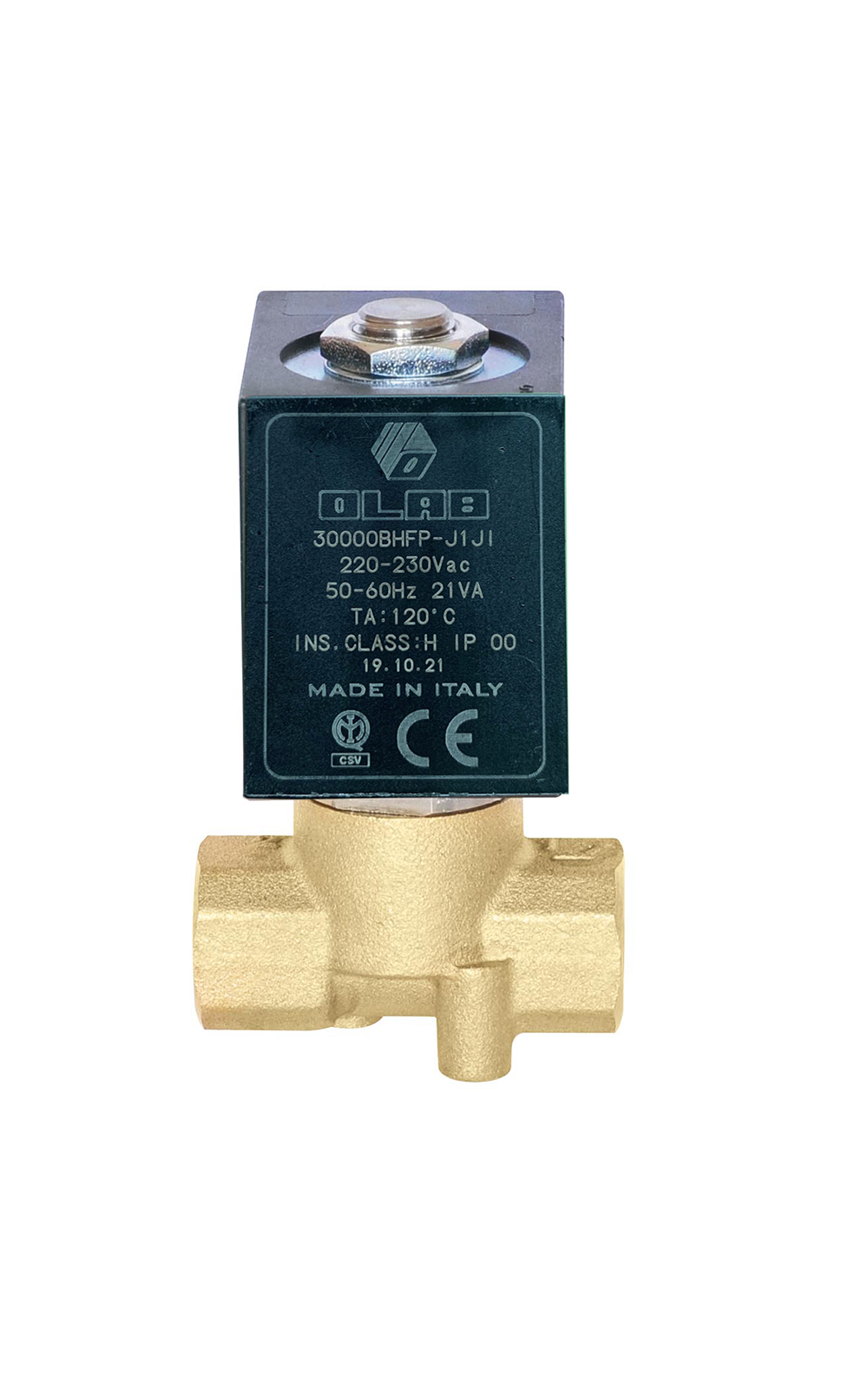

Category: DIRECT ACTION SOLENOID VALVES

Ways: 2/2 N.C.

Notes: SEALING IN PERFLUOROELASTOMER (FFKM) ENSURES HIGH RESISTANCE TO HEAT AND CHEMICAL AGENTS. THIS TYPE OF GASKET COMBINES THE EXCELLENT CHEMICAL RESISTANCE OF PTFE WITH THE ELASTIC BEHAVIOUR OF FKM

The 8201K

Series 2/2-way normally closed solenoid valve features a direct acting

mechanism and a fully stainless steel construction, with a sealing element

in perfluoroelastomer FFKM (Kalrez®). This gasket offers excellent

resistance to both high temperatures and aggressive chemical agents, combining

the chemical inertness of PTFE with the elastic behavior of FKM.

No minimum

pressure is required for activation, making it ideal for low-pressure circuits

or initial filling phases in professional hydraulic systems.

The valve

body is made of AISI 316 stainless steel, while the sleeve is

constructed from AISI 304 with a laser-welded fixed core, ensuring

long-lasting structural integrity. The openable design allows for easy

access to internal components for cleaning or maintenance.

The 30 mm Ø14

coil, insulation class H (up to 180°C), guarantees reliable operation in

extreme thermal environments.

This series

is engineered for use in demanding applications where high resistance to

corrosion and temperature is essential, with a working pressure up to 40 bar

(580 psi) and an operating temperature range from -15°C to +160°C.

The valve is also certified according to UL and VDE standards,

ensuring full compliance and operational safety in international contexts.

Technical features:

DIRECT

ACTION 2/2 WAYS NORMALLY CLOSED SOLENOID VALVES IN STAINLESS STEEL

Perfect for professional applications requiring zero-pressure activation and

high durability in aggressive fluids and environments.

OPENABLE

FOR INSPECTION AND INTERNAL COMPONENT MAINTENANCE

Accessible design allows easy inspection, cleaning and replacement of internal

parts.

HIGH-RESISTANCE

GASKET SEAL IN FFKM (KALREZ®)

Perfluoroelastomer sealing offering superior performance against high

temperatures and harsh chemicals.

AISI 316

STAINLESS STEEL BODY FOR MAXIMUM DURABILITY

Highly corrosion-resistant material ideal for harsh environments and critical

fluids.

AISI 304

STAINLESS STEEL SLEEVE WITH LASER-WELDED FIXED CORE

High manufacturing precision ensures long-term stability, reliability, and

performance.

30MM Ø14

COIL – CLASS H (180°C)

Engineered for high thermal stress environments, offering superior heat

resistance.

DESIGNED

FOR PROFESSIONAL HYDRAULIC CIRCUITS REQUIRING HIGH RESISTANCE TO CORROSION AND

TEMPERATURE

Built to perform reliably in demanding hydraulic systems exposed to corrosion

and thermal stress.

The 8201K

Series 2/2-way normally closed solenoid valve features a direct acting

mechanism and a fully stainless steel construction, with a sealing element

in perfluoroelastomer FFKM (Kalrez®). This gasket offers excellent

resistance to both high temperatures and aggressive chemical agents, combining

the chemical inertness of PTFE with the elastic behavior of FKM.

No minimum

pressure is required for activation, making it ideal for low-pressure circuits

or initial filling phases in professional hydraulic systems.

The valve

body is made of AISI 316 stainless steel, while the sleeve is

constructed from AISI 304 with a laser-welded fixed core, ensuring

long-lasting structural integrity. The openable design allows for easy

access to internal components for cleaning or maintenance.

The 30 mm Ø14

coil, insulation class H (up to 180°C), guarantees reliable operation in

extreme thermal environments.

This series

is engineered for use in demanding applications where high resistance to

corrosion and temperature is essential, with a working pressure up to 40 bar

(580 psi) and an operating temperature range from -15°C to +160°C.

The valve is also certified according to UL and VDE standards,

ensuring full compliance and operational safety in international contexts.

Technical features:

DIRECT

ACTION 2/2 WAYS NORMALLY CLOSED SOLENOID VALVES IN STAINLESS STEEL

Perfect for professional applications requiring zero-pressure activation and

high durability in aggressive fluids and environments.

OPENABLE

FOR INSPECTION AND INTERNAL COMPONENT MAINTENANCE

Accessible design allows easy inspection, cleaning and replacement of internal

parts.

HIGH-RESISTANCE

GASKET SEAL IN FFKM (KALREZ®)

Perfluoroelastomer sealing offering superior performance against high

temperatures and harsh chemicals.

AISI 316

STAINLESS STEEL BODY FOR MAXIMUM DURABILITY

Highly corrosion-resistant material ideal for harsh environments and critical

fluids.

AISI 304

STAINLESS STEEL SLEEVE WITH LASER-WELDED FIXED CORE

High manufacturing precision ensures long-term stability, reliability, and

performance.

30MM Ø14

COIL – CLASS H (180°C)

Engineered for high thermal stress environments, offering superior heat

resistance.

DESIGNED

FOR PROFESSIONAL HYDRAULIC CIRCUITS REQUIRING HIGH RESISTANCE TO CORROSION AND

TEMPERATURE

Built to perform reliably in demanding hydraulic systems exposed to corrosion

and thermal stress.