Category: TRADITIONAL REFRIGERATION SYSTEMS

Notes:

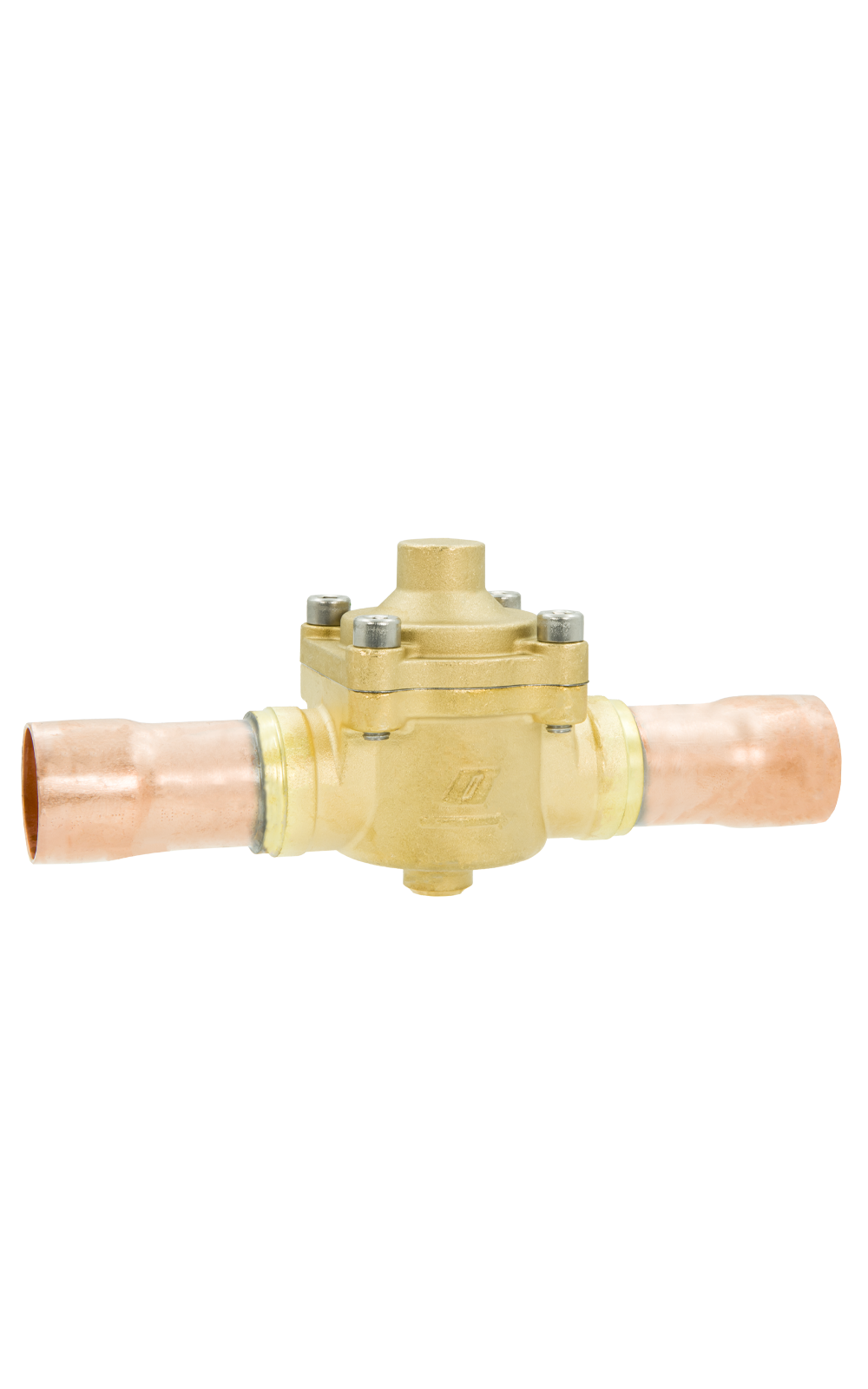

The Series

33000–33100 consist of check valves specifically designed for

professional A1 refrigeration systems, where reliability, sealing performance,

and durability are critical.

The yellow brass body and copper tubes

ensure a solid and long-lasting construction, even under demanding operating

conditions. The sealing element, made of PTFE and NBR bonded to a

rubber-coated metal washer, delivers a secure and long-term hermetic

seal.

These

valves are available with calibrated cracking pressure differentials of 0.1

– 0.3 – 1.5 bar, offering flexibility for various system configurations and

pressure balancing needs.

Designed to ensure extended service life and low

pressure drops, they deliver consistently stable performance across all

applications.

Each unit

undergoes 100% helium leak testing, and laser marking of the date

and serial number ensures permanent traceability of tested performance

data. The Series 33000 and 33100 operate in wide temperature ranges of –35°C

÷ +105°C (–31°F ÷ +221°F) and –40°C ÷ +150°C (–40°F ÷ +302°F)

respectively, and withstand pressures up to 45 bar (652 psi). Fully

CE certified, these check valves are a safe, professional-grade solution

for high-performance refrigeration systems.

Technical features:

COMPATIBLE A1 REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a

HFO e miscele HFO/HFC: R1234ze, R448A, R449A, R450A, R452A, R1234yf, R1233zdOur Neoprene compound gaskets have been designed and produced to be compatible with group A1 refrigerant gases (as defined in ASHRAE standard 34).However, in consideration of the infinite application variables (pressure, temperature and mixing percentages), an application check on the system is always required.

RELIABLE DURABILITY

Body made of yellow brass, engineered to ensure strength and long-term resistance even under demanding conditions.

SECURE AND CONSISTENT SEALING

Sealing element in PTFE and NBR rubberized sheet, providing perfect airtightness in all conditions.

TAILORED OPENING PRESSURES

Available with differential opening pressures of 0.1 – 0.3 – 1.5 bar, to meet various system requirements. A higher-pressure differential will increase the flow rate.

100% HELIUM TESTED

Each unit is individually tested in a state-of-the-art helium facility. Date and serial number are engraved to certify compliance and allow full traceability of recorded performance data.

At the start-up of circuit is good to be sure that there are not dust or contamination inside the pipes. The arrow direction on body valve should be in accord with the flow direction inside the circuit. All mounting positions are accepted, even if is better to be in accord with the vertical axis. For 33100 series is accepted only the installation with orizontal axis. The braze welding of copper tubes should made by special alloy, with low melting point. The flame should not be directed toward the seals or body of valve, because it can damage the valve in consequence of overheating.

The Series

33000–33100 consist of check valves specifically designed for

professional A1 refrigeration systems, where reliability, sealing performance,

and durability are critical.

The yellow brass body and copper tubes

ensure a solid and long-lasting construction, even under demanding operating

conditions. The sealing element, made of PTFE and NBR bonded to a

rubber-coated metal washer, delivers a secure and long-term hermetic

seal.

These

valves are available with calibrated cracking pressure differentials of 0.1

– 0.3 – 1.5 bar, offering flexibility for various system configurations and

pressure balancing needs.

Designed to ensure extended service life and low

pressure drops, they deliver consistently stable performance across all

applications.

Each unit

undergoes 100% helium leak testing, and laser marking of the date

and serial number ensures permanent traceability of tested performance

data. The Series 33000 and 33100 operate in wide temperature ranges of –35°C

÷ +105°C (–31°F ÷ +221°F) and –40°C ÷ +150°C (–40°F ÷ +302°F)

respectively, and withstand pressures up to 45 bar (652 psi). Fully

CE certified, these check valves are a safe, professional-grade solution

for high-performance refrigeration systems.

Technical features:

COMPATIBLE A1 REFRIGERANT GASES

HFC, HFO, and HFO/HFC blends: R404A, R407C, R410A, R507, R32, R134a

HFO e miscele HFO/HFC: R1234ze, R448A, R449A, R450A, R452A, R1234yf, R1233zdOur Neoprene compound gaskets have been designed and produced to be compatible with group A1 refrigerant gases (as defined in ASHRAE standard 34).However, in consideration of the infinite application variables (pressure, temperature and mixing percentages), an application check on the system is always required.

RELIABLE DURABILITY

Body made of yellow brass, engineered to ensure strength and long-term resistance even under demanding conditions.

SECURE AND CONSISTENT SEALING

Sealing element in PTFE and NBR rubberized sheet, providing perfect airtightness in all conditions.

TAILORED OPENING PRESSURES

Available with differential opening pressures of 0.1 – 0.3 – 1.5 bar, to meet various system requirements. A higher-pressure differential will increase the flow rate.

100% HELIUM TESTED

Each unit is individually tested in a state-of-the-art helium facility. Date and serial number are engraved to certify compliance and allow full traceability of recorded performance data.

At the start-up of circuit is good to be sure that there are not dust or contamination inside the pipes. The arrow direction on body valve should be in accord with the flow direction inside the circuit. All mounting positions are accepted, even if is better to be in accord with the vertical axis. For 33100 series is accepted only the installation with orizontal axis. The braze welding of copper tubes should made by special alloy, with low melting point. The flame should not be directed toward the seals or body of valve, because it can damage the valve in consequence of overheating.