Ways: 2/2

Notes:

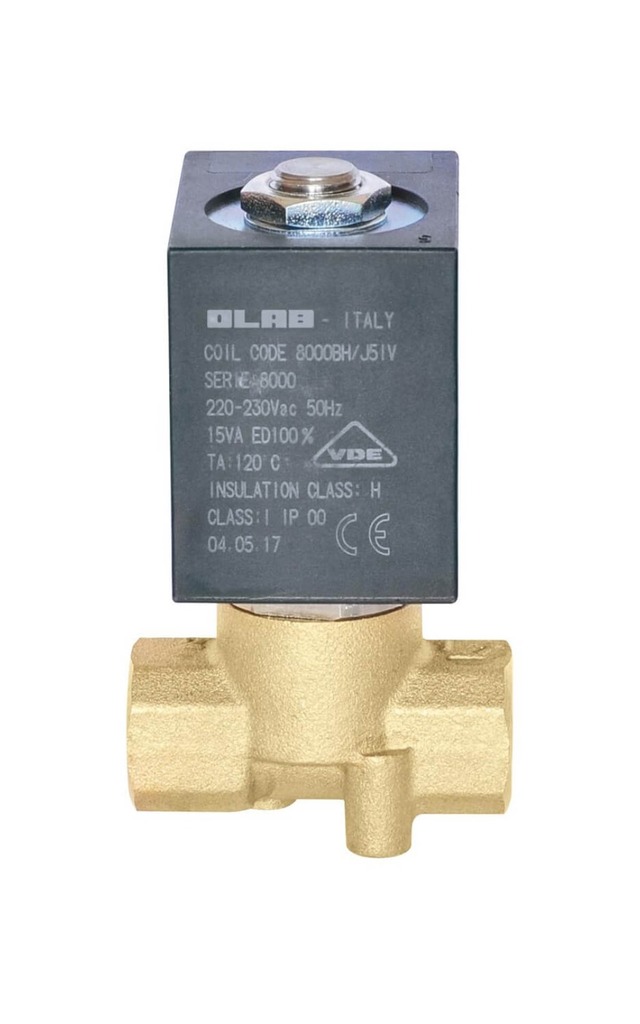

The 08201

Series is a 2/2-way normally closed direct-acting solenoid valve,

specifically designed to ensure maximum reliability in professional

hydraulic systems, even under demanding conditions or low-pressure

operation. Its inspectable construction and the high quality of its

components make it the ideal solution for applications requiring consistent

performance, long service life, and easy maintenance.

The valve

features a forged yellow brass body (EN12165-CW617N), a laser-welded

AISI 304L stainless steel sleeve with fixed core, AISI 430F stainless

steel cores, a DN insert in AISI 303, and an AISI 302 stainless

steel spring—a combination that guarantees mechanical strength,

operational stability, and long-term durability, even in aggressive

environments. The OLAB-certified sealing gaskets are available in EPDM,

RBX for food-contact, and high-performance RBX for food-contact,

offering excellent chemical compatibility and temperature resistance.

With its direct-acting design, the valve operates without

requiring minimum pressure, ensuring maximum flexibility in systems with

variable flow or non-compressible fluids. The inspectable structure

allows easy access to internal components, simplifying cleaning and part

replacement while minimizing downtime.

Equipped with a 30 mm Ø14 8000BH coil, insulation class H

(180°C), the 8201 Series delivers stable thermal performance and

consistent operation even under harsh conditions. Its compact design

supports easy integration into tight spaces.

Rated for a maximum pressure of 40 bar (582 psi) and

suitable for temperatures ranging from –15°C to +160°C (+5°F to +320°F),

the 8201 Series is CE, UL and VDE certified, ensuring full compliance

with international standards for electrical safety and product quality.

Technical features:

Air, water, steam, industrial automation, car washes, compressors, industrial washing, food & beverage. Other fluids after checking compatibility.

DIRECT

ACTUATION WITHOUT MINIMUM PRESSURE

Operates reliably without the need for differential pressure, ensuring maximum

flexibility even in low-pressure or variable flow conditions.

IDEAL FOR PROFESSIONAL APPLICATIONS

Designed to meet the demands of professional hydraulic systems, delivering

consistent performance and long-lasting durability.

INSPECTABLE DESIGN FOR EASY MAINTENANCE

The valve allows internal access for cleaning or replacement of components,

simplifying service and reducing system downtime.

AISI 304 STAINLESS STEEL INSERT FOR MAXIMUM WEAR

RESISTANCE

Equipped with a high-grade stainless steel DN insert to ensure excellent

durability and resistance to mechanical stress over time.

The 08201

Series is a 2/2-way normally closed direct-acting solenoid valve,

specifically designed to ensure maximum reliability in professional

hydraulic systems, even under demanding conditions or low-pressure

operation. Its inspectable construction and the high quality of its

components make it the ideal solution for applications requiring consistent

performance, long service life, and easy maintenance.

The valve

features a forged yellow brass body (EN12165-CW617N), a laser-welded

AISI 304L stainless steel sleeve with fixed core, AISI 430F stainless

steel cores, a DN insert in AISI 303, and an AISI 302 stainless

steel spring—a combination that guarantees mechanical strength,

operational stability, and long-term durability, even in aggressive

environments. The OLAB-certified sealing gaskets are available in EPDM,

RBX for food-contact, and high-performance RBX for food-contact,

offering excellent chemical compatibility and temperature resistance.

With its direct-acting design, the valve operates without

requiring minimum pressure, ensuring maximum flexibility in systems with

variable flow or non-compressible fluids. The inspectable structure

allows easy access to internal components, simplifying cleaning and part

replacement while minimizing downtime.

Equipped with a 30 mm Ø14 8000BH coil, insulation class H

(180°C), the 8201 Series delivers stable thermal performance and

consistent operation even under harsh conditions. Its compact design

supports easy integration into tight spaces.

Rated for a maximum pressure of 40 bar (582 psi) and

suitable for temperatures ranging from –15°C to +160°C (+5°F to +320°F),

the 8201 Series is CE, UL and VDE certified, ensuring full compliance

with international standards for electrical safety and product quality.

Technical features:

Air, water, steam, industrial automation, car washes, compressors, industrial washing, food & beverage. Other fluids after checking compatibility.

DIRECT

ACTUATION WITHOUT MINIMUM PRESSURE

Operates reliably without the need for differential pressure, ensuring maximum

flexibility even in low-pressure or variable flow conditions.

IDEAL FOR PROFESSIONAL APPLICATIONS

Designed to meet the demands of professional hydraulic systems, delivering

consistent performance and long-lasting durability.

INSPECTABLE DESIGN FOR EASY MAINTENANCE

The valve allows internal access for cleaning or replacement of components,

simplifying service and reducing system downtime.

AISI 304 STAINLESS STEEL INSERT FOR MAXIMUM WEAR

RESISTANCE

Equipped with a high-grade stainless steel DN insert to ensure excellent

durability and resistance to mechanical stress over time.