Category: CO2 (R744) SPECIALIST

Notes:

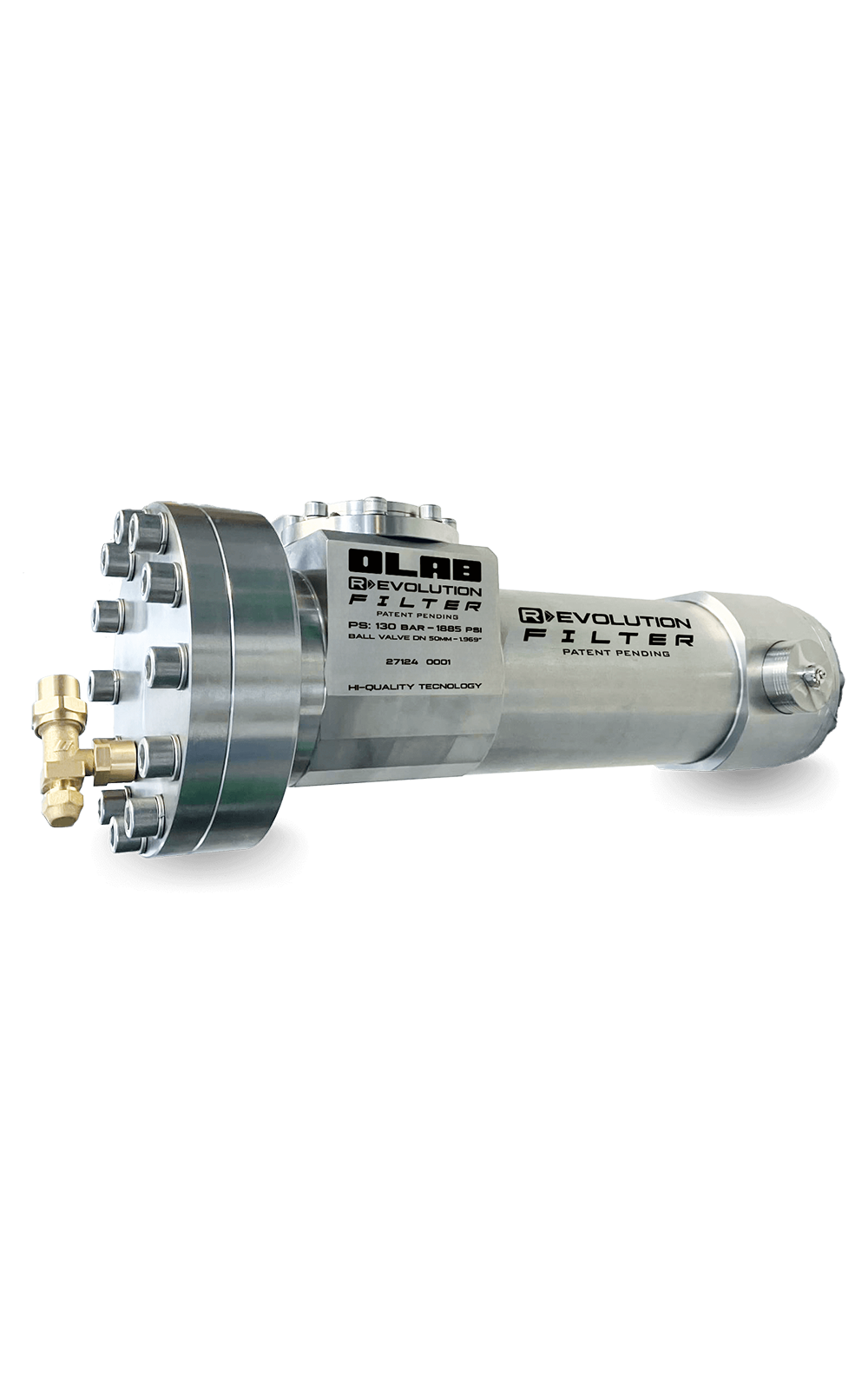

Series

Revolution Filter

is the stainless steel flanged filter developed by OLAB for high-pressure

CO2 (R744) systems, where filtration, sealing, and maneuverability

must operate in full safety, ensuring cost-efficiency and full compliance with

modern environmental sustainability standards.

The entire

structure is machined from solid corrosion-resistant stainless steel,

with no structural welds. A single high-precision mechanical process

shapes both the filter body and the integrated Series Revolution ball valve

on the outlet side, while the AISI 316L stainless steel flanges ensure

reliable, durable connections across the system.

This

monolithic construction eliminates all structural weak points. Combined

with a dual radial front EPDM O-Ring, 100% PFAS-free and

OLAB-certified, it guarantees permanent leak-tightness under all

operating conditions: 150 bar working pressure (2175 psi) with a Safety Factor 3, 450 bar burst pressure (6527 psi), and a temperature

range from –50 °C to +150 °C (–58 °F ÷ +302 °F).

The AISI 316 stainless steel mesh filter traps particles and impurities,

while the high-pressure rotating Fastech receiver valve enables quick and

safe maintenance, purging, and inspection.

Fully compatible with the Series Revolution valve line,

the filter can be equipped with a second valve on the inlet side thanks to its modular

flange system, giving operators complete control over both input and

output. Once installed, the flanges are welded only once; the filter body can

then be removed and replaced in-line, without cutting, without

rewelding, and without the need for specialized personnel. At the end of its service life, the filter body can be

returned to OLAB for regeneration — a smart, sustainable solution that

reduces operating costs and environmental impact as a low-PFAS components.

With a nominal diameter of DN 50 (1.969”), CE, UL 207

certification, and a full stainless steel construction with intrinsic

corrosion resistance, Series Revolution Filter is the ideal choice for

CO2 high-pressure systems requiring long-term reliability, simplified

maintenance, and maximum operational safety.

Technical features:

UL 207

CERTIFIED

FULLY

MACHINED FROM FULL STAINLESS STEEL BAR

Using high-precision equipment, with all components assembled using

A2-grade stainless steel screws.

NO STRUCTURAL WELDS

Eliminating long-term sealing issues or

deformation risks.

INHERENTLY CORROSION-RESISTANT

Built for durability and harsh

environments.

100% NO LEAKAGE

Permanent, certified leak-tightness.

A quality solution that’s reliable, efficient, cost-effective – and 100% green.

150 BAR / 2175 PSI GUARANTEED

Designed and verified with a 3x safety

factor (450 BAR / 6527 PSI).

DOUBLE EPDM O-RING 100% PFAS-FREE OLAB-CERTIFIED

Winner of the Innovation

of the Year at ATMOSummit Europe 2024: guaranteed sealing at every

potential leakage point.

INTEGRATED SERIES REVOLUTION BALL VALVE AND FASTECH

HIGH-PRESSURE RECEIVER VALVE

MODULAR FLANGE SYSTEM

Add a second Series Revolution ball valve on the

inlet for full flow control.

EASY AND SAFE INSTALLATION OR REPLACEMENT

No pipe cutting or rewelding

required.

REGENERABLE FILTER BODY

Send it back to OLAB at the end of its service

life – reduce waste, save cost.

Series

Revolution Filter

is the stainless steel flanged filter developed by OLAB for high-pressure

CO2 (R744) systems, where filtration, sealing, and maneuverability

must operate in full safety, ensuring cost-efficiency and full compliance with

modern environmental sustainability standards.

The entire

structure is machined from solid corrosion-resistant stainless steel,

with no structural welds. A single high-precision mechanical process

shapes both the filter body and the integrated Series Revolution ball valve

on the outlet side, while the AISI 316L stainless steel flanges ensure

reliable, durable connections across the system.

This

monolithic construction eliminates all structural weak points. Combined

with a dual radial front EPDM O-Ring, 100% PFAS-free and

OLAB-certified, it guarantees permanent leak-tightness under all

operating conditions: 150 bar working pressure (2175 psi) with a Safety Factor 3, 450 bar burst pressure (6527 psi), and a temperature

range from –50 °C to +150 °C (–58 °F ÷ +302 °F).

The AISI 316 stainless steel mesh filter traps particles and impurities,

while the high-pressure rotating Fastech receiver valve enables quick and

safe maintenance, purging, and inspection.

Fully compatible with the Series Revolution valve line,

the filter can be equipped with a second valve on the inlet side thanks to its modular

flange system, giving operators complete control over both input and

output. Once installed, the flanges are welded only once; the filter body can

then be removed and replaced in-line, without cutting, without

rewelding, and without the need for specialized personnel. At the end of its service life, the filter body can be

returned to OLAB for regeneration — a smart, sustainable solution that

reduces operating costs and environmental impact as a low-PFAS components.

With a nominal diameter of DN 50 (1.969”), CE, UL 207

certification, and a full stainless steel construction with intrinsic

corrosion resistance, Series Revolution Filter is the ideal choice for

CO2 high-pressure systems requiring long-term reliability, simplified

maintenance, and maximum operational safety.

Technical features:

UL 207

CERTIFIED

FULLY

MACHINED FROM FULL STAINLESS STEEL BAR

Using high-precision equipment, with all components assembled using

A2-grade stainless steel screws.

NO STRUCTURAL WELDS

Eliminating long-term sealing issues or

deformation risks.

INHERENTLY CORROSION-RESISTANT

Built for durability and harsh

environments.

100% NO LEAKAGE

Permanent, certified leak-tightness.

A quality solution that’s reliable, efficient, cost-effective – and 100% green.

150 BAR / 2175 PSI GUARANTEED

Designed and verified with a 3x safety

factor (450 BAR / 6527 PSI).

DOUBLE EPDM O-RING 100% PFAS-FREE OLAB-CERTIFIED

Winner of the Innovation

of the Year at ATMOSummit Europe 2024: guaranteed sealing at every

potential leakage point.

INTEGRATED SERIES REVOLUTION BALL VALVE AND FASTECH

HIGH-PRESSURE RECEIVER VALVE

MODULAR FLANGE SYSTEM

Add a second Series Revolution ball valve on the

inlet for full flow control.

EASY AND SAFE INSTALLATION OR REPLACEMENT

No pipe cutting or rewelding

required.

REGENERABLE FILTER BODY

Send it back to OLAB at the end of its service

life – reduce waste, save cost.