Ways: 2/2 N.C.

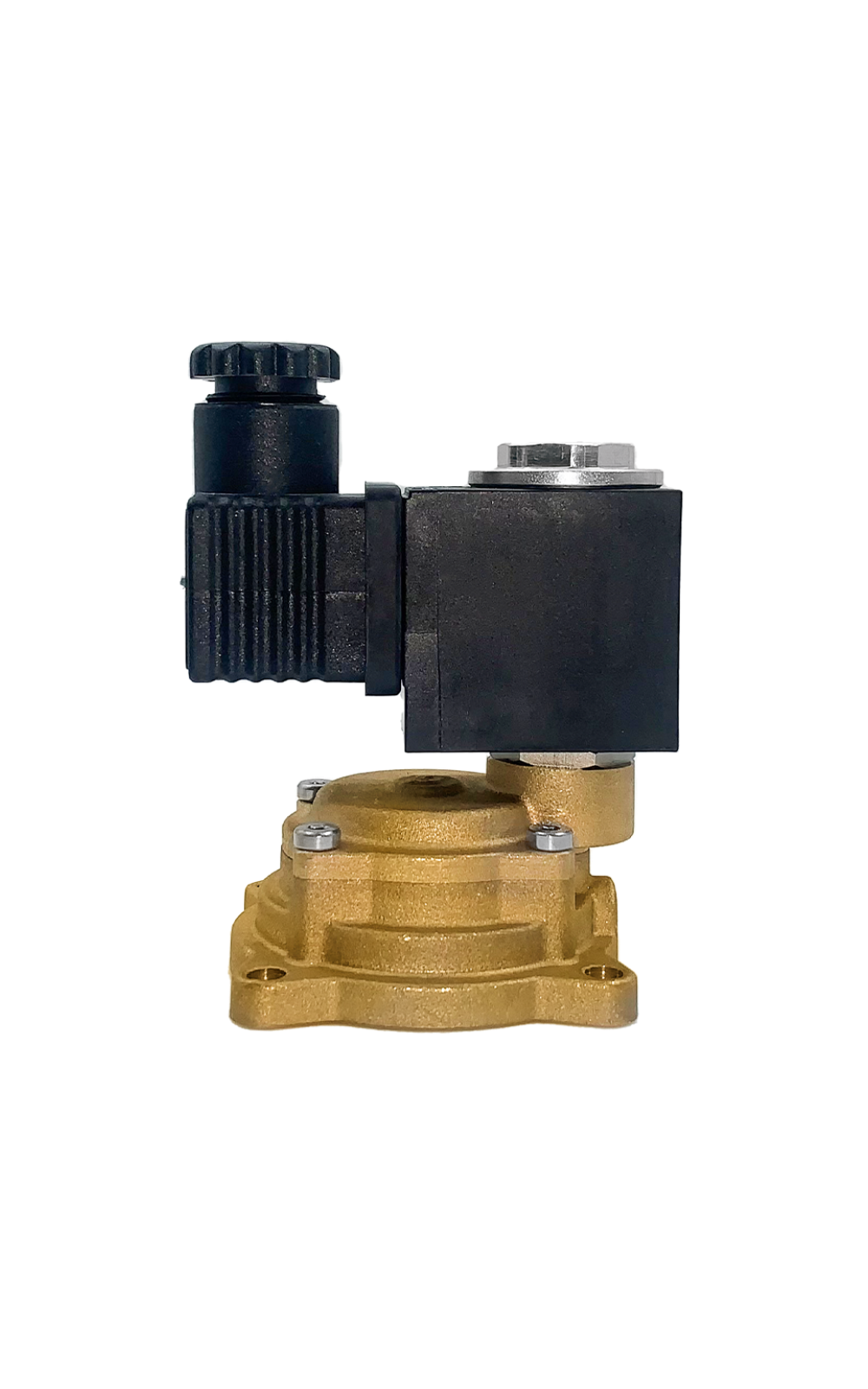

Notes: OLAB SOLUTION: THE FIRST INDIRECT ACTING FLANGE SOLENOID VALVE IN THE WORLD, A HI-QUALITY TECNOLOGY PRODUCT MADE BY OLAB

The 18001-00

Series is part of OLAB’s X-TREME PLUS range, specifically developed

for low-pressure Car Wash applications where modularity,

serviceability, and system continuity are critical.

It is a 2/2-way

normally closed solenoid valve, indirect-acting and equipped with a flanged

interface, perfectly suited for installation on K10081 multi-position

manifolds, where each valve has an independent inlet and outlet.

The yellow

brass body ensures structural integrity, while the AISI 304L stainless

steel sleeve with laser-welded fixed core provides high sealing

performance and long-lasting durability, even in wet or splash-prone

environments.

Sealing is achieved via NBR, EPDM, or OLAB-certified RBX

Hi-Performance gaskets, compatible with water, air, and cleaning agents.

Its inspectable design allows full internal access without

removing the valve from the hydraulic circuit.

The OLAB

8000BH coil (30 mm Ø14 mm), rated class H (up to 180°C / 356°F),

ensures electrical reliability at elevated temperatures. The assembly is fully

protected with an IP65 ingress rating, making it safe for harsh

industrial conditions. The valve is CE certified, ensuring full

compliance with European safety and hydraulic reliability standards for

low-pressure systems.

It operates

with a maximum static pressure (PS) of 20 bar (290 psi) and a working

differential pressure (OPD) range from 0.1 ÷ 0.4 bar (1.5 ÷ 6 psi) up to

12 ÷ 15 bar (174 ÷ 218 psi), with DN ranging from 11.5 to 26 mm

(0.45" ÷ 1.02").

As the core

valve used in the K10081 manifolds, the 18001-00 X-TREME PLUS Series is engineered to maximize

operational uptime, simplify servicing, and reduce maintenance

costs in automated Car Wash systems.

Technical features:

SOLENOID VALVE DESIGNED FOR LOW-PRESSURE CAR WASH SYSTEMS

Part of the X?TREME PLUS range, the 18001-00 Series is designed for use in multi-position manifolds like the K10081, where its indirect operation ensures reliability in modular systems operating at low pressures.

FLANGED CONNECTION FOR FAST AND PRECISE INSTALLATION

The flanged interface enables quick, stable, and precise mounting, ensuring proper alignment and time efficiency when integrated into Car Wash valve modules.

SERVICEABLE DESIGN WITH FULL INTERNAL ACCESS

The valve is fully inspectable, providing direct access to internal components without removing it from the system, reducing service complexity.

MINIMIZED MAINTENANCE COSTS AND SYSTEM DOWNTIME

Component accessibility and ease of replacement make it possible to lower maintenance costs and drastically cut system downtime, which is critical in automated wash facilities.

MAINTENANCE POSSIBLE WITHOUT SPECIALIZED PERSONNEL

Thanks to its user-friendly design, the 18001-00 Series allows for safe and fast service operations even by non-specialized operators, ensuring continuous and secure operation.

The 18001-00

Series is part of OLAB’s X-TREME PLUS range, specifically developed

for low-pressure Car Wash applications where modularity,

serviceability, and system continuity are critical.

It is a 2/2-way

normally closed solenoid valve, indirect-acting and equipped with a flanged

interface, perfectly suited for installation on K10081 multi-position

manifolds, where each valve has an independent inlet and outlet.

The yellow

brass body ensures structural integrity, while the AISI 304L stainless

steel sleeve with laser-welded fixed core provides high sealing

performance and long-lasting durability, even in wet or splash-prone

environments.

Sealing is achieved via NBR, EPDM, or OLAB-certified RBX

Hi-Performance gaskets, compatible with water, air, and cleaning agents.

Its inspectable design allows full internal access without

removing the valve from the hydraulic circuit.

The OLAB

8000BH coil (30 mm Ø14 mm), rated class H (up to 180°C / 356°F),

ensures electrical reliability at elevated temperatures. The assembly is fully

protected with an IP65 ingress rating, making it safe for harsh

industrial conditions. The valve is CE certified, ensuring full

compliance with European safety and hydraulic reliability standards for

low-pressure systems.

It operates

with a maximum static pressure (PS) of 20 bar (290 psi) and a working

differential pressure (OPD) range from 0.1 ÷ 0.4 bar (1.5 ÷ 6 psi) up to

12 ÷ 15 bar (174 ÷ 218 psi), with DN ranging from 11.5 to 26 mm

(0.45" ÷ 1.02").

As the core

valve used in the K10081 manifolds, the 18001-00 X-TREME PLUS Series is engineered to maximize

operational uptime, simplify servicing, and reduce maintenance

costs in automated Car Wash systems.

Technical features:

SOLENOID VALVE DESIGNED FOR LOW-PRESSURE CAR WASH SYSTEMS

Part of the X?TREME PLUS range, the 18001-00 Series is designed for use in multi-position manifolds like the K10081, where its indirect operation ensures reliability in modular systems operating at low pressures.

FLANGED CONNECTION FOR FAST AND PRECISE INSTALLATION

The flanged interface enables quick, stable, and precise mounting, ensuring proper alignment and time efficiency when integrated into Car Wash valve modules.

SERVICEABLE DESIGN WITH FULL INTERNAL ACCESS

The valve is fully inspectable, providing direct access to internal components without removing it from the system, reducing service complexity.

MINIMIZED MAINTENANCE COSTS AND SYSTEM DOWNTIME

Component accessibility and ease of replacement make it possible to lower maintenance costs and drastically cut system downtime, which is critical in automated wash facilities.

MAINTENANCE POSSIBLE WITHOUT SPECIALIZED PERSONNEL

Thanks to its user-friendly design, the 18001-00 Series allows for safe and fast service operations even by non-specialized operators, ensuring continuous and secure operation.