Ways: 3/2 N.C.

Notes:

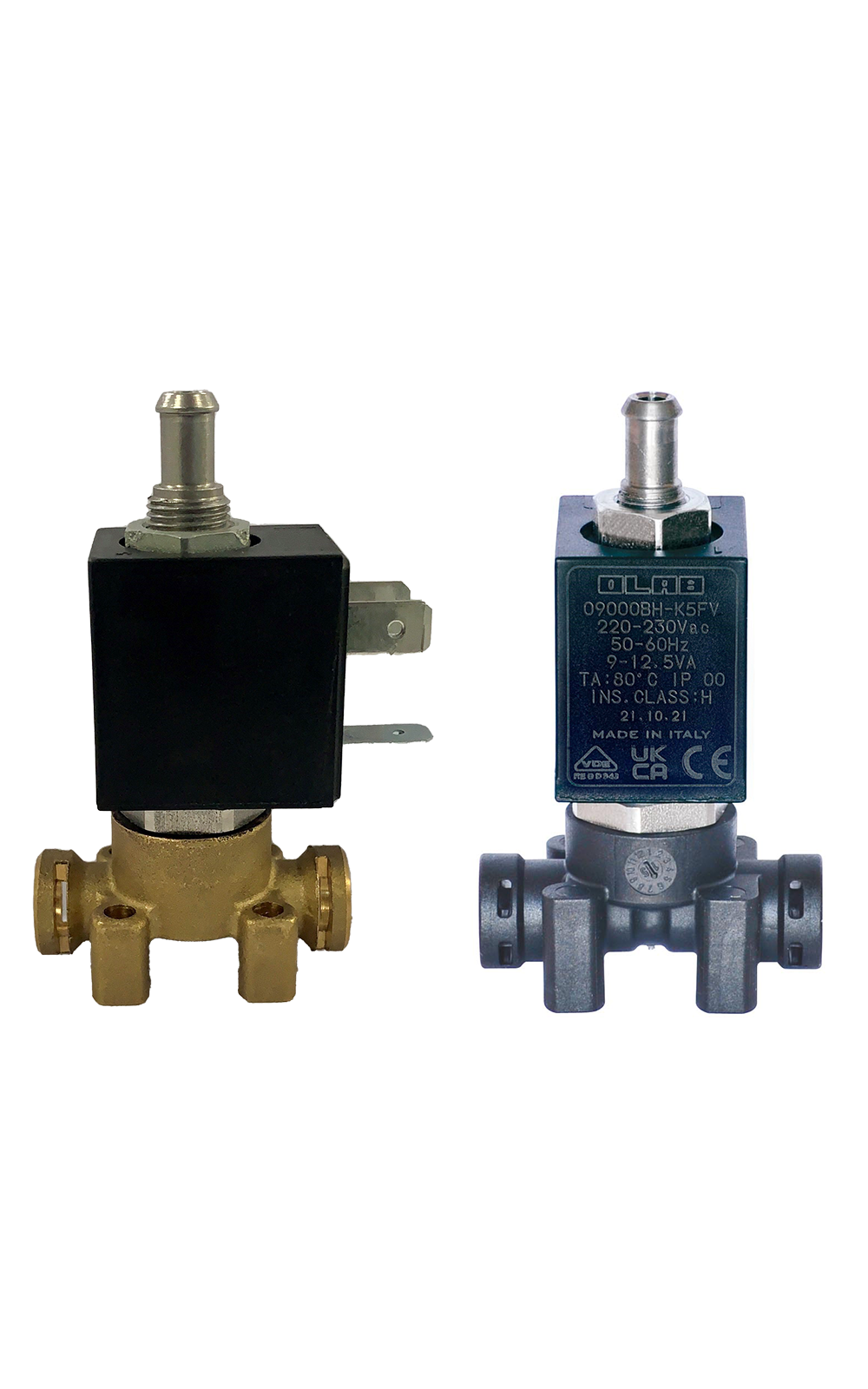

The 9900K-K09775L

Series is a 3/2-way normally closed direct-acting solenoid valve,

specifically designed for semi-professional hydraulic and pneumatic circuits

where compatibility with food-grade fluids is essential, along with a compact,

versatile, and easily serviceable design. It is available in two versions: food-grade

technopolymer body (model 9900K) or CW510L-OT57 NSF USA brass body

(model K09775L). Both versions feature OLAB-certified RBX

high-performance seals, ensuring excellent sealing and chemical resistance

even under demanding conditions.

The direct-acting

mechanism enables the valve to operate without the need for minimum

pressure, making it highly versatile in low-pressure systems or with

non-compressible fluids. The inspectable structure allows for quick

access to internal components, simplifying maintenance and cleaning while

ensuring system continuity.

Equipped

with fast connections for 4 mm Teflon tubes with pre-installed ferrules,

the valve ensures quick, reliable installation and reduces assembly time.

The 9000BH

coil (22 mm Ø10, insulation class H – 180°C) offers a compact solution

for space-constrained systems, maintaining high performance without

compromising footprint.

The technopolymer

version (9900K) is rated for up to 20 bar (290 psi) and operates in

a temperature range from –15°C to +135°C (+5°F ÷ +275°F). The brass

version (K09775L) supports pressures up to 30 bar (435 psi) and

temperatures from –15°C to +160°C (+5°F ÷ +320°F).

Both models are CE, UL,

VDE, and MOCA certified, ensuring full compliance with international

standards for electrical safety, food-contact compatibility, and material

reliability.

Technical features:

SUITABLE FOR FOOD-CONTACT FLUIDS

Manufactured with a CW510L-OT57NSF USA brass body or food-grade technopolymer and OLAB-certified RBX seals, ensuring full compliance with hygienic standards for food and beverage applications.

DIRECT ACTUATION WITHOUT MINIMUM PRESSURE

Operates without requiring a pressure differential, offering maximum versatility even in low-pressure systems or with non-compressible fluids.

FAST CONNECTIONS FOR Ø4 MM TEFLON TUBES WITH PRE-INSTALLED FERRULES

Quick-connect system designed for 4 mm PTFE tubes with pre-mounted ferrules, ensuring fast installation, reliable sealing, and reduced assembly time.

INSPECTABLE DESIGN FOR EASY MAINTENANCE

The valve can be opened for internal cleaning or component replacement, streamlining maintenance and ensuring long-term functionality.

EXCELLENT VALUE FOR MONEY

A reliable solution made from certified, high-performance materials, offering outstanding quality at a competitive cost for semi-professional use.

COMPACT 22 MM COIL FOR SPACE-SAVING INSTALLATION

Equipped with a 22 mm Ø10 coil in insulation class H (180°C), the valve is ideal for tight installation spaces without compromising performance.

The 9900K-K09775L

Series is a 3/2-way normally closed direct-acting solenoid valve,

specifically designed for semi-professional hydraulic and pneumatic circuits

where compatibility with food-grade fluids is essential, along with a compact,

versatile, and easily serviceable design. It is available in two versions: food-grade

technopolymer body (model 9900K) or CW510L-OT57 NSF USA brass body

(model K09775L). Both versions feature OLAB-certified RBX

high-performance seals, ensuring excellent sealing and chemical resistance

even under demanding conditions.

The direct-acting

mechanism enables the valve to operate without the need for minimum

pressure, making it highly versatile in low-pressure systems or with

non-compressible fluids. The inspectable structure allows for quick

access to internal components, simplifying maintenance and cleaning while

ensuring system continuity.

Equipped

with fast connections for 4 mm Teflon tubes with pre-installed ferrules,

the valve ensures quick, reliable installation and reduces assembly time.

The 9000BH

coil (22 mm Ø10, insulation class H – 180°C) offers a compact solution

for space-constrained systems, maintaining high performance without

compromising footprint.

The technopolymer

version (9900K) is rated for up to 20 bar (290 psi) and operates in

a temperature range from –15°C to +135°C (+5°F ÷ +275°F). The brass

version (K09775L) supports pressures up to 30 bar (435 psi) and

temperatures from –15°C to +160°C (+5°F ÷ +320°F).

Both models are CE, UL,

VDE, and MOCA certified, ensuring full compliance with international

standards for electrical safety, food-contact compatibility, and material

reliability.

Technical features:

SUITABLE FOR FOOD-CONTACT FLUIDS

Manufactured with a CW510L-OT57NSF USA brass body or food-grade technopolymer and OLAB-certified RBX seals, ensuring full compliance with hygienic standards for food and beverage applications.

DIRECT ACTUATION WITHOUT MINIMUM PRESSURE

Operates without requiring a pressure differential, offering maximum versatility even in low-pressure systems or with non-compressible fluids.

FAST CONNECTIONS FOR Ø4 MM TEFLON TUBES WITH PRE-INSTALLED FERRULES

Quick-connect system designed for 4 mm PTFE tubes with pre-mounted ferrules, ensuring fast installation, reliable sealing, and reduced assembly time.

INSPECTABLE DESIGN FOR EASY MAINTENANCE

The valve can be opened for internal cleaning or component replacement, streamlining maintenance and ensuring long-term functionality.

EXCELLENT VALUE FOR MONEY

A reliable solution made from certified, high-performance materials, offering outstanding quality at a competitive cost for semi-professional use.

COMPACT 22 MM COIL FOR SPACE-SAVING INSTALLATION

Equipped with a 22 mm Ø10 coil in insulation class H (180°C), the valve is ideal for tight installation spaces without compromising performance.