Category: A3-A2L SPECIALIST

Notes:

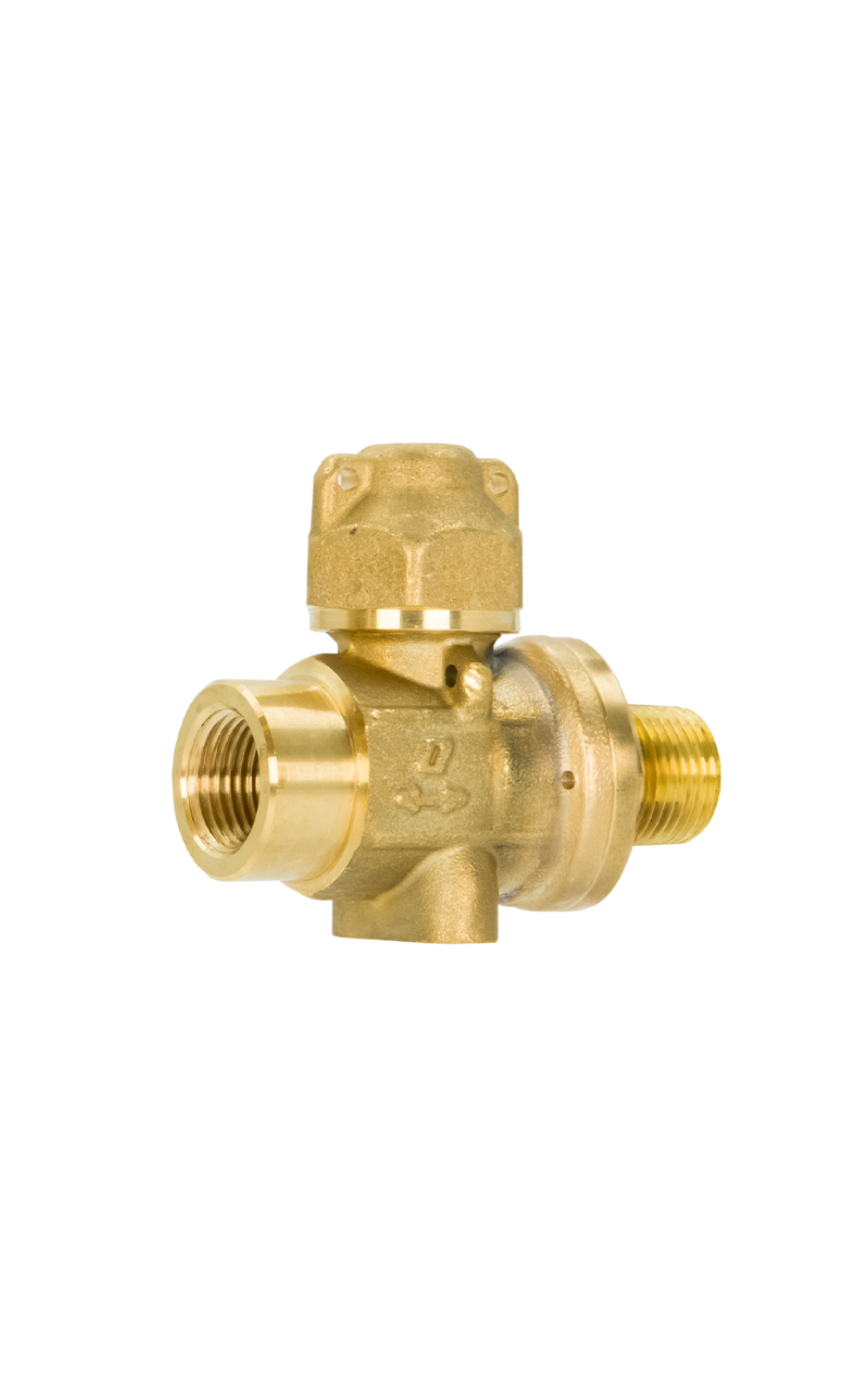

OLAB

Series 37000-FM-2 is the shut-off ball valve designed for safety valve

integration in A3–A2L professional refrigeration systems, offering reliable

performance, high-pressure resistance, and secure sealing over time.

Its spined

brass body allows for a completely mechanical connection, eliminating the

need for welding.

This not only reduces the risk of leaks commonly

associated with brazed joints, but also prevents thermal stress that could

damage the internal O-Rings during assembly or installation.

The AISI 303 stainless steel stem is equipped with double

HNBR 100% PFAS-FREE O-Rings certified by OLAB, also used in the sealing

gasket of the brass cap, ensuring enhanced sealing performance even

under severe conditions. The PTFE seats provide excellent resistance to

chemical and thermal stress, maintaining functionality under the most demanding

operating pressures.

Rated for 52 bar (754 psi) and a temperature range

of –40°C to +150°C (–40°F to +302°F), Series 37000-FM-3 is built to perform

in the most challenging A3–A2L applications.

Each valve is 100% helium tested in OLAB’s dedicated

facility. The laser-marked date and serial number certify the test

results and allow lifetime traceability of performance data. Certified

according to CE and UL 207, this product is part of OLAB’s LOW-PFAS IMPACT

COMPONENTS range—reflecting a commitment to environmental responsibility

without compromising on durability, safety, or reliability.

Technical features:

COMPATIBLE A3–A2L REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a (up to +125°C / 257°F).

HFO and HFO/HFC blends: R1234ze, R448A, R449A, R450A, R452A, R1234yf.

HC: R290, R600, R600a.

Products equipped with HNBR seals must not be installed on systems using HCFCs (R22) or any refrigerants mixed with mineral oils or alkylbenzene lubricants.

Our HNBR compound seals have been specifically designed and manufactured for compatibility with A3 and A2L refrigerant gases (as defined in ASHRAE Standard 34). However, due to the countless variables involved in real-world applications—such as pressure, temperature, and mixing ratios—an application-specific validation on the system is always required.

NO WELDING

Spin-locked body ensures maximum strength and leak-tightness.

ROBUST

Built to withstand working pressures up to 52 bar (754 psi).

SAFE

Reliable sealing guaranteed.

AISI 303 STAINLESS-STEEL STEM

Engineered for long-term durability.

DOUBLE OLAB CERTIFIED 100% PFAS-FREE HNBR O-RING

Positioned on the operating stem for extra protection.

BRASS CLOSING CAP

Fitted with an additional HNBR gasket that maintains the seal even if the stem O-Rings are accidentally damaged.

100% HELIUM TESTED

Each unit is individually tested in a state-of-the-art helium facility. Date and serial number are engraved to certify compliance and allow full traceability of recorded performance data.

OLAB

Series 37000-FM-2 is the shut-off ball valve designed for safety valve

integration in A3–A2L professional refrigeration systems, offering reliable

performance, high-pressure resistance, and secure sealing over time.

Its spined

brass body allows for a completely mechanical connection, eliminating the

need for welding.

This not only reduces the risk of leaks commonly

associated with brazed joints, but also prevents thermal stress that could

damage the internal O-Rings during assembly or installation.

The AISI 303 stainless steel stem is equipped with double

HNBR 100% PFAS-FREE O-Rings certified by OLAB, also used in the sealing

gasket of the brass cap, ensuring enhanced sealing performance even

under severe conditions. The PTFE seats provide excellent resistance to

chemical and thermal stress, maintaining functionality under the most demanding

operating pressures.

Rated for 52 bar (754 psi) and a temperature range

of –40°C to +150°C (–40°F to +302°F), Series 37000-FM-3 is built to perform

in the most challenging A3–A2L applications.

Each valve is 100% helium tested in OLAB’s dedicated

facility. The laser-marked date and serial number certify the test

results and allow lifetime traceability of performance data. Certified

according to CE and UL 207, this product is part of OLAB’s LOW-PFAS IMPACT

COMPONENTS range—reflecting a commitment to environmental responsibility

without compromising on durability, safety, or reliability.

Technical features:

COMPATIBLE A3–A2L REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a (up to +125°C / 257°F).

HFO and HFO/HFC blends: R1234ze, R448A, R449A, R450A, R452A, R1234yf.

HC: R290, R600, R600a.

Products equipped with HNBR seals must not be installed on systems using HCFCs (R22) or any refrigerants mixed with mineral oils or alkylbenzene lubricants.

Our HNBR compound seals have been specifically designed and manufactured for compatibility with A3 and A2L refrigerant gases (as defined in ASHRAE Standard 34). However, due to the countless variables involved in real-world applications—such as pressure, temperature, and mixing ratios—an application-specific validation on the system is always required.

NO WELDING

Spin-locked body ensures maximum strength and leak-tightness.

ROBUST

Built to withstand working pressures up to 52 bar (754 psi).

SAFE

Reliable sealing guaranteed.

AISI 303 STAINLESS-STEEL STEM

Engineered for long-term durability.

DOUBLE OLAB CERTIFIED 100% PFAS-FREE HNBR O-RING

Positioned on the operating stem for extra protection.

BRASS CLOSING CAP

Fitted with an additional HNBR gasket that maintains the seal even if the stem O-Rings are accidentally damaged.

100% HELIUM TESTED

Each unit is individually tested in a state-of-the-art helium facility. Date and serial number are engraved to certify compliance and allow full traceability of recorded performance data.