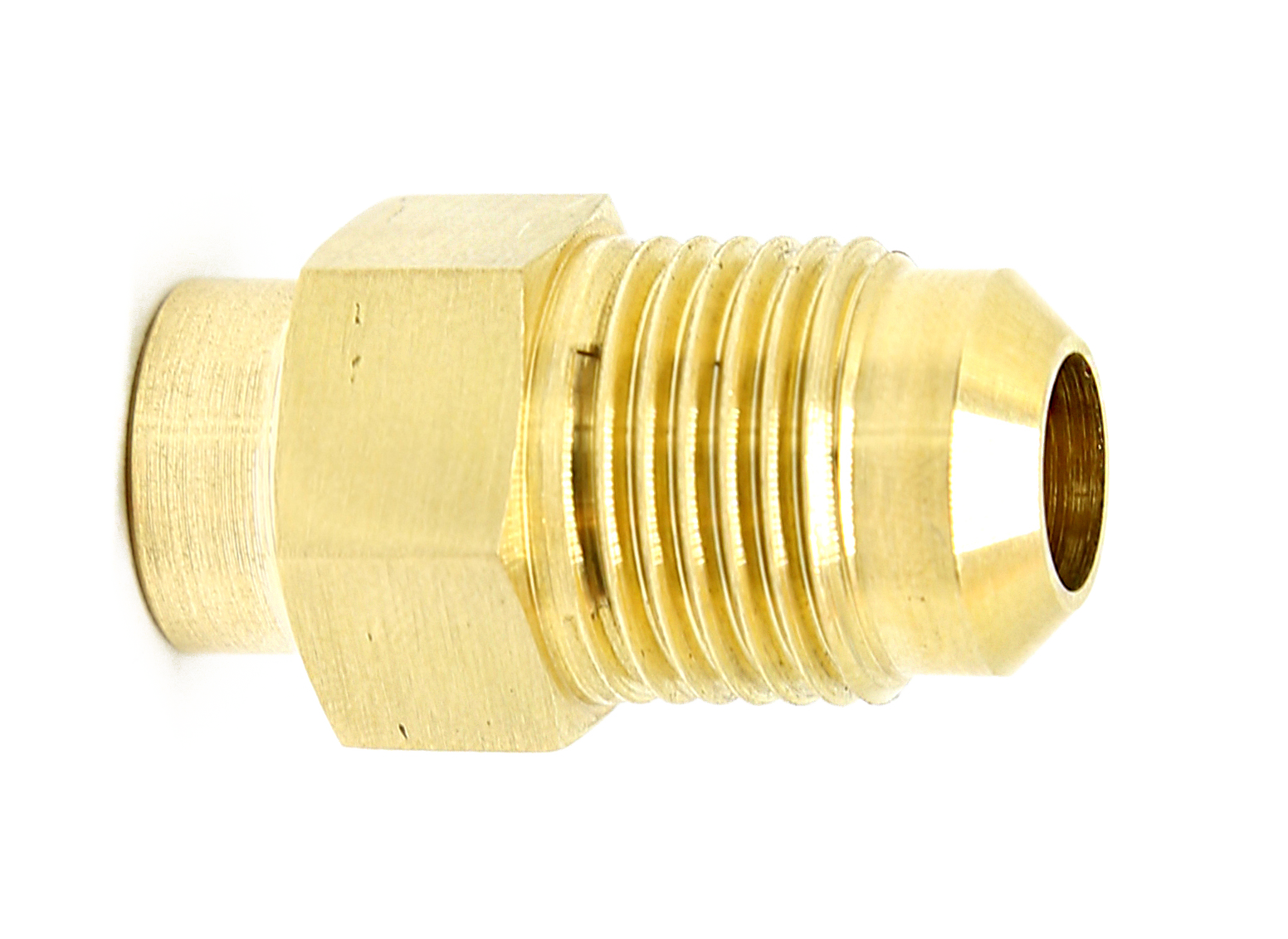

Manufactured from yellow brass EN 12164-CW614N or EN

12165-CW617N, components are available in both solid-bar machined

and hot-forged versions depending on the required size and performance.

These devices are not subject to PED Directive 2014/68/EU,

as they are considered pipe components. They are specifically intended

for air conditioning and refrigeration systems using Group II fluids

(non-toxic, non-flammable, non-explosive), including all refrigerants

classified A1 according to EN 378-1:2008, such as: R12 – R22 – R134a – R404A – R404C – R407C – R410A – R502 – R507, as well

as R30 – R123 – R141H – R245fa.

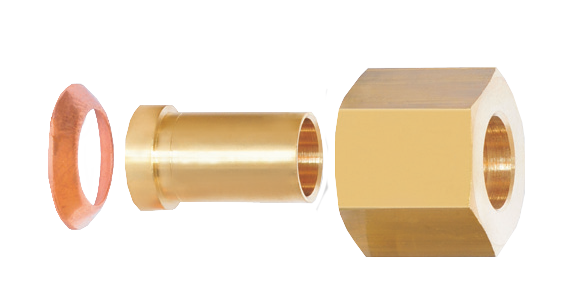

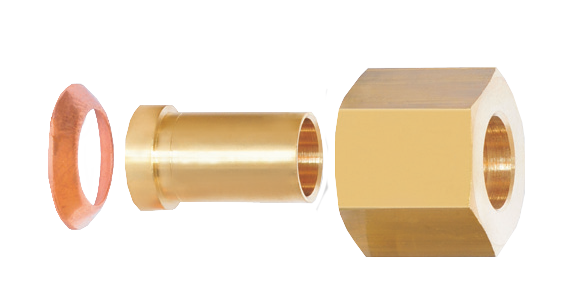

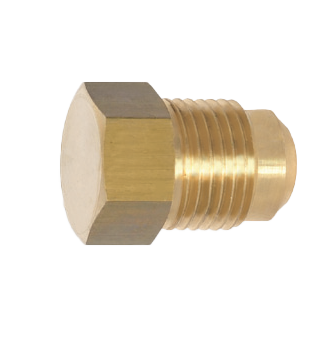

Sealing is achieved through a flared copper tube end,

mating with fittings from Series 31000, 31001, 31002, or 31003. Where flaring

is not permitted (per national regulations), the copper tube can be brazed

directly into the socket of the adapter, using a flared copper washer

(Series 31017/3) to ensure leak-free performance.

All components are built for high reliability:

• Nominal pressure (PS): 45 bar (653 psi)

• Hydrostatic test pressure: 65 bar, per PED (1.43 × PS)

• Burst pressure: ?135 bar, in accordance with EN 378-2:2008 (3 × PS)

Fittings are available with SAE or NPT threads,

compatible with most system layouts, and are CE certified.

Technical features:

COMPATIBLE A1 REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a

HFO e miscele HFO/HFC: R1234ze, R448A, R449A, R450A, R452A, R1234yf, R1233zdOur Neoprene compound gaskets have been designed and produced to be compatible with group A1 refrigerant gases (as defined in ASHRAE standard 34).However, in consideration of the infinite application variables (pressure, temperature and mixing percentages), an application check on the system is always required.

HIGHLY ROBUST

Designed to withstand the mechanical stress of professional refrigeration systems, they offer reliable performance even after repeated service cycles.

MADE FROM BAR AND HOT FORGED

Available in both solid bar machined and hot-forged versions, ensuring excellent structural density, dimensional stability, and suitability for high-pressure use.

RECOMMENDED TORQUE VALUES (SAE)

To ensure proper sealing and mechanical performance, apply the following torque settings:

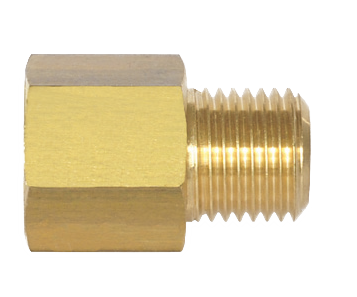

The Series

31000 includes access fittings and valve cores designed for professional

A1 refrigeration systems, offering reliability, mechanical precision, and

regulatory compliance.

Manufactured from yellow brass EN 12164-CW614N or EN

12165-CW617N, components are available in both solid-bar machined

and hot-forged versions depending on the required size and performance.

These devices are not subject to PED Directive 2014/68/EU,

as they are considered pipe components. They are specifically intended

for air conditioning and refrigeration systems using Group II fluids

(non-toxic, non-flammable, non-explosive), including all refrigerants

classified A1 according to EN 378-1:2008, such as: R12 – R22 – R134a – R404A – R404C – R407C – R410A – R502 – R507, as well

as R30 – R123 – R141H – R245fa.

Sealing is achieved through a flared copper tube end,

mating with fittings from Series 31000, 31001, 31002, or 31003. Where flaring

is not permitted (per national regulations), the copper tube can be brazed

directly into the socket of the adapter, using a flared copper washer

(Series 31017/3) to ensure leak-free performance.

All components are built for high reliability:

• Nominal pressure (PS): 45 bar (653 psi)

• Hydrostatic test pressure: 65 bar, per PED (1.43 × PS)

• Burst pressure: ?135 bar, in accordance with EN 378-2:2008 (3 × PS)

Fittings are available with SAE or NPT threads,

compatible with most system layouts, and are CE certified.

Technical features:

COMPATIBLE A1 REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a

HFO e miscele HFO/HFC: R1234ze, R448A, R449A, R450A, R452A, R1234yf, R1233zdOur Neoprene compound gaskets have been designed and produced to be compatible with group A1 refrigerant gases (as defined in ASHRAE standard 34).However, in consideration of the infinite application variables (pressure, temperature and mixing percentages), an application check on the system is always required.

HIGHLY ROBUST

Designed to withstand the mechanical stress of professional refrigeration systems, they offer reliable performance even after repeated service cycles.

MADE FROM BAR AND HOT FORGED

Available in both solid bar machined and hot-forged versions, ensuring excellent structural density, dimensional stability, and suitability for high-pressure use.

RECOMMENDED TORQUE VALUES (SAE)

To ensure proper sealing and mechanical performance, apply the following torque settings: