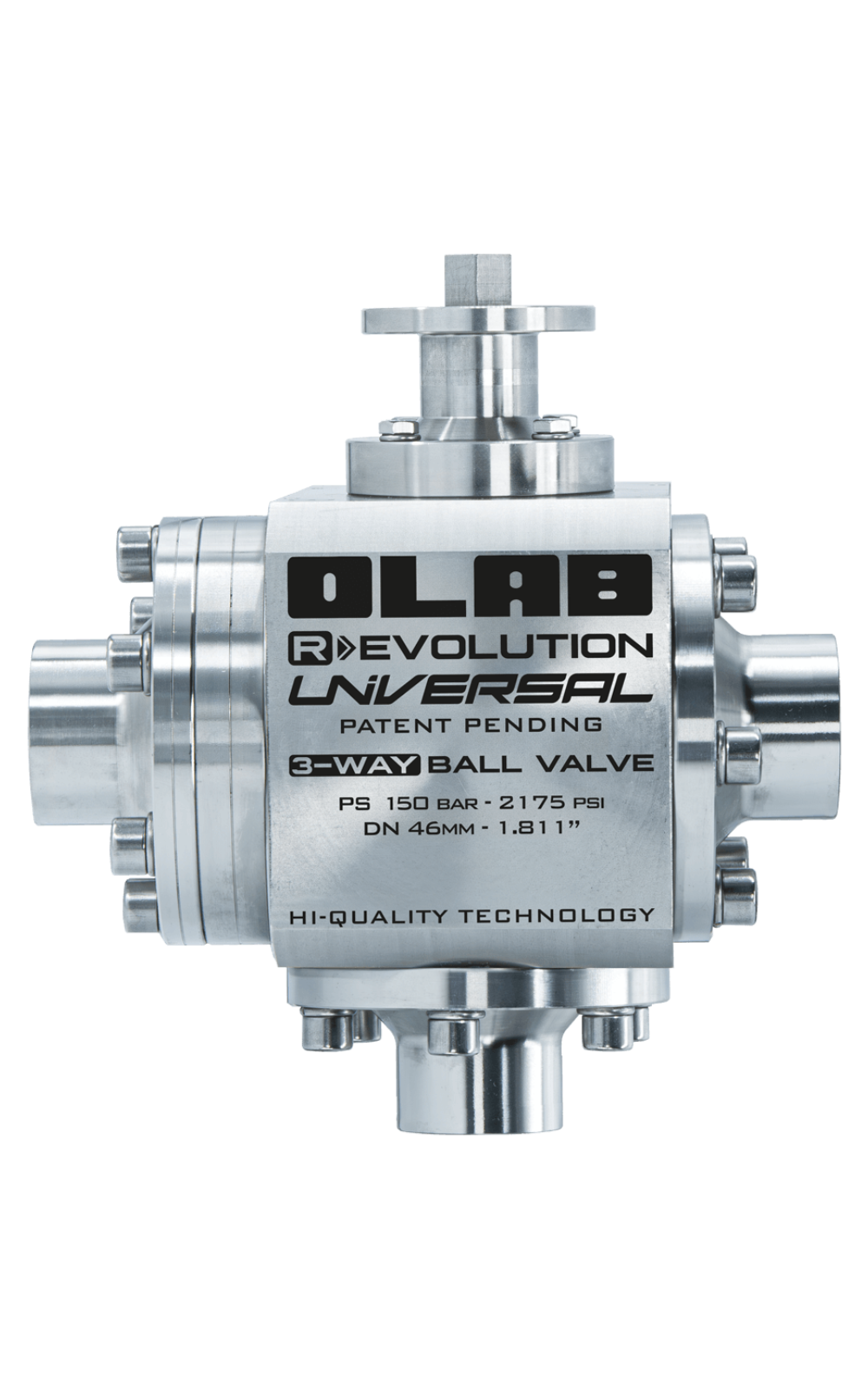

Extremely high performance, up to 150 bar/2175 psi guaranteed, zero welding, zero leakage.

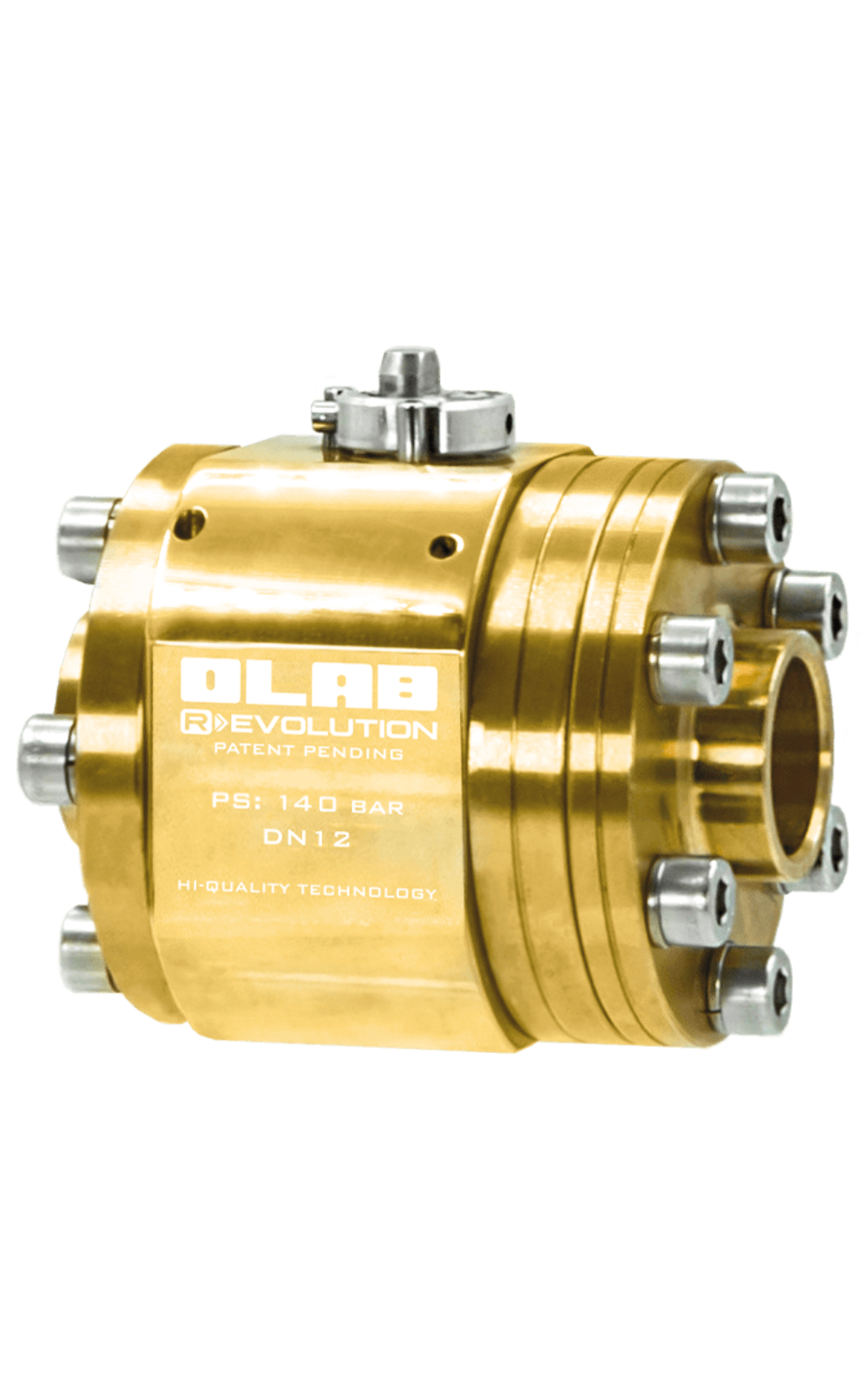

OLAB Ecosystem redefines professional refrigeration systems for R744 with the Ball Valve Specialist line, Series Revolution, and Fast Lock CO2, eliminating the problems of traditional solutions and optimizing energy, time, and costs.

Solenoid valves, valves, and fittings of the highest quality and reliability, UL certified to meet the needs of international markets.

3-WAY FLANGED BALL VALVE - AISI 304L STAINLESS STEEL BODY - UNIVERSAL ACTUATOR-READY - BRASS, STAINLESS STEEL OR STAINLESS STEEL V-SHAPE BALL - 100% PFAS-FREE OLAB CERTIFIED DOUBLE EPDM O.RING

2-WAY FLANGED BALL VALVE - AISI 304L STAINLESS STEEL BODY - UNIVERSAL ACTUATOR-READY - BRASS, STAINLESS STEEL OR STAINLESS STEEL V-SHAPE BALL - 100% PFAS-FREE OLAB CERTIFIED DOUBLE EPDM O.RING

2-WAY FLANGED BALL VALVE - AISI 304L STAINLESS STEEL BODY - MANUALLY OPERATED - WITH OR WITHOUT STEM PROTECTION CAP - 100% PFAS-FREE OLAB CERTIFIED DOUBLE EPDM O.RING

2-WAY FLANGED BALL VALVE - BRASS BODY - MANUALLY OPERATED - WITHOUT STEM PROTECTION CAP - 100% PFAS-FREE OLAB CERTIFIED DOUBLE EPDM O.RING

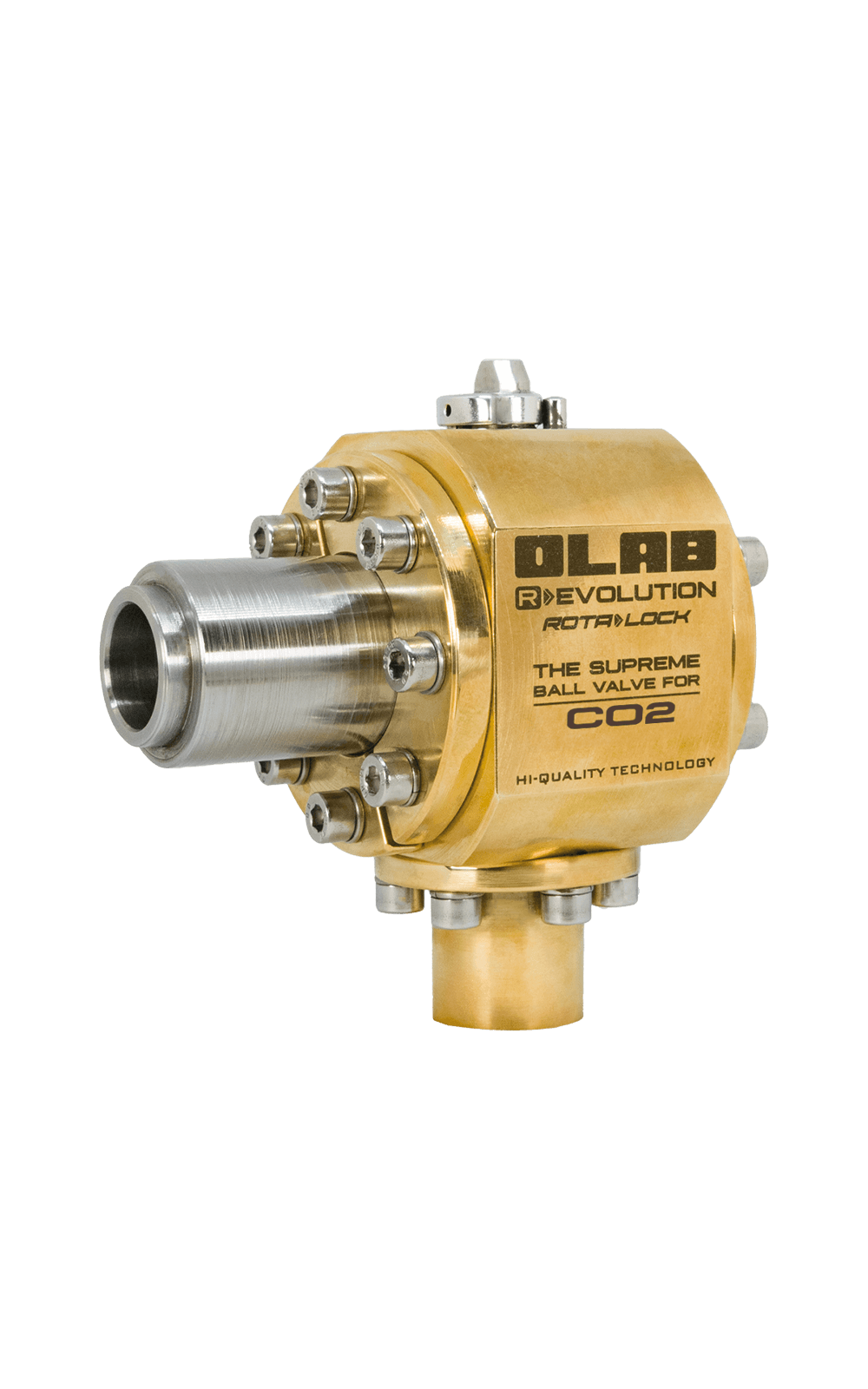

ROTALOCK BALL VALVE WITH REVOLUTION TECHNOLOGY – P355N WELDING CONNECTION FOR TANK – BODY IN CW614N–OT58 BRASS - 100% PFAS-FREE OLAB CERTIFIED DOUBLE EPDM O.RING

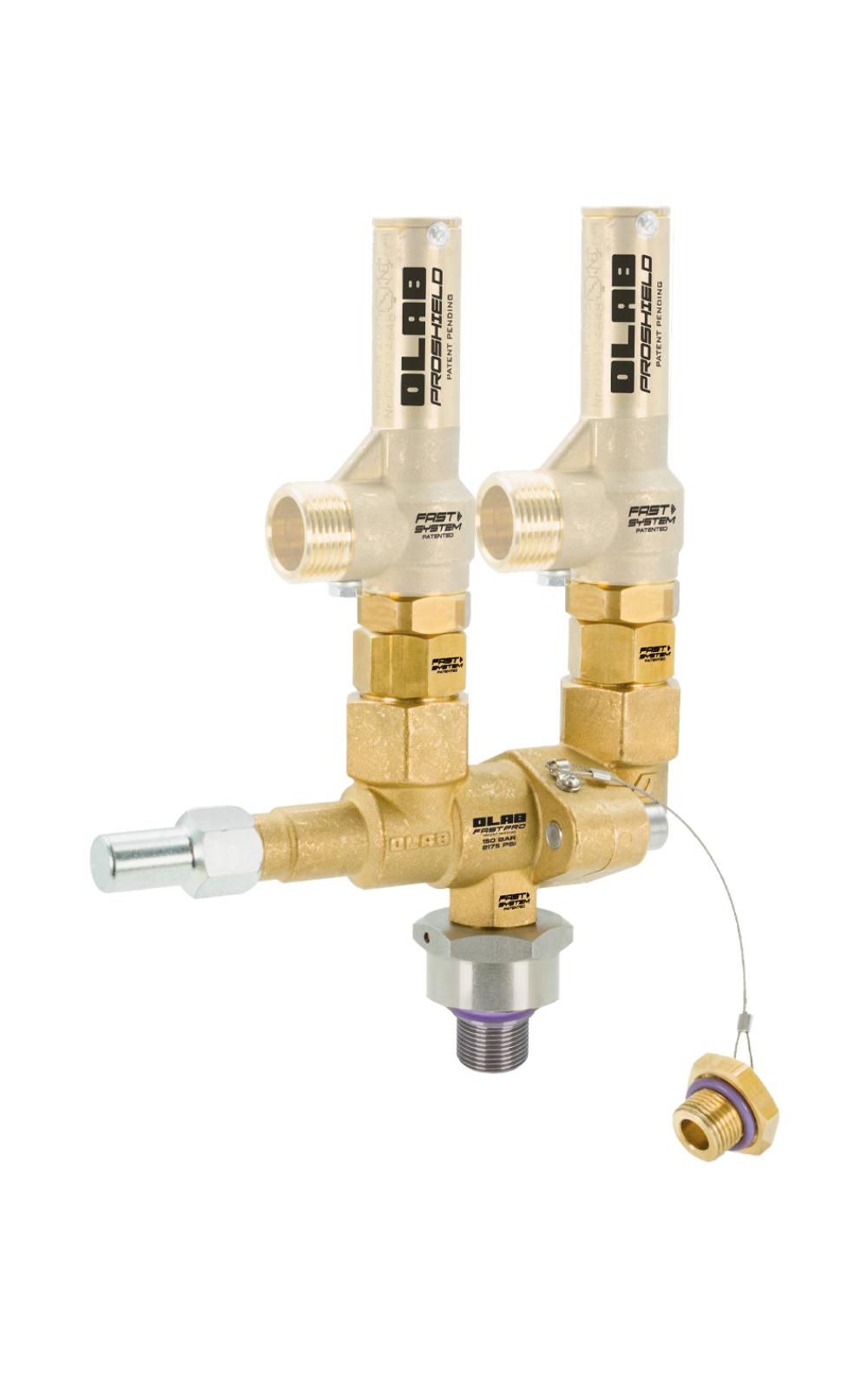

SHUT OFF VALVES FOR PROSHIELD SAFETY VALVES CONNECTION - BRASS BODY - STAINLESS STEEL CLOSING FLANGE - STAINLESS STEEL SCREWS - CW614N-OT58 FAST SYSTEM (PATENTED) SWIVEL BRASS FITTING - DOUBLE OLAB CERTIFIED 100%

CHECK VALVE WITH REVOLUTION CONNECTION SYSTEM - AISI 304L STAINLESS STEEL BODY AND FLANGES - 100% PFAS-FREE OLAB CERTIFIED EPDM O.RING

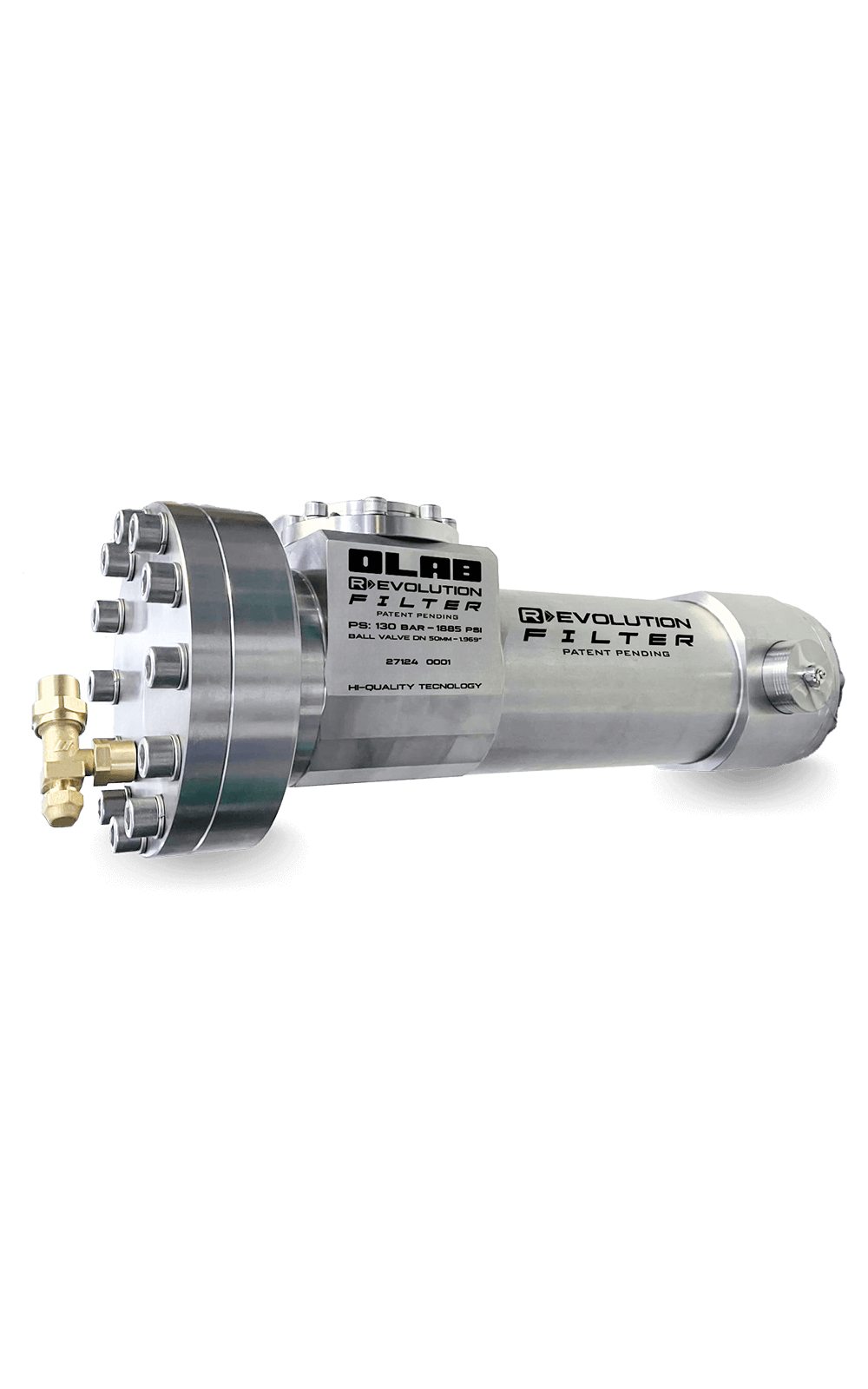

STAINLESS STEEL DEHYDRATOR FILTER WITH 90° CONNECTIONS - INTEGRATED REVOLUTION BALL VALVE AND RECEIVER VALVE - DOUBLE OLAB-CERTIFIED 100% PFAS-FREE EPDM O.RING - FOR TRANSCRITICAL SYSTEMS

STAINLESS STEEL AXIAL FLANGED DEHYDRATOR FILTER WITH DOUBLE REPLACEABLE SOLID CARTRIDGES - INTEGRATED ROTATING RECEIVER VALVE FOR CHARGE/DISCHARGE - 100% PFAS-FREE OLAB CERTIFIED DOUBLE EPDM O.RING - FOR TRANSCRITICAL SYSTEMS

BI-DIRECTIONAL BALL VALVE - BRASS BODY - FASTLOCK CO2 CONNECTION FOR STAINLESS STEEL AND K65 COPPER PIPES - INTEGRATED ACCESS FITTING WITH DOUBLE O.RING CAP - 100% PFAS-FREE OLAB CERTIFIED DOUBLE EPDM O.RING

REVOLUTIONARY CO2 BALL VALVE - BRASS BODY - FASTLOCK CO2 CONNECTION - INTEGRATED ACCESS FITTING WITH DOUBLE O.RING CAP - 100% PFAS-FREE OLAB CERTIFIED EPDM O.RING

2/2-WAY N.C. DIRECT-ACTING SOLENOID VALVE - STAINLESS STEEL BODY - FASTLOCK CO2 CONNECTION - 36MM Ø14 CLASS H COIL WITH IP67 CONNECTOR - 100% PFAS-FREE OLAB CERTIFIED EPDM O.RING

2/2-WAY N.C. SOLENOID EXPANSION VALVE - FASTLOCK CO2 CONNECTION FOR STAINLESS STEEL AND K65 PIPE - INTERCHANGEABLE ORIFICE - DRIVER OPTION - UL CERTIFIED 36MM CLASS H COIL WITH IP67 CONNECTOR - 100% PFAS-FREE OLAB CERTIFIED EPDM O.RING

2/2-WAY N.C. SERVO-CONTROLLED PISTON SOLENOID VALVE - FASTLOCK CO2 CONNECTION FOR STAINLESS STEEL AND K65 PIPE - UL CERTIFIED 36MM CLASS H COIL WITH IP67 CONNECTOR - 100% PFAS-FREE OLAB CERTIFIED EPDM O.RING

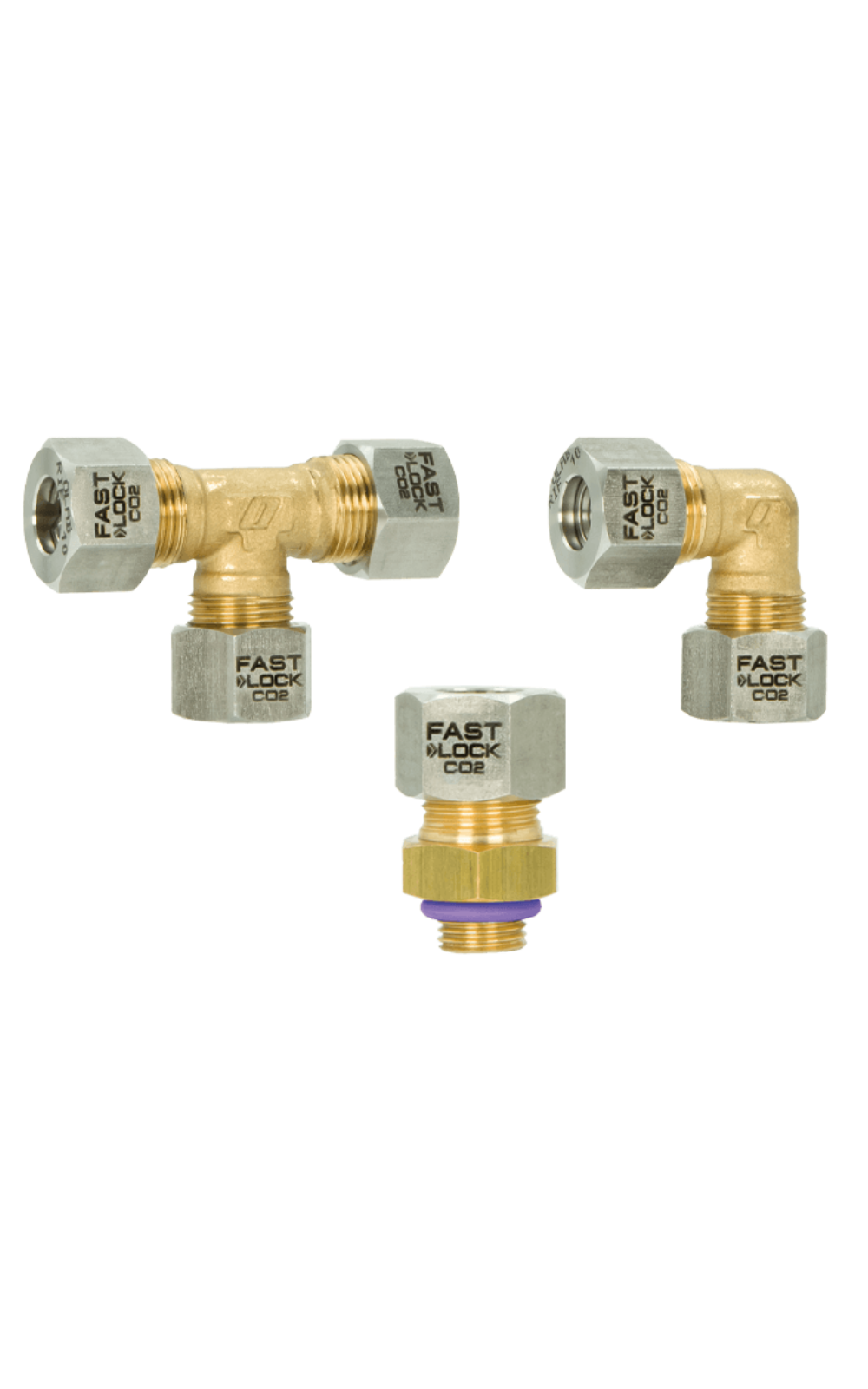

FASTLOCK CO2 FITTINGS FOR STAINLESS STEEL AND K65 PIPE - CW614N-OT58 BRASS BODY - AISI 316L STAINLESS STEEL NUT - FASTLOCK CO2 CONNECTION - 100% PFAS-FREE OLAB CERTIFIED EPDM O.RING

CHECK VALVE - BRASS BODY - FASTLOCK CO2 CONNECTION FOR STAINLESS STEEL AND K65 PIPE - 100% PFAS-FREE OLAB CERTIFIED EPDM O.RING

INNOVATIVE BRASS CHANGEOVER VALVE - FAST SYSTEM (PATENTED) COMPLETELY SWIVEL IN/OUT - COMPATIBLE WITH OLAB PROSHIELD SAFETY VALVES - STAINLESS STEEL CONTROL STEM - 100% PFAS-FREE OLAB CERTIFIED DOUBLE EPDM O.RING

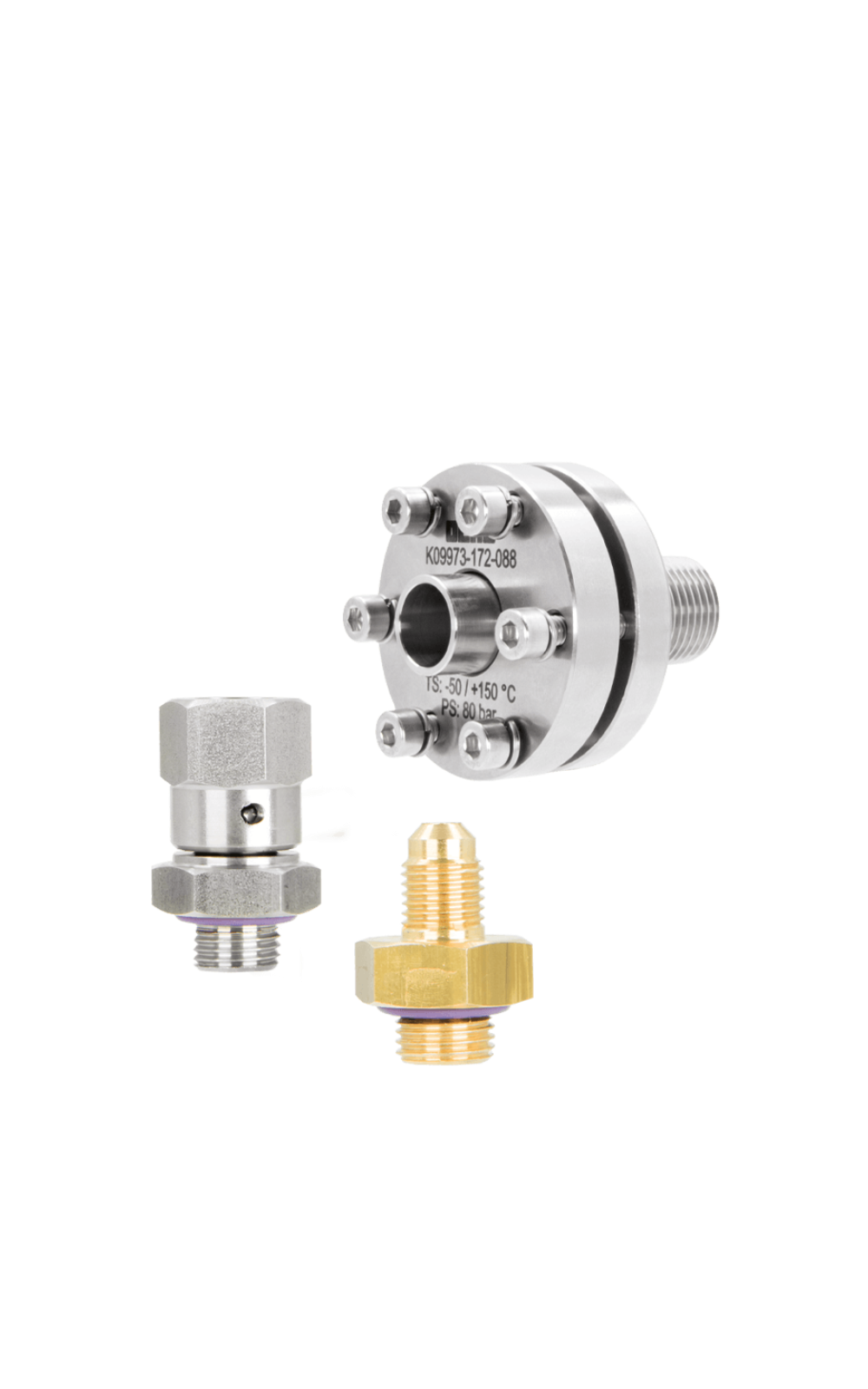

ROTATING FAST SYSTEM (PATENTED) HIGH PRESSURE RECEIVER VALVE FOR GAS CHARGE/DISCHARGE AND CONDENSATE DISCHARGE FOR HIGH PRESSURE CO2 SYSTEMS - CW617N-OT58 BODY - M GAS AND M SAE CONNECTION - OLAB CERTIFIED 100% PFAS-FREE EPDM O.RING

HIGH PRESSURE RECEIVER VALVE FOR HIGH-PRESSURE TANKS AND CONDITIONERS - BRASS BODY - STAINLESS STEEL CONTROL STEM - OLAB CERTIFIED 100% PFASFREE EPDM O.RING

FAST SYSTEM (PATENTED) HI-PRESSURE FITTINGS - BRASS OT STAINLESS STEEL - CYLINDRICAL OR FLANGED FAST SYSTEM (PATENTED) CONNECTION - OLAB CERTIFIED 100% PFAS-FREE EPDM O.RING

FAST SYSTEM (PATENTED) HI-PRESSURE MANIFOLDS - STAINLESS STEEL - TWO LATERAL INLETS - VARIABLE NUMBER OF VERTICAL OUTLET - DESIGNED FOR SERIES FAST SYSTEM (PATENTED) AND FASTLOCK CO2 FITTINGS

PATENTED ACCESS FITTING WITH DOUBLE O.RING CAP - BRASS BODY - 100% PFAS-FREE OLAB CERTIFIED EPDM O.RING

INNOVATIVE MOISTURE AND LIQUID INDICATOR - EN12164-CW614N-OT58 BRASS BODY - STAINLESS STEEL LOCKING RING - CRYSTAL INSPECTION GLASS - OLAB CERTIFIED 100% PFAS-FREE EPDM O.RING

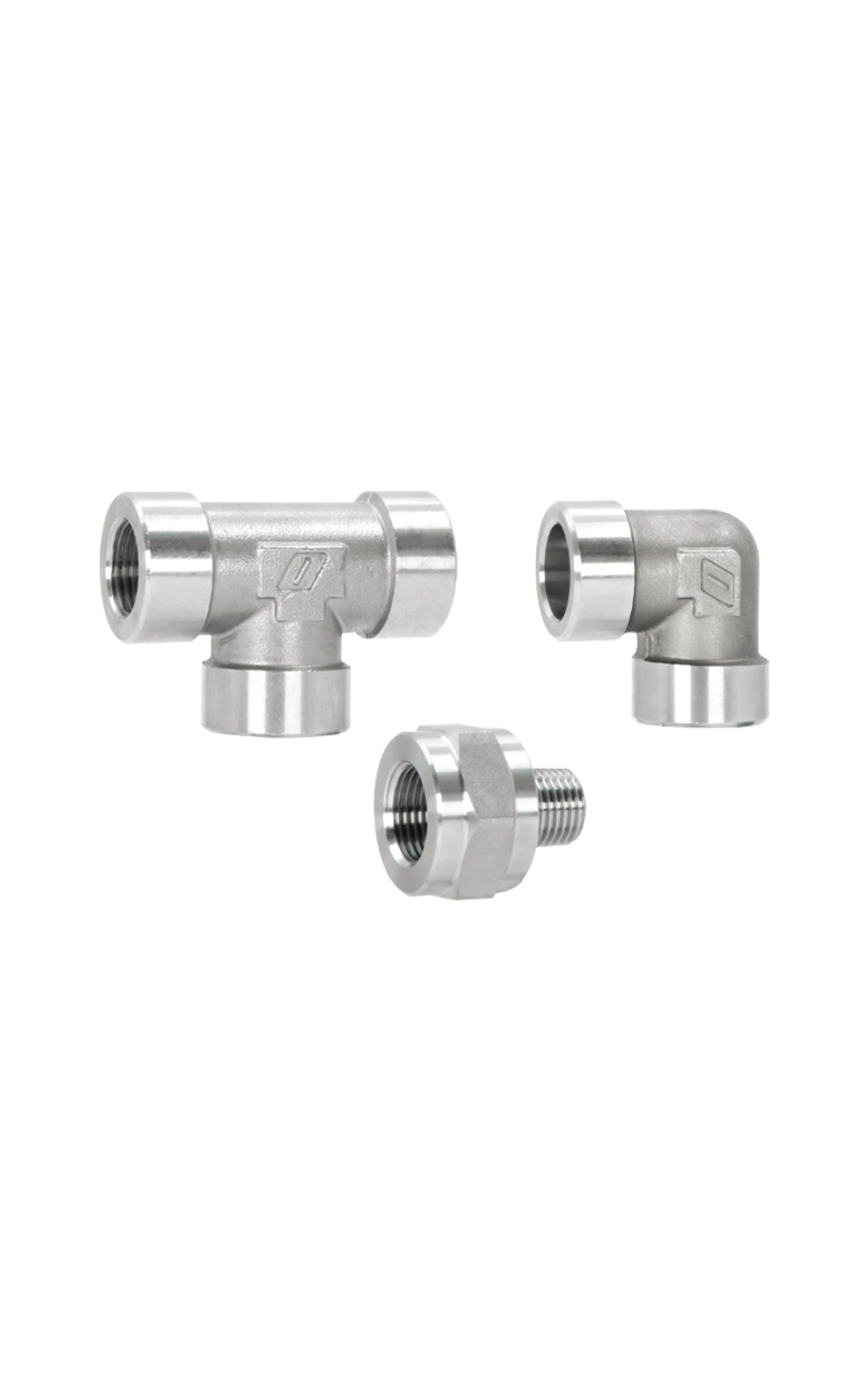

HI-PRESSURE CO2 FITTINGS - AISI 316L STAINLESS STEEL BODY - THREADED AND SOCKET WELDING CONNECTIONS

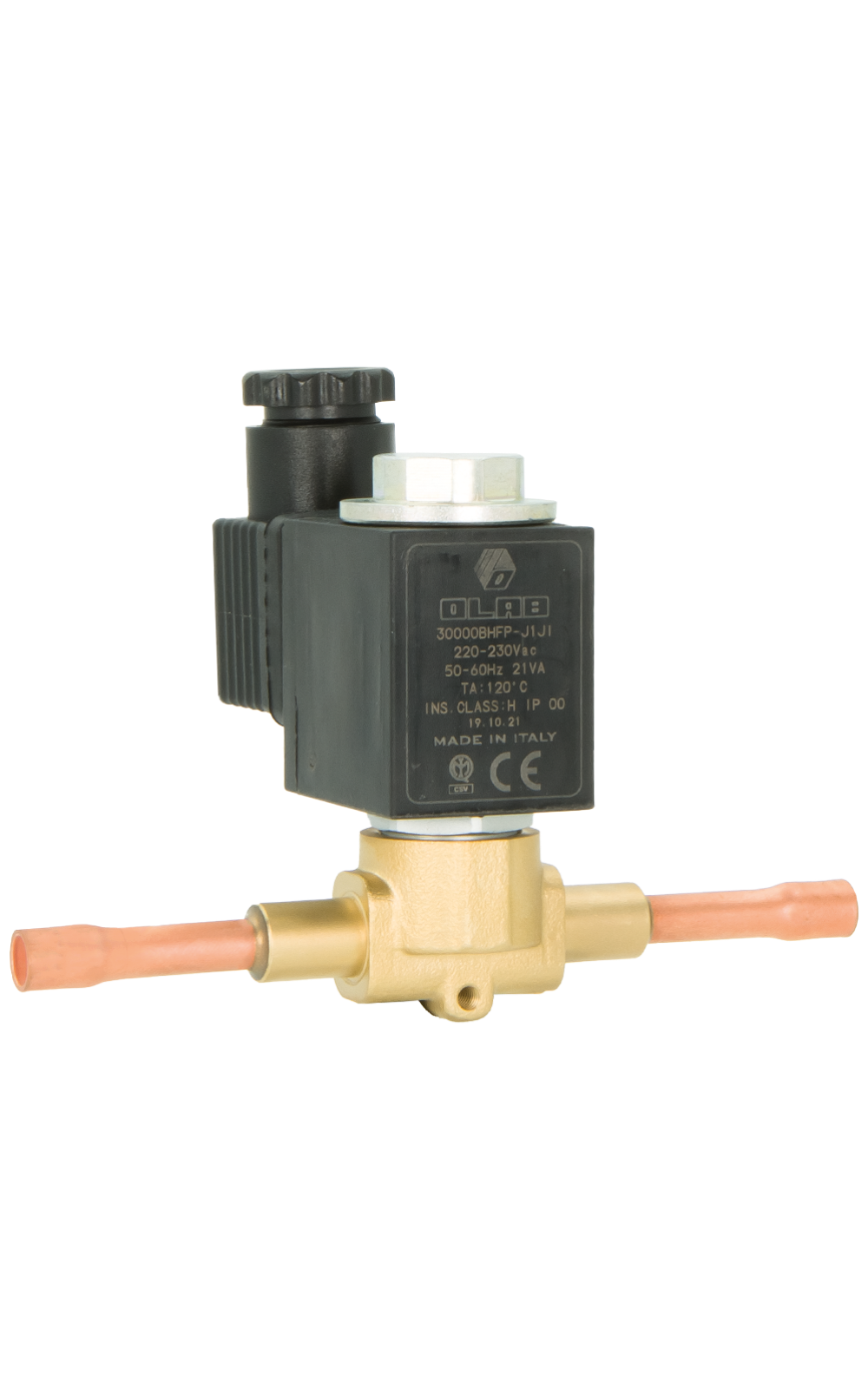

2/2-WAY N.C. BRASS SOLENOID VALVE - BRASS BODY - COPPER PIPES - STAINLESS STEEL SLEEVE - UL CERTIFIED 30MM Ø14 CLASS H COIL WITH IP67 CONNECTOR - OLAB CERTIFIED 100% PFAS-FREE EPDM O.RING