Ways: 2/2

Notes:

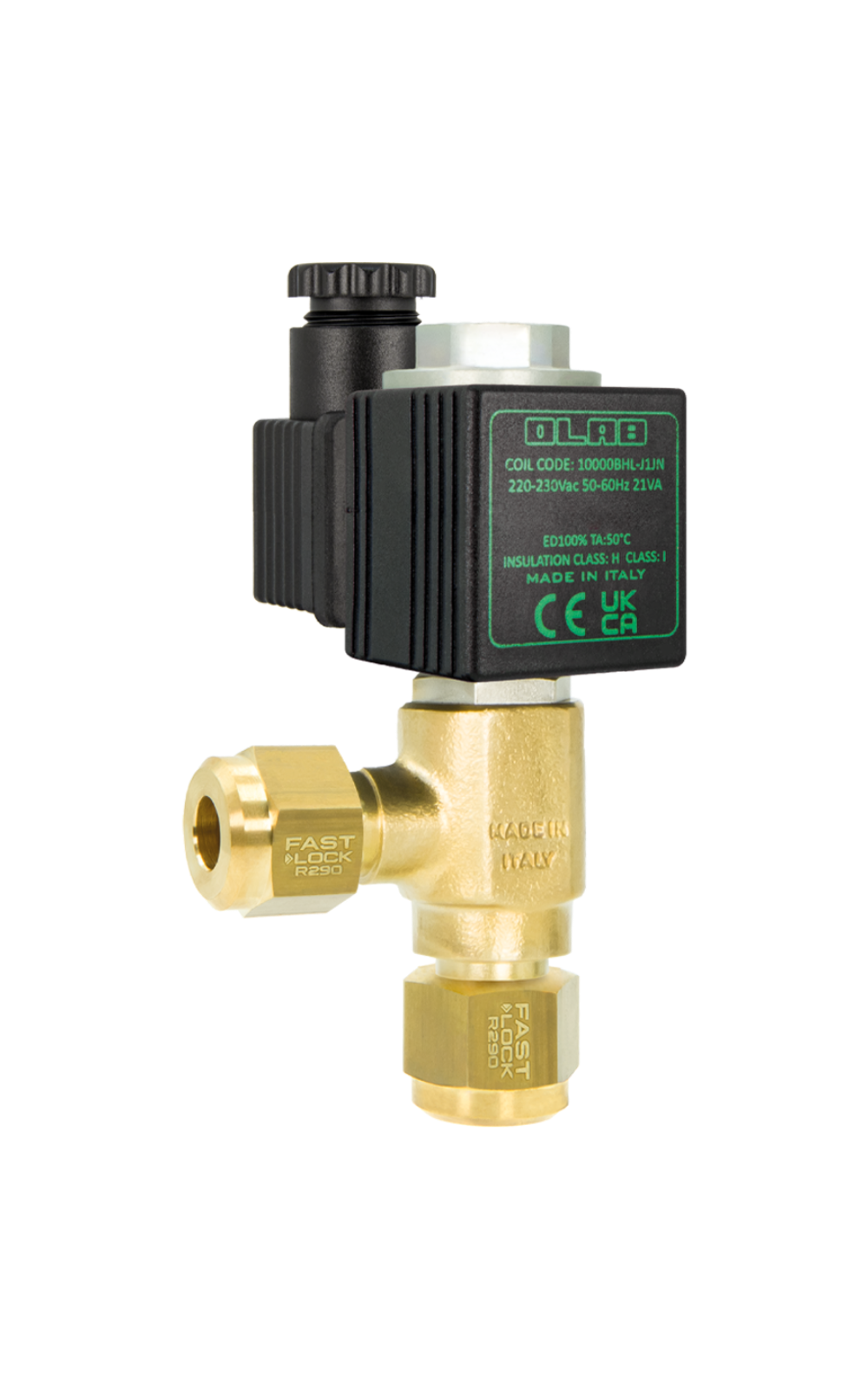

The EXPANSIONTECH

Series (44220-2) is a normally closed 2/2-way solenoid expansion valve

developed by OLAB for professional A3–A2L refrigeration systems. Equipped with Fast

Lock A3-A2L connections, the valve eliminates the need for soldering,

minimizing leakage risks and simplifying assembly.

Its PTFE sealing system

combined with HNBR O-Rings 100% PFAS-FREE certified by OLAB ensures

absolute tightness even under thermal and mechanical stress, while the AISI

304 stainless steel sleeve, laser-welded in OLAB’s dedicated facility,

guarantees durability and long-lasting performance.

The interchangeable

stainless steel DN insert is removable and reusable, allowing full

compatibility with the complete range of DN sizes. An internal

stainless steel filter, fully inspectable, protects the circuit from even

the smallest impurities, maintaining system cleanliness.

The 36 mm Class

H (180°C) coil with double O-Ring provides outstanding insulation

and thermal resistance, while the UL-certified IP67 protection rating

ensures complete sealing from dust and temporary water immersion.

Each unit is individually tested with pure helium

using advanced OLAB equipment. The laser marking of date and serial

number certifies successful testing and provides lifetime traceability of

performance data. The valve is rated for 52 bar (754 psi) and

operates within a thermal range of –40°C to +100°C (–40°F ÷ +212°F). It is part of the OLAB LOW-PFAS IMPACT COMPONENTS

product line.

Technical features:

COMPATIBLE A3–A2L REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a (up to +125°C / 257°F).

HFO and HFO/HFC blends: R1234ze, R448A, R449A, R450A, R452A, R1234yf.

HC: R290, R600, R600a.

Products equipped with HNBR seals must not be installed on systems using HCFCs (R22) or any refrigerants mixed with mineral oils or alkylbenzene lubricants.

Our HNBR compound seals have been specifically designed and manufactured for compatibility with A3 and A2L refrigerant gases (as defined in ASHRAE Standard 34). However, due to the countless variables involved in real-world applications—such as pressure, temperature, and mixing ratios—an application-specific validation on the system is always required.

NO WELDING, NO LEAKAGE

Thanks to the Fast Lock A3-A2L connections.

DOUBLE HNBR O-RING, 100% PFAS-FREE, OLAB-CERTIFIED

Guaranteed sealing between both the body and the nozzle, and the body and the tube.

MAXIMUM COIL INSULATION

Achieved with the addition of two O-Rings, one on top and one below.

IP67

Engineered for maximum moisture protection and long-lasting durability.

INTERCHANGEABLE STAINLESS STEEL DN INSERT

Removable and reinstallable, compatible with the entire range of available DN sizes.

MAXIMUM CLEANLINESS

Thanks to the integrated (inspectable) filter, which blocks even the smallest impurities from entering the circuit.

AISI 304 STAINLESS STEEL SLEEVE

Laser-welded in-house at OLAB with a dedicated system, ensuring perfect welds for long-lasting performance and durability.

100% HELIUM TESTED

Each valve is individually tested with pure helium in a dedicated facility. Laser-engraved date and serial number ensure lifetime traceability of recorded performance data.

The EXPANSIONTECH

Series (44220-2) is a normally closed 2/2-way solenoid expansion valve

developed by OLAB for professional A3–A2L refrigeration systems. Equipped with Fast

Lock A3-A2L connections, the valve eliminates the need for soldering,

minimizing leakage risks and simplifying assembly.

Its PTFE sealing system

combined with HNBR O-Rings 100% PFAS-FREE certified by OLAB ensures

absolute tightness even under thermal and mechanical stress, while the AISI

304 stainless steel sleeve, laser-welded in OLAB’s dedicated facility,

guarantees durability and long-lasting performance.

The interchangeable

stainless steel DN insert is removable and reusable, allowing full

compatibility with the complete range of DN sizes. An internal

stainless steel filter, fully inspectable, protects the circuit from even

the smallest impurities, maintaining system cleanliness.

The 36 mm Class

H (180°C) coil with double O-Ring provides outstanding insulation

and thermal resistance, while the UL-certified IP67 protection rating

ensures complete sealing from dust and temporary water immersion.

Each unit is individually tested with pure helium

using advanced OLAB equipment. The laser marking of date and serial

number certifies successful testing and provides lifetime traceability of

performance data. The valve is rated for 52 bar (754 psi) and

operates within a thermal range of –40°C to +100°C (–40°F ÷ +212°F). It is part of the OLAB LOW-PFAS IMPACT COMPONENTS

product line.

Technical features:

COMPATIBLE A3–A2L REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a (up to +125°C / 257°F).

HFO and HFO/HFC blends: R1234ze, R448A, R449A, R450A, R452A, R1234yf.

HC: R290, R600, R600a.

Products equipped with HNBR seals must not be installed on systems using HCFCs (R22) or any refrigerants mixed with mineral oils or alkylbenzene lubricants.

Our HNBR compound seals have been specifically designed and manufactured for compatibility with A3 and A2L refrigerant gases (as defined in ASHRAE Standard 34). However, due to the countless variables involved in real-world applications—such as pressure, temperature, and mixing ratios—an application-specific validation on the system is always required.

NO WELDING, NO LEAKAGE

Thanks to the Fast Lock A3-A2L connections.

DOUBLE HNBR O-RING, 100% PFAS-FREE, OLAB-CERTIFIED

Guaranteed sealing between both the body and the nozzle, and the body and the tube.

MAXIMUM COIL INSULATION

Achieved with the addition of two O-Rings, one on top and one below.

IP67

Engineered for maximum moisture protection and long-lasting durability.

INTERCHANGEABLE STAINLESS STEEL DN INSERT

Removable and reinstallable, compatible with the entire range of available DN sizes.

MAXIMUM CLEANLINESS

Thanks to the integrated (inspectable) filter, which blocks even the smallest impurities from entering the circuit.

AISI 304 STAINLESS STEEL SLEEVE

Laser-welded in-house at OLAB with a dedicated system, ensuring perfect welds for long-lasting performance and durability.

100% HELIUM TESTED

Each valve is individually tested with pure helium in a dedicated facility. Laser-engraved date and serial number ensure lifetime traceability of recorded performance data.