Ways: 2/2

Notes: OLAB

SOLUTION: THE FIRST INDIRECT ACTING FLANGE SOLENOID VALVE IN THE WORLD, A

HI-QUALITY TECNOLOGY PRODUCT MADE BY OLAB

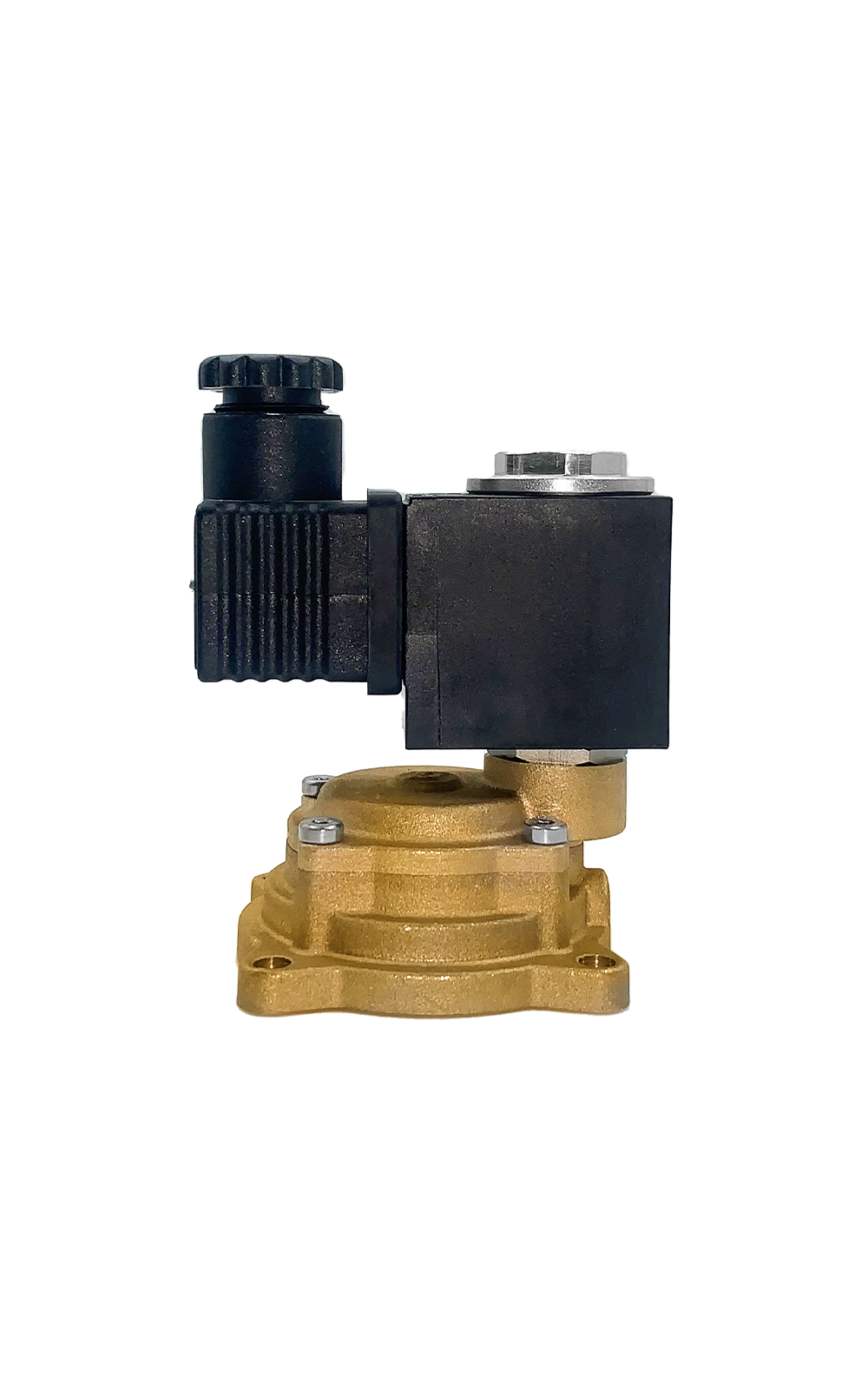

The Series

18001-00 Flanged is a 2/2-way normally closed solenoid valve with

indirect acting system, specifically designed for professional hydraulic

installations where multiple valves need to be mounted in series on

manifolds or modular systems. Its flanged connection allows for quick,

precise, and secure installation, greatly simplifying system integration

and replacement procedures while ensuring maximum reliability.

The valve

body is made of yellow brass, while the sleeve in AISI 304 stainless

steel, equipped with a laser-welded fixed core, ensures excellent mechanical

resistance, durability, and sealing integrity over time, even

under harsh operating conditions. The internal structure is fully inspectable,

allowing direct access to internal components without removing the valve from

the line. This significantly reduces maintenance time and intervention costs,

enabling rapid service even during critical phases of operation.

The

actuation is managed by a 30 mm Ø14 coil (8000BH), built in class H

insulation (180°C / 356°F), providing thermal stability and

continuous performance under demanding workloads.

The indirect action

design supports high pressure differentials and large orifice

diameters, ensuring a smooth and reliable response even in systems with

strong flow requirements.

This

solution is engineered to guarantee maximum operational continuity:

maintenance can be carried out by non-specialized personnel, thanks to

the intuitive structure and easy internal access. As a result, downtime is

minimized, and the overall system efficiency is significantly

improved.

The Series

18001-00 Flanged represents a true innovation: the first indirect acting

solenoid valve in the world with flanged connection, a Hi-Quality

Technology product fully designed and manufactured by OLAB. It is

the ideal pairing with OLAB aluminium manifolds K09726, allowing for

highly compact, modular, and service-friendly configurations.

The valve

supports a maximum operating pressure of 20 bar (290 psi). Temperature

ranges vary depending on the gasket material: EPDM from –20°C to +90°C (–4°F

÷ +194°F), RBX from –30°C to +145°C (–22°F ÷ +293°F), NBR from

–15°C to +150°C (+5°F ÷ +302°F). It is certified CE, VDE, UL, and rated IP65,

ensuring full compliance with international safety and quality standards.

Technical features:

BODY WITH FLANGED CONNECTION

The flanged design allows for fast, accurate, and secure installation, making it ideal for series-mounted assemblies on manifolds or modular systems.

DESIGNED FOR EASY ASSEMBLY

Each component has been engineered to simplify integration into the system, reducing both time and complexity during installation and replacement phases.

QUICK SYSTEM MAINTENANCE

The inspectable configuration provides direct access to internal components without the need to remove the valve from the circuit.

DESIGNED TO REDUCE SERVICE COSTS

Thanks to the accessible internal design and ease of replacement, the overall cost of maintenance and system downtime is significantly reduced.

MINIMIZED SYSTEM DOWNTIME

The flanged layout and simplified maintenance procedure help minimize system interruptions, ensuring continuous and reliable operation.

MAINTENANCE DOES NOT REQUIRE SPECIALIZED PERSONNEL

The intuitive design and mechanical accessibility allow maintenance to be carried out safely and efficiently, even by non-specialized operators.

The Series

18001-00 Flanged is a 2/2-way normally closed solenoid valve with

indirect acting system, specifically designed for professional hydraulic

installations where multiple valves need to be mounted in series on

manifolds or modular systems. Its flanged connection allows for quick,

precise, and secure installation, greatly simplifying system integration

and replacement procedures while ensuring maximum reliability.

The valve

body is made of yellow brass, while the sleeve in AISI 304 stainless

steel, equipped with a laser-welded fixed core, ensures excellent mechanical

resistance, durability, and sealing integrity over time, even

under harsh operating conditions. The internal structure is fully inspectable,

allowing direct access to internal components without removing the valve from

the line. This significantly reduces maintenance time and intervention costs,

enabling rapid service even during critical phases of operation.

The

actuation is managed by a 30 mm Ø14 coil (8000BH), built in class H

insulation (180°C / 356°F), providing thermal stability and

continuous performance under demanding workloads.

The indirect action

design supports high pressure differentials and large orifice

diameters, ensuring a smooth and reliable response even in systems with

strong flow requirements.

This

solution is engineered to guarantee maximum operational continuity:

maintenance can be carried out by non-specialized personnel, thanks to

the intuitive structure and easy internal access. As a result, downtime is

minimized, and the overall system efficiency is significantly

improved.

The Series

18001-00 Flanged represents a true innovation: the first indirect acting

solenoid valve in the world with flanged connection, a Hi-Quality

Technology product fully designed and manufactured by OLAB. It is

the ideal pairing with OLAB aluminium manifolds K09726, allowing for

highly compact, modular, and service-friendly configurations.

The valve

supports a maximum operating pressure of 20 bar (290 psi). Temperature

ranges vary depending on the gasket material: EPDM from –20°C to +90°C (–4°F

÷ +194°F), RBX from –30°C to +145°C (–22°F ÷ +293°F), NBR from

–15°C to +150°C (+5°F ÷ +302°F). It is certified CE, VDE, UL, and rated IP65,

ensuring full compliance with international safety and quality standards.

Technical features:

BODY WITH FLANGED CONNECTION

The flanged design allows for fast, accurate, and secure installation, making it ideal for series-mounted assemblies on manifolds or modular systems.

DESIGNED FOR EASY ASSEMBLY

Each component has been engineered to simplify integration into the system, reducing both time and complexity during installation and replacement phases.

QUICK SYSTEM MAINTENANCE

The inspectable configuration provides direct access to internal components without the need to remove the valve from the circuit.

DESIGNED TO REDUCE SERVICE COSTS

Thanks to the accessible internal design and ease of replacement, the overall cost of maintenance and system downtime is significantly reduced.

MINIMIZED SYSTEM DOWNTIME

The flanged layout and simplified maintenance procedure help minimize system interruptions, ensuring continuous and reliable operation.

MAINTENANCE DOES NOT REQUIRE SPECIALIZED PERSONNEL

The intuitive design and mechanical accessibility allow maintenance to be carried out safely and efficiently, even by non-specialized operators.