Category: A3-A2L SPECIALIST

Ways: 2/2

Notes:

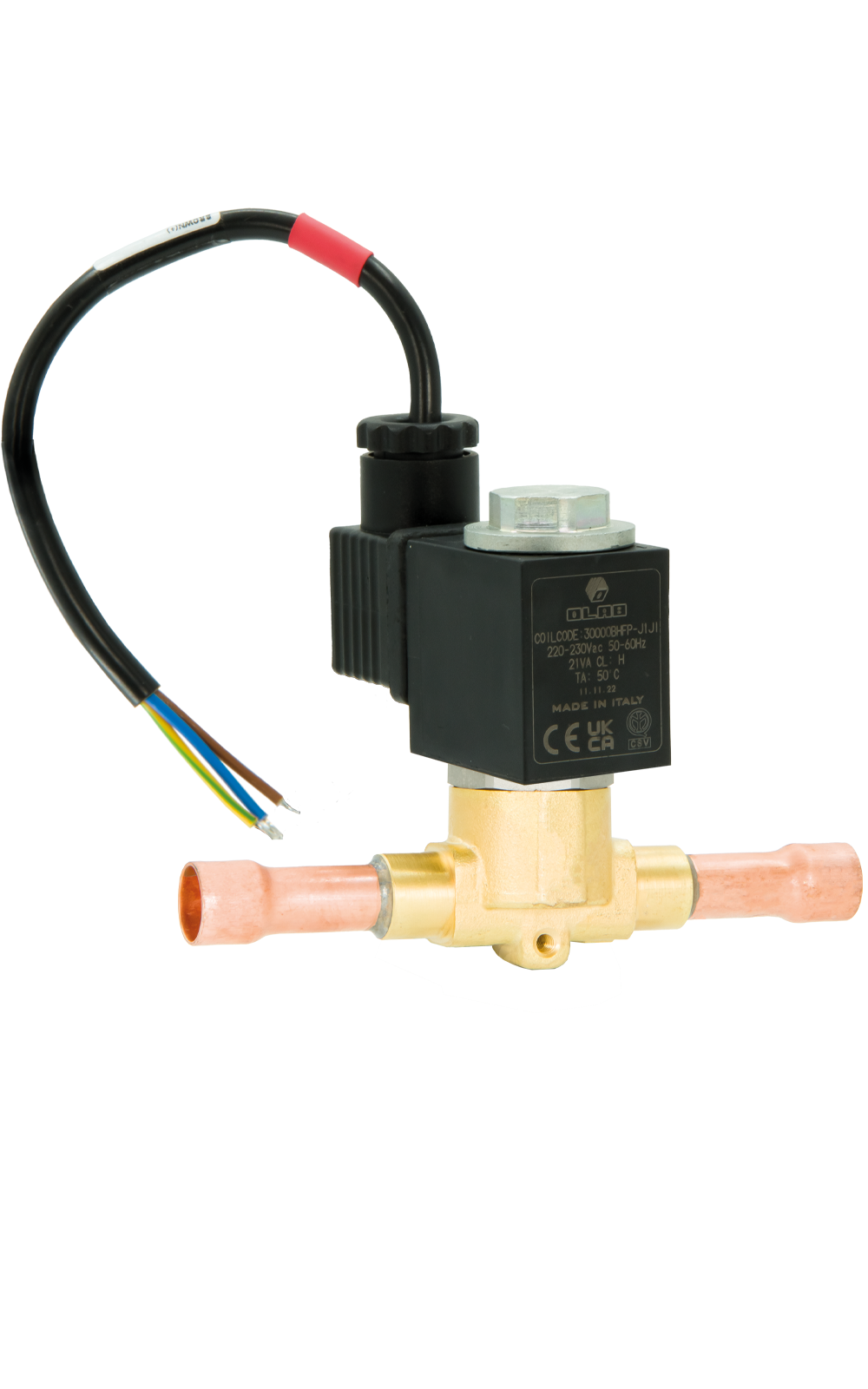

The Series

30500-2 is OLAB’s 2/2-way normally open solenoid valve, specifically

developed for use in professional A3–A2L refrigeration systems. Fully inspectable

and engineered to deliver long-lasting reliability and sealing integrity,

it combines a PTFE seal with a HNBR O-Ring, 100% PFAS-FREE and

OLAB-certified, ensuring airtight performance even under high

mechanical or thermal stress.

The sleeve

is machined from solid AISI 303 stainless steel bar, providing increased

wall thickness, greater mechanical strength, and long-term

durability when compared to traditional thin-sheet metal designs. The valve

body, made from yellow brass, ensures dependable operation even

under extreme working conditions.

This valve

features a 36 mm coil with 14 mm bore, Class H thermal

insulation (180 °C), and a double O-Ring seal, offering excellent

thermal resistance and effective electrical insulation.

The complete

unit is IP67 rated and certified to CE, UL 207 and UL 429, ensuring

full protection against dust ingress and temporary water immersion.

Each unit

undergoes individual 100% helium testing in OLAB’s advanced facility.

The laser-marked date and serial number confirm the test has been passed

and enable lifetime traceability of the recorded performance data.

The Series

30500-2 is rated for operation up to 52 bar (753 psi) and a

temperature range of –40 °C to +130 °C (–40 °F to +266 °F). It is part

of the OLAB LOW-PFAS IMPACT COMPONENTS range, delivering high technical

performance with a reduced environmental footprint.

Technical features:

REFRIGERANT GASES A1-A2L-A3 COMPATIBLE

HFC, HFO and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a (up to +125°C / 257°F).

HFO and HFO/HFC blends: R1234ze, R448A, R449A, R450A, R452A, R1234yf.

HC: R290, R600, R600a.

Products with HNBR gaskets cannot be installed on systems using HCFC (R22) or other coolants containing mineral oils or alkyl-benzene.

EXCEPTIONALLY ROBUST

The sleeve, made from AISI 303 stainless steel and machined from solid bar, features a greater wall thickness than traditional sleeves made from thin metal sheets, ensuring superior mechanical strength and long-term durability.

IP67 CERTIFIED SAFETY

Rated IP67 and UL certified, the valve guarantees complete protection against dust ingress and temporary water immersion, in compliance with international standards.

CLASS H Ø36 MM COIL WITH DOUBLE O-RING SEALING

The 36 mm coil, thermally insulated in Class H (180°C), is equipped with dual O-Ring sealing, ensuring high resistance to temperature and excellent sealing integrity.

100% HELIUM TESTED

Each unit is individually tested in a state-of-the-art helium facility. Date and serial number are engraved to certify compliance and allow full traceability of recorded performance data.

The Series

30500-2 is OLAB’s 2/2-way normally open solenoid valve, specifically

developed for use in professional A3–A2L refrigeration systems. Fully inspectable

and engineered to deliver long-lasting reliability and sealing integrity,

it combines a PTFE seal with a HNBR O-Ring, 100% PFAS-FREE and

OLAB-certified, ensuring airtight performance even under high

mechanical or thermal stress.

The sleeve

is machined from solid AISI 303 stainless steel bar, providing increased

wall thickness, greater mechanical strength, and long-term

durability when compared to traditional thin-sheet metal designs. The valve

body, made from yellow brass, ensures dependable operation even

under extreme working conditions.

This valve

features a 36 mm coil with 14 mm bore, Class H thermal

insulation (180 °C), and a double O-Ring seal, offering excellent

thermal resistance and effective electrical insulation.

The complete

unit is IP67 rated and certified to CE, UL 207 and UL 429, ensuring

full protection against dust ingress and temporary water immersion.

Each unit

undergoes individual 100% helium testing in OLAB’s advanced facility.

The laser-marked date and serial number confirm the test has been passed

and enable lifetime traceability of the recorded performance data.

The Series

30500-2 is rated for operation up to 52 bar (753 psi) and a

temperature range of –40 °C to +130 °C (–40 °F to +266 °F). It is part

of the OLAB LOW-PFAS IMPACT COMPONENTS range, delivering high technical

performance with a reduced environmental footprint.

Technical features:

REFRIGERANT GASES A1-A2L-A3 COMPATIBLE

HFC, HFO and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a (up to +125°C / 257°F).

HFO and HFO/HFC blends: R1234ze, R448A, R449A, R450A, R452A, R1234yf.

HC: R290, R600, R600a.

Products with HNBR gaskets cannot be installed on systems using HCFC (R22) or other coolants containing mineral oils or alkyl-benzene.

EXCEPTIONALLY ROBUST

The sleeve, made from AISI 303 stainless steel and machined from solid bar, features a greater wall thickness than traditional sleeves made from thin metal sheets, ensuring superior mechanical strength and long-term durability.

IP67 CERTIFIED SAFETY

Rated IP67 and UL certified, the valve guarantees complete protection against dust ingress and temporary water immersion, in compliance with international standards.

CLASS H Ø36 MM COIL WITH DOUBLE O-RING SEALING

The 36 mm coil, thermally insulated in Class H (180°C), is equipped with dual O-Ring sealing, ensuring high resistance to temperature and excellent sealing integrity.

100% HELIUM TESTED

Each unit is individually tested in a state-of-the-art helium facility. Date and serial number are engraved to certify compliance and allow full traceability of recorded performance data.