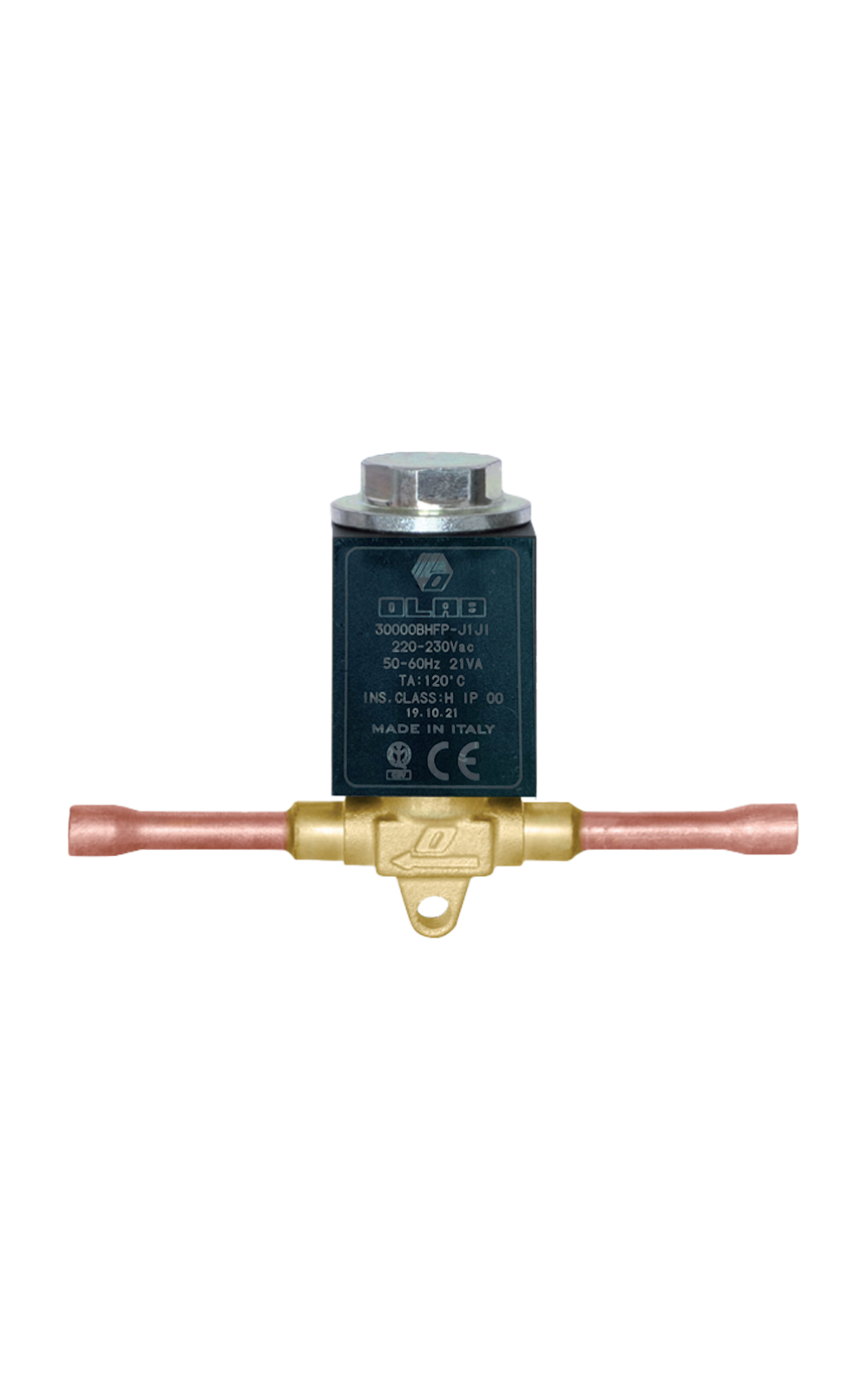

Ways: 2/2 N.C.

Notes:

The Series

35000 normally closed 2/2-way solenoid valves offer a compact, functional,

and cost-effective solution for A1 refrigeration systems in semi-professional

applications.

The yellow brass body, combined with copper tubes

and a PTFE sealing system, ensures chemical resistance and reliable

durability under moderate working conditions.

Designed as

a non-inspectable valve to simplify maintenance and reduce cost, the

Series 35000 features a 30 mm coil with ø14 mm bore, insulation class H,

capable of withstanding temperatures up to 180°C, providing stable

performance even in thermally demanding environments.

Thanks to

its space-saving design, it is ideal for installations where footprint

matters, while the use of standardized materials enables a highly

competitive quality-to-cost ratio. With a working pressure of up to 35

bar (507 psi) and an operating temperature range of –40°C to +120°C

(–40°F to +248°F), this solenoid valve meets the typical demands of

semi-professional refrigeration setups.

The valve

is CE certified, ensuring full compliance with European safety and

quality standards.

Technical features:

COMPATIBLE A1 REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a

HFO e miscele HFO/HFC: R1234ze, R448A, R449A, R450A, R452A, R1234yf, R1233zdOur Neoprene compound gaskets have been designed and produced to be compatible with group A1 refrigerant gases (as defined in ASHRAE standard 34).However, in consideration of the infinite application variables (pressure, temperature and mixing percentages), an application check on the system is always required.

The Series

35000 normally closed 2/2-way solenoid valves offer a compact, functional,

and cost-effective solution for A1 refrigeration systems in semi-professional

applications.

The yellow brass body, combined with copper tubes

and a PTFE sealing system, ensures chemical resistance and reliable

durability under moderate working conditions.

Designed as

a non-inspectable valve to simplify maintenance and reduce cost, the

Series 35000 features a 30 mm coil with ø14 mm bore, insulation class H,

capable of withstanding temperatures up to 180°C, providing stable

performance even in thermally demanding environments.

Thanks to

its space-saving design, it is ideal for installations where footprint

matters, while the use of standardized materials enables a highly

competitive quality-to-cost ratio. With a working pressure of up to 35

bar (507 psi) and an operating temperature range of –40°C to +120°C

(–40°F to +248°F), this solenoid valve meets the typical demands of

semi-professional refrigeration setups.

The valve

is CE certified, ensuring full compliance with European safety and

quality standards.

Technical features:

COMPATIBLE A1 REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a

HFO e miscele HFO/HFC: R1234ze, R448A, R449A, R450A, R452A, R1234yf, R1233zdOur Neoprene compound gaskets have been designed and produced to be compatible with group A1 refrigerant gases (as defined in ASHRAE standard 34).However, in consideration of the infinite application variables (pressure, temperature and mixing percentages), an application check on the system is always required.