Ways: 2/2

Notes:

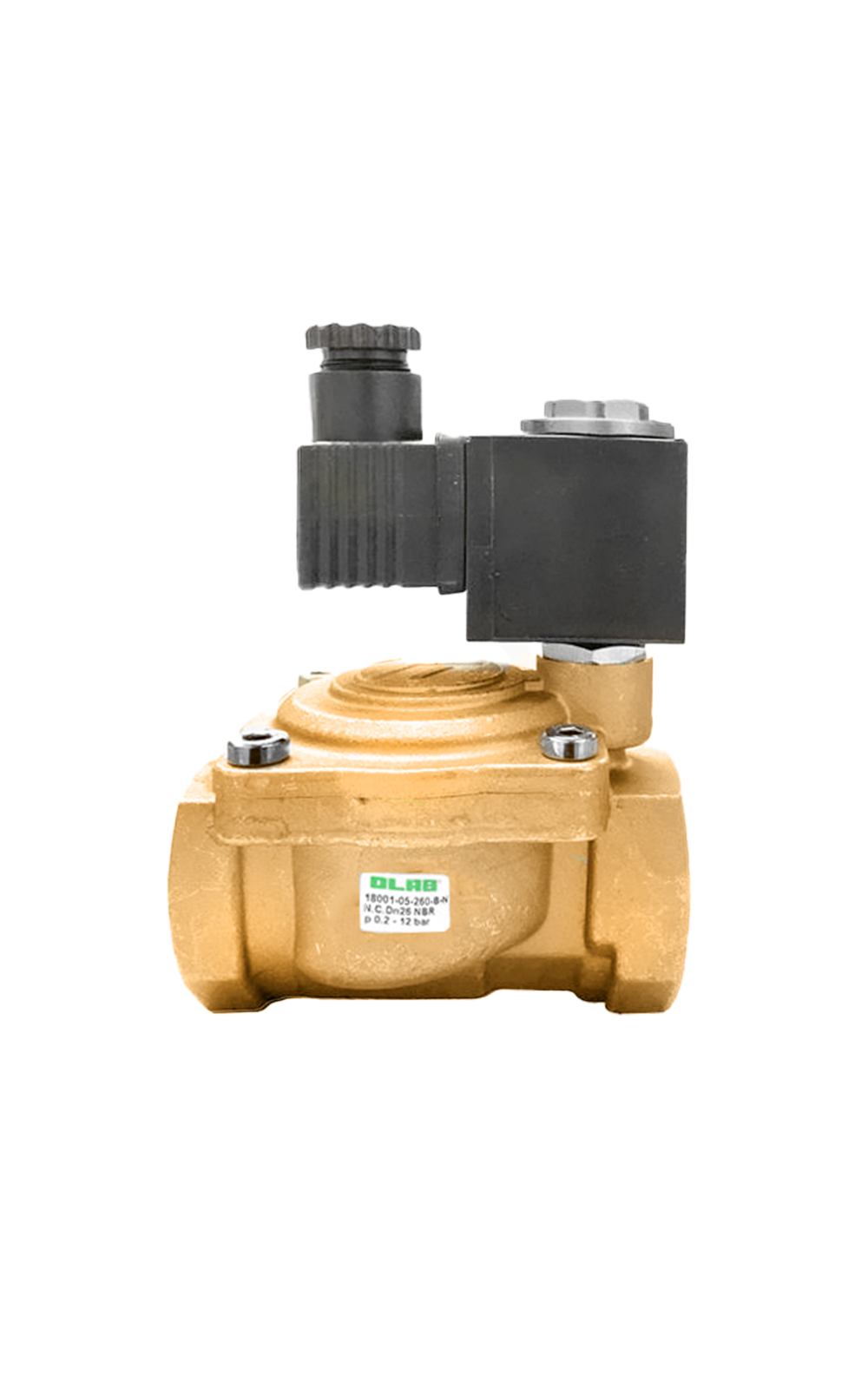

The Series 18001 is a 2/2-way normally closed

solenoid valve with indirect acting system, designed for professional

hydraulic installations requiring long-term reliability and resistance

to pressure and thermal stress. Its pilot-operated operation allows

for the management of high flow rates and significant pressure

differentials, while ensuring low power consumption by the solenoid

coil.

At the core of the assembly is a sleeve in AISI 304

stainless steel, equipped with a laser-welded fixed core, offering

excellent mechanical strength and sealing reliability even in

heavy-duty conditions. The valve body, made of CW510L OT57 lead-free

brass, complies with international standards for drinking water

applications, making it suitable for both industrial and civil

environments.

The valve is equipped with a 30 mm coil (8000BH) with

an Ø14 mm bore, manufactured in class H insulation, capable of

withstanding continuous operation up to 180°C (356°F). The sealing

system is available in EPDM, RBX, or NBR, selected

according to the type of fluid and required temperature range.

The valve operates at pressures up to 20 bar (290 psi),

making it ideal for systems exposed to high mechanical loads.

The IP65

protection class ensures safe operation even in humid or dusty

environments. Its fully inspectable design allows for internal

maintenance without removing the valve from the system, significantly

reducing downtime and simplifying service operations.

The temperature range depends on the sealing

material: EPDM from –20°C to +90°C (–4°F to +194°F), RBX from –30°C

to +145°C (–22°F to +293°F), and NBR from –15°C to +150°C (+5°F to

+302°F).

The valve is certified VDE, UL, NSF

COMPONENT, and NSF/ANSI/CAN 61, ensuring full compliance with international

quality, electrical safety, and potable water contact standards, making it

suitable for a wide range of applications including food-grade systems

and potable water circuits.

Technical features:

Thermo-hydraulic systems, autoclaves, machine tool cooling systems, washing systems, irrigation systems, fire-fighting systems, sanitation systems, pressure washers.

SUITABLE FOR FOOD CONTACT

Manufactured with materials compliant with food-grade regulations, it ensures safety in all applications involving direct contact with fluids intended for human consumption.

DESIGNED FOR POTABLE WATER APPLICATIONS

The lead-free OT57 brass body and carefully selected internal components guarantee full compatibility with systems for the treatment and distribution of drinking water.

ENGINEERED FOR HEAVY-DUTY OPERATION WHERE THE COIL IS HIGHLY STRESSED

The 30 mm coil, built in class H insulation, is designed to withstand continuous cycles, thermal peaks and demanding operating conditions without loss of performance.

HIGH OPENING DIFFERENTIALS WITH LARGE ORIFICE PASSAGE

The pilot-operated system handles significant pressure differences even with enlarged flow sections, maintaining a smooth and stable response.

LOW SOLENOID POWER WITH HIGH OPERATING PRESSURES

Thanks to the indirect action principle, the valve operates efficiently even at high pressures, requiring minimal power to activate the solenoid.

The valve can be installed in any position but not with the coil down. The ideal installation position is with the coil oriented vertically upwards. Maximum cleaning of the circuit is recommended, paying particular attention during the assembly phase.

The Series 18001 is a 2/2-way normally closed

solenoid valve with indirect acting system, designed for professional

hydraulic installations requiring long-term reliability and resistance

to pressure and thermal stress. Its pilot-operated operation allows

for the management of high flow rates and significant pressure

differentials, while ensuring low power consumption by the solenoid

coil.

At the core of the assembly is a sleeve in AISI 304

stainless steel, equipped with a laser-welded fixed core, offering

excellent mechanical strength and sealing reliability even in

heavy-duty conditions. The valve body, made of CW510L OT57 lead-free

brass, complies with international standards for drinking water

applications, making it suitable for both industrial and civil

environments.

The valve is equipped with a 30 mm coil (8000BH) with

an Ø14 mm bore, manufactured in class H insulation, capable of

withstanding continuous operation up to 180°C (356°F). The sealing

system is available in EPDM, RBX, or NBR, selected

according to the type of fluid and required temperature range.

The valve operates at pressures up to 20 bar (290 psi),

making it ideal for systems exposed to high mechanical loads.

The IP65

protection class ensures safe operation even in humid or dusty

environments. Its fully inspectable design allows for internal

maintenance without removing the valve from the system, significantly

reducing downtime and simplifying service operations.

The temperature range depends on the sealing

material: EPDM from –20°C to +90°C (–4°F to +194°F), RBX from –30°C

to +145°C (–22°F to +293°F), and NBR from –15°C to +150°C (+5°F to

+302°F).

The valve is certified VDE, UL, NSF

COMPONENT, and NSF/ANSI/CAN 61, ensuring full compliance with international

quality, electrical safety, and potable water contact standards, making it

suitable for a wide range of applications including food-grade systems

and potable water circuits.

Technical features:

Thermo-hydraulic systems, autoclaves, machine tool cooling systems, washing systems, irrigation systems, fire-fighting systems, sanitation systems, pressure washers.

SUITABLE FOR FOOD CONTACT

Manufactured with materials compliant with food-grade regulations, it ensures safety in all applications involving direct contact with fluids intended for human consumption.

DESIGNED FOR POTABLE WATER APPLICATIONS

The lead-free OT57 brass body and carefully selected internal components guarantee full compatibility with systems for the treatment and distribution of drinking water.

ENGINEERED FOR HEAVY-DUTY OPERATION WHERE THE COIL IS HIGHLY STRESSED

The 30 mm coil, built in class H insulation, is designed to withstand continuous cycles, thermal peaks and demanding operating conditions without loss of performance.

HIGH OPENING DIFFERENTIALS WITH LARGE ORIFICE PASSAGE

The pilot-operated system handles significant pressure differences even with enlarged flow sections, maintaining a smooth and stable response.

LOW SOLENOID POWER WITH HIGH OPERATING PRESSURES

Thanks to the indirect action principle, the valve operates efficiently even at high pressures, requiring minimal power to activate the solenoid.

The valve can be installed in any position but not with the coil down. The ideal installation position is with the coil oriented vertically upwards. Maximum cleaning of the circuit is recommended, paying particular attention during the assembly phase.