Ways: 2/2 N.C.

Notes:

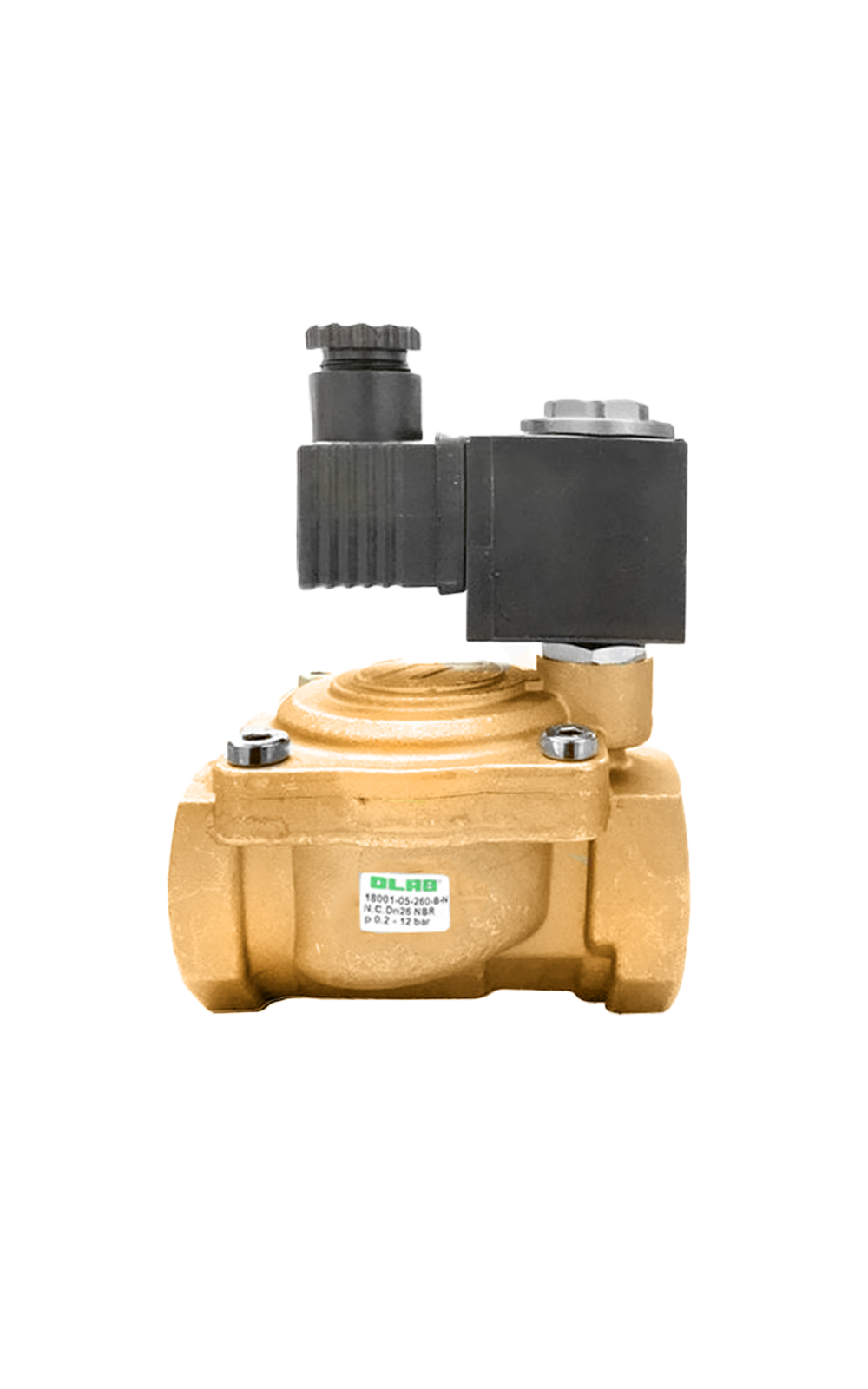

The 18001

Series belongs to the X-TREME PLUS range, specifically designed by

OLAB for low-pressure Car Wash systems requiring high reliability,

consistent performance, and easy serviceability.

These are 2/2-way

normally closed indirect-acting valves, ideal for handling high

differential pressures even with large internal orifices.

The valve

body is made of CW510L-OT57 brass, and the AISI 304 stainless steel

sleeve, equipped with a laser-welded fixed core, ensures long-term

sealing performance under severe mechanical and thermal stress. Sealing

gaskets are available in NBR, EPDM, and OLAB-certified RBX

Hi-Performance, guaranteeing compatibility with water, detergents, and

compressed air.

The core of

the electromechanical system features the 30 mm Ø14 OLAB 8000BH coil,

rated Class H (up to 180 °C / 356 °F), designed to withstand continuous

cycles, vibration, and thermal peaks. The inspectable architecture

enables quick and safe maintenance without the need to remove the valve

from the system.

The 18001

Series is CE certified and rated IP65, making it fully compliant

with European directives for electrical safety and industrial durability in

low-pressure fluid systems.

Technical features:

DESIGNED FOR LOW-PRESSURE CAR WASH SYSTEMS

Part of the X?TREME PLUS range, engineered for automatic wash systems operating under moderate pressure.

HIGH DIFFERENTIAL PRESSURE CONTROL EVEN WITH LARGE ORIFICES

The indirect-acting system handles significant pressure differences while maintaining stable and smooth operation through wide internal passages.

REDUCED POWER CONSUMPTION, MAXIMUM EFFICIENCY

Thanks to its pilot-operated structure, the valve ensures efficient actuation under pressure with low solenoid power requirements.

OLAB 8000BH COIL CLASS H FOR HEAVY-DUTY CYCLES

The 30 mm (Ø14 mm) coil is built for continuous duty, withstanding heat, vibration and high-frequency cycling without loss of performance.

INSPECTABLE DESIGN FOR EASY MAINTENANCE

The fully serviceable architecture allows internal access without removing the valve from the line, reducing downtime and simplifying technical interventions.

The 18001

Series belongs to the X-TREME PLUS range, specifically designed by

OLAB for low-pressure Car Wash systems requiring high reliability,

consistent performance, and easy serviceability.

These are 2/2-way

normally closed indirect-acting valves, ideal for handling high

differential pressures even with large internal orifices.

The valve

body is made of CW510L-OT57 brass, and the AISI 304 stainless steel

sleeve, equipped with a laser-welded fixed core, ensures long-term

sealing performance under severe mechanical and thermal stress. Sealing

gaskets are available in NBR, EPDM, and OLAB-certified RBX

Hi-Performance, guaranteeing compatibility with water, detergents, and

compressed air.

The core of

the electromechanical system features the 30 mm Ø14 OLAB 8000BH coil,

rated Class H (up to 180 °C / 356 °F), designed to withstand continuous

cycles, vibration, and thermal peaks. The inspectable architecture

enables quick and safe maintenance without the need to remove the valve

from the system.

The 18001

Series is CE certified and rated IP65, making it fully compliant

with European directives for electrical safety and industrial durability in

low-pressure fluid systems.

Technical features:

DESIGNED FOR LOW-PRESSURE CAR WASH SYSTEMS

Part of the X?TREME PLUS range, engineered for automatic wash systems operating under moderate pressure.

HIGH DIFFERENTIAL PRESSURE CONTROL EVEN WITH LARGE ORIFICES

The indirect-acting system handles significant pressure differences while maintaining stable and smooth operation through wide internal passages.

REDUCED POWER CONSUMPTION, MAXIMUM EFFICIENCY

Thanks to its pilot-operated structure, the valve ensures efficient actuation under pressure with low solenoid power requirements.

OLAB 8000BH COIL CLASS H FOR HEAVY-DUTY CYCLES

The 30 mm (Ø14 mm) coil is built for continuous duty, withstanding heat, vibration and high-frequency cycling without loss of performance.

INSPECTABLE DESIGN FOR EASY MAINTENANCE

The fully serviceable architecture allows internal access without removing the valve from the line, reducing downtime and simplifying technical interventions.