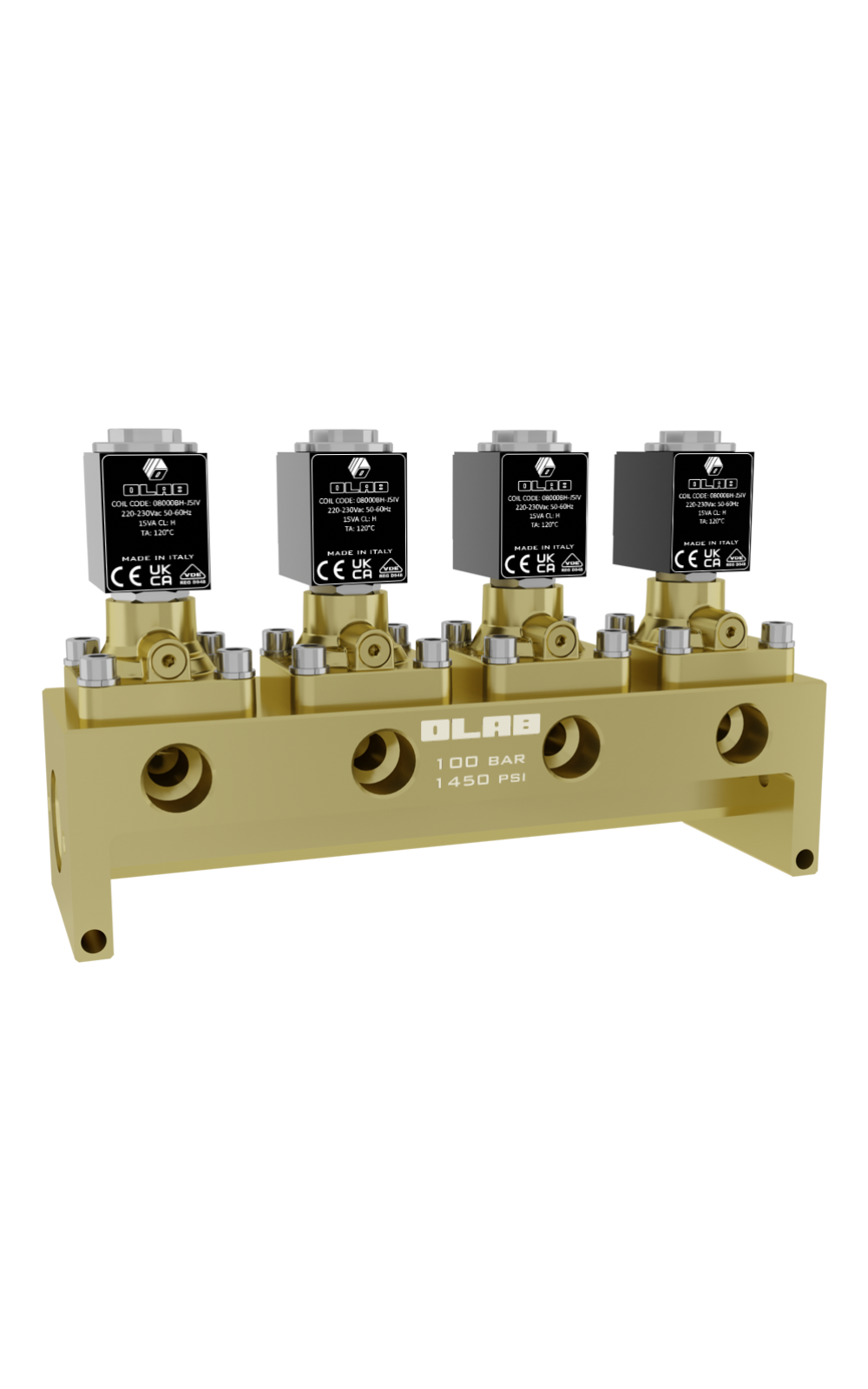

Category: INDIRECT AND MIXED ACTION SOLENOID VALVES

Ways: 2/2 N.C.

Notes: PS: 100 bar (1450 psi)

OPD: min 3 bar / max 90 bar (min 44 psi / max 1305 psi)

DN: 12mm (0,47")

CERTIFICATIONS: CE, IP65

The K10083

Series is a multiposition manifold developed for in-line

installation of flanged solenoid valves, designed for professional

applications where modularity, durability, and easy maintenance are essential.

It

is part of the OLAB Car Wash line and fully integrates into the X-TREME PRO range, dedicated to high-pressure systems.

Manufactured in CW617N OT58 brass, it features a side

inlet and independent front outlets, enabling simpler maintenance

and greater safety during localized service operations. Internally, it includes

a PP-H piston, stainless steel seal seat, AISI 303 insert,

and an AISI 304L stainless steel sleeve laser-welded with OLAB in-house

technology—ensuring perfect sealing and long-lasting reliability.

Sealing is provided by NBR or OLAB-certified FKM Plus

Hi-Performance gaskets, ensuring compatibility with water, detergents, and

high-temperature fluids.

The electrical section uses the OLAB 8000BH coil

(30 mm Ø14), with class H insulation (180°C) and IP65 protection,

suitable for harsh environments such as wash tunnels and automated bays.

With a maximum pressure (PS) of 100 bar (1450 psi), OPD

from 3 to 90 bar (44–1305 psi), and DN 12 mm (0.47"), the

K10083 Series is the ideal solution for high-performance Car Wash

installations, where long-term reliability and operational efficiency are

key.

CE certified, in compliance with European safety and

industrial standards.

Technical features:

The K10083

Series is a multiposition manifold developed for in-line

installation of flanged solenoid valves, designed for professional

applications where modularity, durability, and easy maintenance are essential.

It

is part of the OLAB Car Wash line and fully integrates into the X-TREME PRO range, dedicated to high-pressure systems.

Manufactured in CW617N OT58 brass, it features a side

inlet and independent front outlets, enabling simpler maintenance

and greater safety during localized service operations. Internally, it includes

a PP-H piston, stainless steel seal seat, AISI 303 insert,

and an AISI 304L stainless steel sleeve laser-welded with OLAB in-house

technology—ensuring perfect sealing and long-lasting reliability.

Sealing is provided by NBR or OLAB-certified FKM Plus

Hi-Performance gaskets, ensuring compatibility with water, detergents, and

high-temperature fluids.

The electrical section uses the OLAB 8000BH coil

(30 mm Ø14), with class H insulation (180°C) and IP65 protection,

suitable for harsh environments such as wash tunnels and automated bays.

With a maximum pressure (PS) of 100 bar (1450 psi), OPD

from 3 to 90 bar (44–1305 psi), and DN 12 mm (0.47"), the

K10083 Series is the ideal solution for high-performance Car Wash

installations, where long-term reliability and operational efficiency are

key.

CE certified, in compliance with European safety and

industrial standards.

Technical features: