Notes: OLAB

SOLUTION: EXTREMELY PRATICAL SIMPLE AND SAFE SYSTEM MAINTENANCE

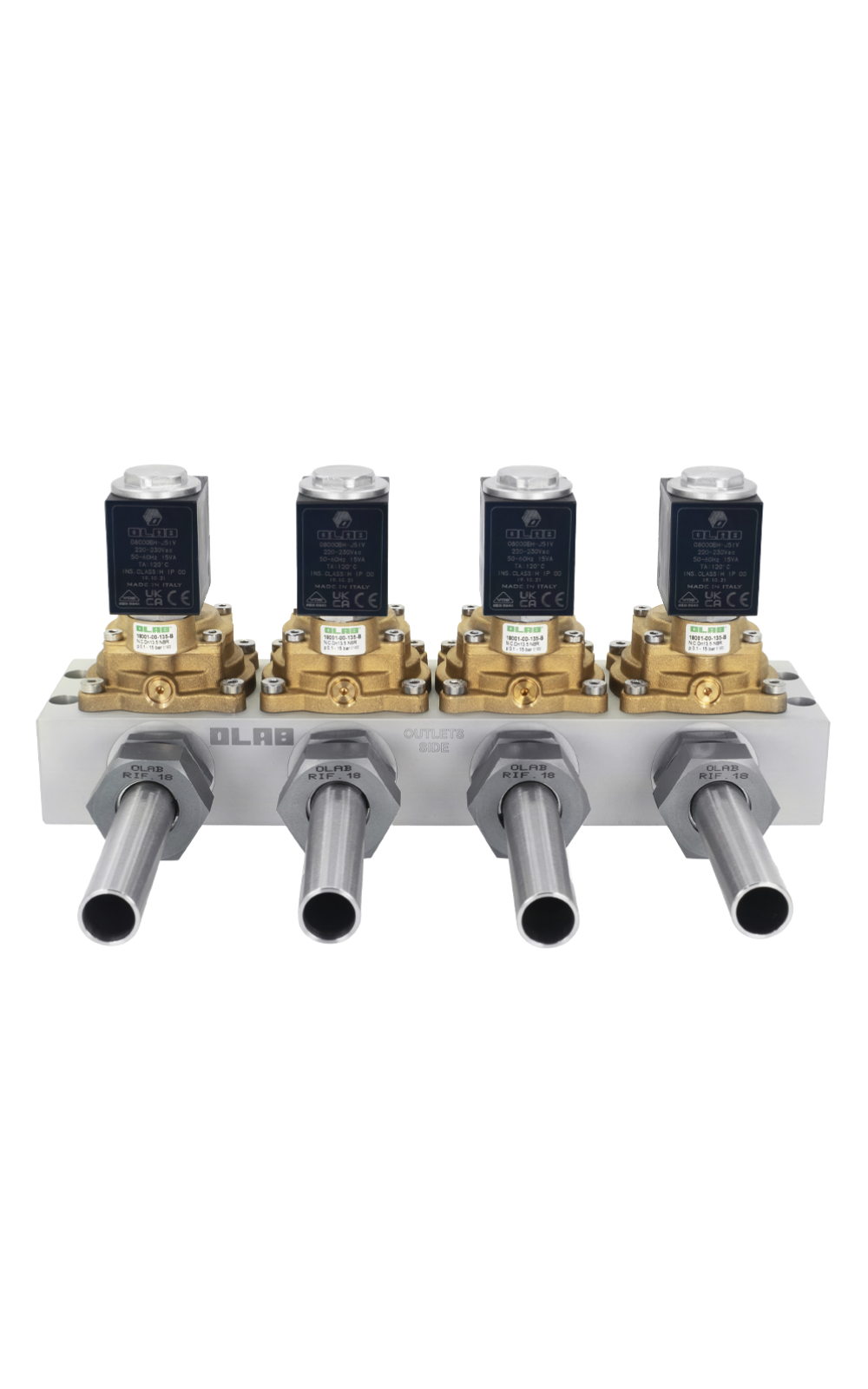

The Series

K09726 includes anodized aluminum manifolds specifically designed

for the parallel installation of multiple solenoid valves, particularly the OLAB

Series 18001-00 flanged valves, allowing for a compact, organized, and

fully modular configuration. The design accommodates 2 to 4 independent

ports, enabling efficient management of multiple lines within a single

system and optimizing flow distribution.

Each

manifold features female cylindrical gas threads on both inlet and outlet

ports, with a machined external surface to ensure perfect sealing

when used with cylindrical male fittings equipped with O-Rings.

This

technical solution guarantees a secure, durable, and leak-free connection over

time.

The

interface with the valves has been carefully engineered for fast and easy

assembly, requiring no additional machining or adaptors. Thanks to the front

access and the well-organized layout of connections, targeted interventions

can be carried out on each port independently, with minimal impact on the rest

of the system. This design ensures that the manifold remains easy to service

even during operation.

The system

has been conceived to reduce maintenance costs, thanks to its mechanical

simplicity and seamless compatibility with OLAB solenoid valves. In

case of service, individual valves can be replaced without removing the

entire block, resulting in minimal system downtime and maintaining continuous

operation even during technical interventions. Furthermore, the intuitive

layout and direct accessibility allow for safe and efficient maintenance by

non-specialized personnel.

The Series

K09726 embodies the spirit of the OLAB Solution: a system engineered

for extremely practical, simple, and safe system maintenance, fully

aligned with the highest standards of professional reliability.

The

manifolds support a maximum operating pressure of 25 bar (362 psi) and

are compatible with EPDM, RBX, or NBR seals, offering temperature ranges

of –20°C to +90°C (–4°F to +194°F) for EPDM, –30°C to +145°C (–22°F

to +293°F) for RBX, and –15°C to +150°C (+5°F to +302°F) for NBR.

Available with female threaded ports in 3/8", 1/2", 3/4", and

1", the product is CE, UL certified, ensuring full compliance with

international quality and safety standards.

Technical features:

FROM 2 TO 4 INDEPENDENT PORTS

Available in two to four-port configurations, the manifold allows for the parallel installation of multiple solenoid valves on separate lines, optimizing flow management and system modularity.

DESIGNED FOR EASY ASSEMBLY

Every structural detail has been engineered to simplify integration with 18001-00 Series solenoid valves, enabling fast, intuitive installation with no additional machining required.

QUICK SYSTEM MAINTENANCE

Front access and an orderly layout of the connections allow immediate intervention on each individual port, minimizing the impact on adjacent lines.

DESIGNED TO REDUCE SERVICE COSTS

Thanks to its mechanical simplicity and direct compatibility with cylindrical male fittings with O-Ring, the manifold reduces the time and labor needed for any maintenance activity.

MINIMIZED SYSTEM DOWNTIME

The quick-connect design and the ability to replace individual valves without removing the entire assembly ensure that the system remains operational even during maintenance.

MAINTENANCE DOES NOT REQUIRE SPECIALIZED PERSONNEL

The system is designed to be operated safely even by non-technical staff, thanks to its extreme practicality and clear, accessible connections.

The Series

K09726 includes anodized aluminum manifolds specifically designed

for the parallel installation of multiple solenoid valves, particularly the OLAB

Series 18001-00 flanged valves, allowing for a compact, organized, and

fully modular configuration. The design accommodates 2 to 4 independent

ports, enabling efficient management of multiple lines within a single

system and optimizing flow distribution.

Each

manifold features female cylindrical gas threads on both inlet and outlet

ports, with a machined external surface to ensure perfect sealing

when used with cylindrical male fittings equipped with O-Rings.

This

technical solution guarantees a secure, durable, and leak-free connection over

time.

The

interface with the valves has been carefully engineered for fast and easy

assembly, requiring no additional machining or adaptors. Thanks to the front

access and the well-organized layout of connections, targeted interventions

can be carried out on each port independently, with minimal impact on the rest

of the system. This design ensures that the manifold remains easy to service

even during operation.

The system

has been conceived to reduce maintenance costs, thanks to its mechanical

simplicity and seamless compatibility with OLAB solenoid valves. In

case of service, individual valves can be replaced without removing the

entire block, resulting in minimal system downtime and maintaining continuous

operation even during technical interventions. Furthermore, the intuitive

layout and direct accessibility allow for safe and efficient maintenance by

non-specialized personnel.

The Series

K09726 embodies the spirit of the OLAB Solution: a system engineered

for extremely practical, simple, and safe system maintenance, fully

aligned with the highest standards of professional reliability.

The

manifolds support a maximum operating pressure of 25 bar (362 psi) and

are compatible with EPDM, RBX, or NBR seals, offering temperature ranges

of –20°C to +90°C (–4°F to +194°F) for EPDM, –30°C to +145°C (–22°F

to +293°F) for RBX, and –15°C to +150°C (+5°F to +302°F) for NBR.

Available with female threaded ports in 3/8", 1/2", 3/4", and

1", the product is CE, UL certified, ensuring full compliance with

international quality and safety standards.

Technical features:

FROM 2 TO 4 INDEPENDENT PORTS

Available in two to four-port configurations, the manifold allows for the parallel installation of multiple solenoid valves on separate lines, optimizing flow management and system modularity.

DESIGNED FOR EASY ASSEMBLY

Every structural detail has been engineered to simplify integration with 18001-00 Series solenoid valves, enabling fast, intuitive installation with no additional machining required.

QUICK SYSTEM MAINTENANCE

Front access and an orderly layout of the connections allow immediate intervention on each individual port, minimizing the impact on adjacent lines.

DESIGNED TO REDUCE SERVICE COSTS

Thanks to its mechanical simplicity and direct compatibility with cylindrical male fittings with O-Ring, the manifold reduces the time and labor needed for any maintenance activity.

MINIMIZED SYSTEM DOWNTIME

The quick-connect design and the ability to replace individual valves without removing the entire assembly ensure that the system remains operational even during maintenance.

MAINTENANCE DOES NOT REQUIRE SPECIALIZED PERSONNEL

The system is designed to be operated safely even by non-technical staff, thanks to its extreme practicality and clear, accessible connections.