Category: TRADITIONAL REFRIGERATION SYSTEMS

Surface treatments applicable: no

Notes: 0

The receiver for split air conditioners is designed to withstand 1.43 times the PS according to the standards set by the Directive 2014/68 / UE. In addition, laboratory tests certify the resistance of the receiver to bursting pressure equal to 3xPS in accordaN.C.e with EN 378-2: 2016.

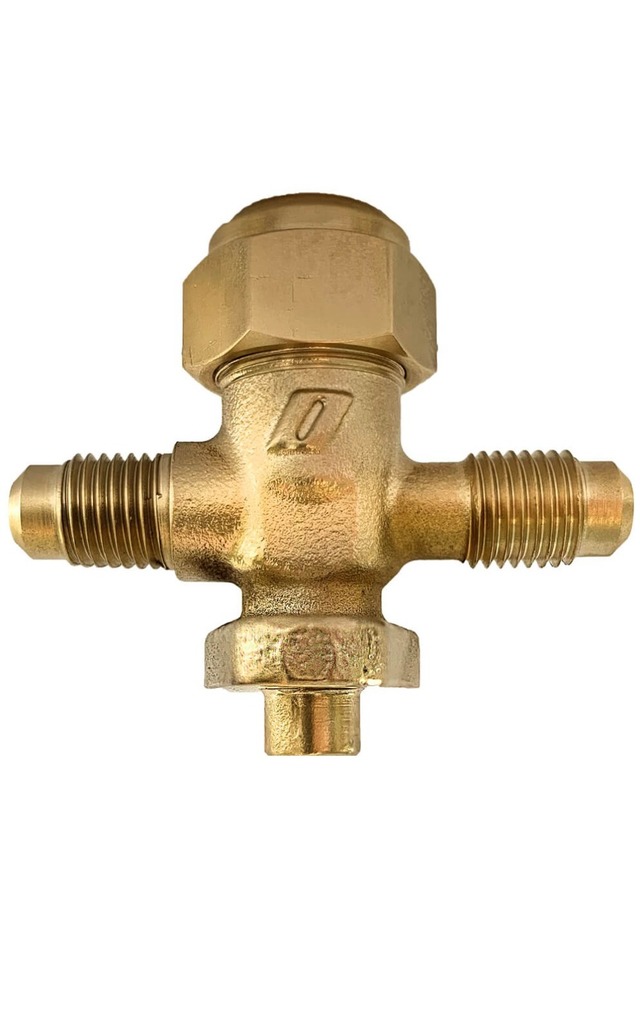

The stop valves for split conditioning systems in the series 43001 are designed to be in-stalled on refrigeration

and air-conditioning system for domestic and industrial use. It’s possible to use them with all the refrigerant fluids

of goup 2 of Art.13, Chapter 1, point B, of Euopean Directive 2014/68/EU, with reference to EC Regulation no.

1272/2008.

Below i s a list of the main refrigerant gases that can be used:

Make sure the refrigeration/conditioning system is properly clean before installing the valve with a three-way screw plug. The presence of impurities could affect the sealing of the valve. Valve opening/closing is very easy: you only need to remove the protection cover and rotate the pin clockwise to close the valve and anti-clockwise to open it, using an Allen wrench. Then remount the protection cover. Braze welding between the pipes and the valve is performed by using heating. The presence of seals in the valve requires the fitter to pay particular attention in avoiding to direct the flame towards the valve body and sealing areas in general. We recommend protecting the valve body with a wet cloth during this operation. Before installing the valve, it is advisable to carefully read the instruction leaflet contained in each package.

The receiver for split air conditioners is designed to withstand 1.43 times the PS according to the standards set by the Directive 2014/68 / UE. In addition, laboratory tests certify the resistance of the receiver to bursting pressure equal to 3xPS in accordaN.C.e with EN 378-2: 2016.

The stop valves for split conditioning systems in the series 43001 are designed to be in-stalled on refrigeration

and air-conditioning system for domestic and industrial use. It’s possible to use them with all the refrigerant fluids

of goup 2 of Art.13, Chapter 1, point B, of Euopean Directive 2014/68/EU, with reference to EC Regulation no.

1272/2008.

Below i s a list of the main refrigerant gases that can be used:

Make sure the refrigeration/conditioning system is properly clean before installing the valve with a three-way screw plug. The presence of impurities could affect the sealing of the valve. Valve opening/closing is very easy: you only need to remove the protection cover and rotate the pin clockwise to close the valve and anti-clockwise to open it, using an Allen wrench. Then remount the protection cover. Braze welding between the pipes and the valve is performed by using heating. The presence of seals in the valve requires the fitter to pay particular attention in avoiding to direct the flame towards the valve body and sealing areas in general. We recommend protecting the valve body with a wet cloth during this operation. Before installing the valve, it is advisable to carefully read the instruction leaflet contained in each package.