Notes:

Technical features:

COMPATIBLE A3–A2L REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a (up to +125°C / 257°F).

HFO and HFO/HFC blends: R1234ze, R448A, R449A, R450A, R452A, R1234yf.

HC: R290, R600, R600a.

Products equipped with HNBR seals must not be installed on systems using HCFCs (R22) or any refrigerants mixed with mineral oils or alkylbenzene lubricants.

Our HNBR compound seals have been specifically designed and manufactured for compatibility with A3 and A2L refrigerant gases (as defined in ASHRAE Standard 34). However, due to the countless variables involved in real-world applications—such as pressure, temperature, and mixing ratios—an application-specific validation on the system is always required.

RELIABLE

DURABILITY

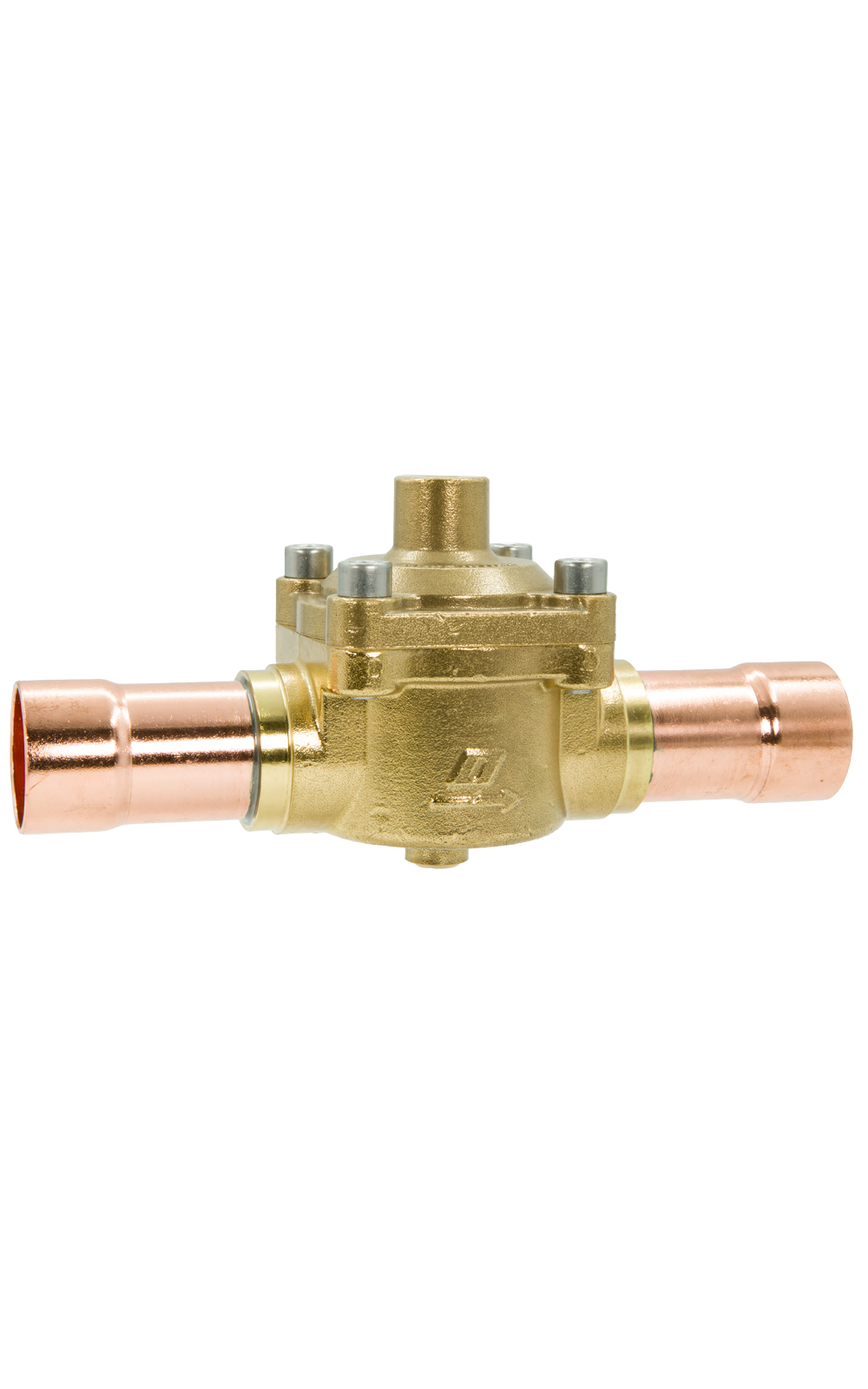

Body made of yellow brass, engineered to ensure strength and long-term

resistance even under demanding conditions.

SECURE

AND CONSISTENT SEALING

Sealing element in PTFE and OLAB-Certified 100% PFAS-FREE HNBR over metal sheet, providing perfect

airtightness in all conditions.

OPTIMIZED

FOR HC REFRIGERANTS

Designed for professional refrigeration systems using hydrocarbon

refrigerants (HC).

TAILORED

OPENING PRESSURES

Available with differential opening pressures of 0.1 – 0.3 – 1.5 bar, to

meet various system requirements.

100% HELIUM TESTED

Each unit is individually tested in a state-of-the-art helium facility. Date and serial number are engraved to certify compliance and allow full traceability of recorded performance data.

Technical features:

COMPATIBLE A3–A2L REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a (up to +125°C / 257°F).

HFO and HFO/HFC blends: R1234ze, R448A, R449A, R450A, R452A, R1234yf.

HC: R290, R600, R600a.

Products equipped with HNBR seals must not be installed on systems using HCFCs (R22) or any refrigerants mixed with mineral oils or alkylbenzene lubricants.

Our HNBR compound seals have been specifically designed and manufactured for compatibility with A3 and A2L refrigerant gases (as defined in ASHRAE Standard 34). However, due to the countless variables involved in real-world applications—such as pressure, temperature, and mixing ratios—an application-specific validation on the system is always required.

RELIABLE

DURABILITY

Body made of yellow brass, engineered to ensure strength and long-term

resistance even under demanding conditions.

SECURE

AND CONSISTENT SEALING

Sealing element in PTFE and OLAB-Certified 100% PFAS-FREE HNBR over metal sheet, providing perfect

airtightness in all conditions.

OPTIMIZED

FOR HC REFRIGERANTS

Designed for professional refrigeration systems using hydrocarbon

refrigerants (HC).

TAILORED

OPENING PRESSURES

Available with differential opening pressures of 0.1 – 0.3 – 1.5 bar, to

meet various system requirements.

100% HELIUM TESTED

Each unit is individually tested in a state-of-the-art helium facility. Date and serial number are engraved to certify compliance and allow full traceability of recorded performance data.