Notes: INNOVATION OF THE YEAR NOMINEE - ATMOSummit America 2025

IMPORTANT NOTE: The orientation of swivel fittings must be performed when the device is not pressurized. If the device is pressurized, only small directional adjustments are permitted.

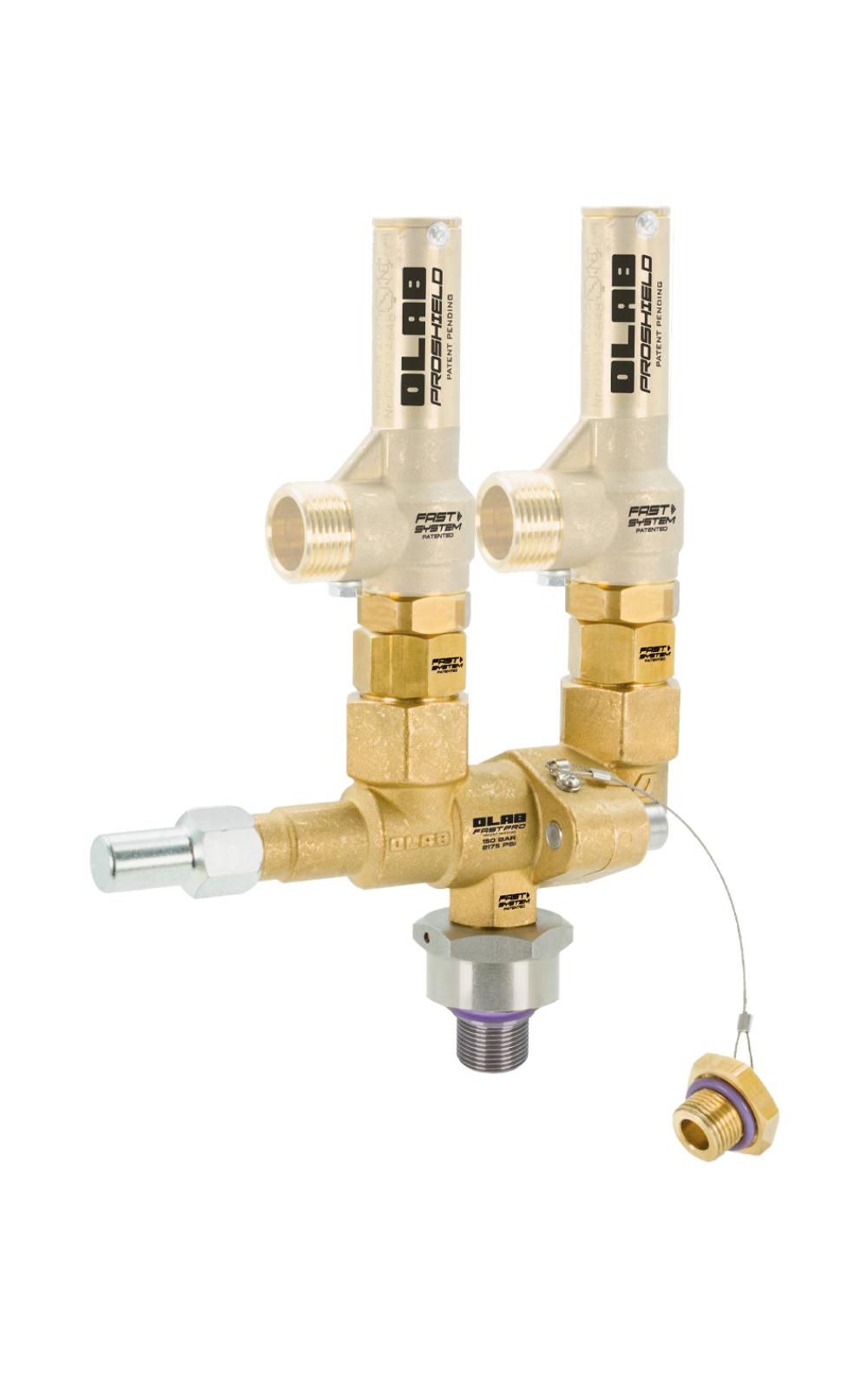

OLAB

FastPro (Patent Pending) is the new benchmark for safety management in professional CO2

(R744) transcritical systems, up to 150 bar (2175 psi). Recognised

as an Innovation of the Year nominee at the ATMO Summit America 2025,

and built around OLAB’s FastSystem (Patented) connection technology,

this 360° swivelling change-over represents the perfect combination of innovation,

efficiency and reliability.

FastPro installs in 30 seconds, with no need

for Teflon, Loctite, or specialised personnel. The FastSystem

(Patented) connection enables a simple, fast, and precise assembly,

significantly reducing time, cost, and operational complexity. Even in

challenging environments or tight spaces, FastPro adapts without the need

for rework. Thanks to the fully swivelling design of the entire valve body

and safety valves, it allows complete orientation before and after

installation, making the system easy to access, configure, and adapt to any

plant layout.

Each potential leak point is sealed with double

OLAB-certified, 100 % PFAS-FREE EPDM O-Rings, winner of the Innovation

of the Year award at ATMO Europe 2024, ensuring perfect and stable

sealing even under extreme conditions. The entire component is 100%

PFAS-FREE, guaranteeing maximum environmental safety and full compliance

with new regulations.

FastPro is available with a customisable sleeve (sold separately) in

brass or stainless steel, in both threaded and weldable versions, to suit

every project requirement and installation standard. It is designed to ensure

constant system protection: one valve remains active while the other is

isolated, allowing safe replacement without stopping the system.

ProShield safety valves connect exclusively to FastPro

through the FastSystem (Patented) interface, ensuring precise, leak-free

installation. Equipped with ISO cylindrical gas thread and OLAB-certified,

100% PFAS-FREE EPDM O-Rings, these valves also allow controlled venting

of excess CO2 during replacement—a key feature in high-pressure

transcritical systems. ProShield valves are certified for both

subcritical (up to 60 bar) and transcritical (up to 300 bar) systems, in

accordance with the most demanding international regulations: CE, D.E.

2014/68/EU (PED), ASME XIII, SELO, UKCA, EAC TR CU 032-010-012, ATEX, UKEX,

and Canadian registration. The highest standard of safety, innovation, and

sustainability.

FastPro and ProShield together offer a revolutionary,

integrated solution: installation in 30 seconds even on

transcritical CO2 systems at 150 bar (2175 psi); perfect

sealing with OLAB-certified, 100% PFAS-FREE EPDM O-Rings; 360°

rotation before and after installation; customisable sleeve (sold separately) in brass

or stainless steel; compatibility with critical systems and international

certifications. A complete, pressure-proof solution designed to simplify

installation, ensure continuous safety, eliminate leakage, and reduce

environmental impact—without compromise.

Technical features:

100% NO

LEAKAGE

Total sealing up to 150 bar (2175 psi) ensured by double O-Rings in

OLAB-certified EPDM 100% PFAS-FREE at every potential leakage point.

FASTSYSTEM

CONNECTION: 30-SECOND INSTALLATION

No Teflon, no Loctite, no specialized personnel required.

100%

PFAS-FREE

Fully certified 100% PFAS-FREE component.

360°

ORIENTATION

Body and safety valves freely rotate before and after installation, even in

tight spaces.

CHOOSE

YOUR CONNECTION

Customizable sleeve for any layout: brass or stainless steel, threaded or

socket weld.

EXCLUSIVE

OLAB PROSHIELD SAFETY VALVE

Dedicated connection to OLAB ProShield safety valves, certified up to 300 bar.

UNINTERRUPTED

OPERATION

One valve remains active while the other is isolated: replacement without

system shutdown.

CONTROLLED

VENTING

Cylindrical thread: safe CO2 discharge during PRV replacement.

TOTAL

SAVINGS

Less time, less labor, lower operational costs.

OLAB

FastPro (Patent Pending) is the new benchmark for safety management in professional CO2

(R744) transcritical systems, up to 150 bar (2175 psi). Recognised

as an Innovation of the Year nominee at the ATMO Summit America 2025,

and built around OLAB’s FastSystem (Patented) connection technology,

this 360° swivelling change-over represents the perfect combination of innovation,

efficiency and reliability.

FastPro installs in 30 seconds, with no need

for Teflon, Loctite, or specialised personnel. The FastSystem

(Patented) connection enables a simple, fast, and precise assembly,

significantly reducing time, cost, and operational complexity. Even in

challenging environments or tight spaces, FastPro adapts without the need

for rework. Thanks to the fully swivelling design of the entire valve body

and safety valves, it allows complete orientation before and after

installation, making the system easy to access, configure, and adapt to any

plant layout.

Each potential leak point is sealed with double

OLAB-certified, 100 % PFAS-FREE EPDM O-Rings, winner of the Innovation

of the Year award at ATMO Europe 2024, ensuring perfect and stable

sealing even under extreme conditions. The entire component is 100%

PFAS-FREE, guaranteeing maximum environmental safety and full compliance

with new regulations.

FastPro is available with a customisable sleeve (sold separately) in

brass or stainless steel, in both threaded and weldable versions, to suit

every project requirement and installation standard. It is designed to ensure

constant system protection: one valve remains active while the other is

isolated, allowing safe replacement without stopping the system.

ProShield safety valves connect exclusively to FastPro

through the FastSystem (Patented) interface, ensuring precise, leak-free

installation. Equipped with ISO cylindrical gas thread and OLAB-certified,

100% PFAS-FREE EPDM O-Rings, these valves also allow controlled venting

of excess CO2 during replacement—a key feature in high-pressure

transcritical systems. ProShield valves are certified for both

subcritical (up to 60 bar) and transcritical (up to 300 bar) systems, in

accordance with the most demanding international regulations: CE, D.E.

2014/68/EU (PED), ASME XIII, SELO, UKCA, EAC TR CU 032-010-012, ATEX, UKEX,

and Canadian registration. The highest standard of safety, innovation, and

sustainability.

FastPro and ProShield together offer a revolutionary,

integrated solution: installation in 30 seconds even on

transcritical CO2 systems at 150 bar (2175 psi); perfect

sealing with OLAB-certified, 100% PFAS-FREE EPDM O-Rings; 360°

rotation before and after installation; customisable sleeve (sold separately) in brass

or stainless steel; compatibility with critical systems and international

certifications. A complete, pressure-proof solution designed to simplify

installation, ensure continuous safety, eliminate leakage, and reduce

environmental impact—without compromise.

Technical features:

100% NO

LEAKAGE

Total sealing up to 150 bar (2175 psi) ensured by double O-Rings in

OLAB-certified EPDM 100% PFAS-FREE at every potential leakage point.

FASTSYSTEM

CONNECTION: 30-SECOND INSTALLATION

No Teflon, no Loctite, no specialized personnel required.

100%

PFAS-FREE

Fully certified 100% PFAS-FREE component.

360°

ORIENTATION

Body and safety valves freely rotate before and after installation, even in

tight spaces.

CHOOSE

YOUR CONNECTION

Customizable sleeve for any layout: brass or stainless steel, threaded or

socket weld.

EXCLUSIVE

OLAB PROSHIELD SAFETY VALVE

Dedicated connection to OLAB ProShield safety valves, certified up to 300 bar.

UNINTERRUPTED

OPERATION

One valve remains active while the other is isolated: replacement without

system shutdown.

CONTROLLED

VENTING

Cylindrical thread: safe CO2 discharge during PRV replacement.

TOTAL

SAVINGS

Less time, less labor, lower operational costs.